This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

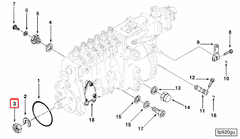

The Gear Retaining Nut, identified by Part #3912896, is a component manufactured by Cummins, a renowned leader in the automotive and heavy-duty truck industry. This nut plays a role in the functionality and reliability of heavy-duty truck engines. Understanding its purpose, features, and proper maintenance can contribute to the efficient operation of these vehicles.

Basic Concepts

A Gear Retaining Nut is a specialized fastener designed to secure gears within an engine. Its primary function is to hold gears in place, ensuring they remain properly aligned and do not shift during operation. This nut interacts with various engine components, including gear shafts and housings, to maintain the integrity of the gear system 1.

Purpose of the Gear Retaining Nut

The Gear Retaining Nut serves a role in the operation of a truck engine by securing gears and maintaining their alignment. This ensures that the gears mesh correctly, which is important for the transmission of power from the engine to the drivetrain. Proper alignment and secure fastening prevent gear slippage and reduce the risk of mechanical failure, contributing to the overall reliability of the engine 2.

Key Features

The Gear Retaining Nut is characterized by several key features that enhance its performance. It is typically made from high-strength materials such as alloy steel, which provides durability and resistance to wear. The design specifications of the nut, including its thread pitch and size, are tailored to fit specific gear configurations. Additionally, the nut may feature locking mechanisms or serrations to prevent loosening during operation 1.

Benefits

The use of a Gear Retaining Nut offers several advantages. It contributes to improved engine reliability by ensuring gears remain securely in place. This reduces the likelihood of gear slippage and associated mechanical issues. Furthermore, the robust design of the nut can lead to reduced maintenance requirements, as it is less prone to loosening or damage. Enhanced overall performance of the engine is another benefit, as proper gear alignment ensures efficient power transmission 2.

Installation Process

Proper installation of the Gear Retaining Nut is important for its effective function. The process involves several steps:

- Ensure the gear and shaft are clean and free of debris.

- Align the gear correctly on the shaft.

- Position the Gear Retaining Nut over the gear.

- Tighten the nut to the specified torque using a torque wrench to avoid over-tightening, which can damage the gear or shaft.

- Verify the gear alignment and nut tightness after installation.

Common pitfalls to avoid include using excessive force, which can strip the threads, and neglecting to check the alignment post-installation 1.

Troubleshooting and Maintenance

Regular inspection of the Gear Retaining Nut is recommended to identify common issues such as loosening or damage. Signs of wear or corrosion should be addressed promptly to prevent failure. Maintenance procedures include periodic tightening to the specified torque and replacement if the nut shows signs of significant wear or damage. Keeping the nut and surrounding components clean can also contribute to its longevity and performance 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies and services.

Conclusion

Understanding the role, features, and maintenance of the Gear Retaining Nut (Part #3912896) is essential for ensuring the reliability and efficiency of heavy-duty truck engines. Proper installation and regular maintenance of this Cummins part can prevent mechanical issues and contribute to the overall performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.