This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4900776 Hydraulic Pump Gear, manufactured by Cummins, is a critical component in the hydraulic systems of commercial trucks. Understanding its role and significance can enhance the maintenance and performance of these vehicles.

Basic Concepts of Hydraulic Pump Gears

Hydraulic systems in trucks utilize pressurized fluid to transfer power. Hydraulic pump gears convert mechanical energy into hydraulic energy, enabling the operation of various truck components such as brakes, steering systems, and suspension systems 1. These gears mesh together to create a seal that draws fluid into the pump and pressurizes it for use throughout the system.

Purpose of the 4900776 Hydraulic Pump Gear

This Cummins part is designed to facilitate the smooth operation of hydraulic systems in trucks. It ensures that hydraulic fluid is efficiently pressurized and distributed, which is necessary for the proper functioning of hydraulic-operated components. The gear maintains consistent pressure and flow, ensuring that all hydraulic functions operate as intended.

Key Features

The 4900776 Hydraulic Pump Gear is constructed from high-quality materials that resist wear and corrosion, ensuring longevity in demanding environments. Its design incorporates precise engineering specifications to ensure optimal meshing and efficiency. Additionally, the gear is engineered to operate quietly and with minimal maintenance, contributing to overall system reliability.

Benefits

Incorporating this part into a truck’s hydraulic system offers several benefits. It contributes to improved efficiency by ensuring that hydraulic fluid is effectively pressurized and distributed. This results in enhanced performance of hydraulic components, leading to smoother operation of the truck. Furthermore, the gear’s reliable design and construction contribute to the overall reliability of the hydraulic system, reducing the likelihood of unexpected failures.

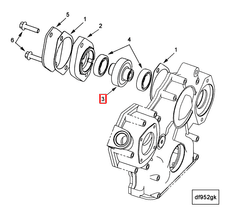

Installation Process

Installing the 4900776 Hydraulic Pump Gear requires careful attention to detail to ensure proper function and longevity. The process involves removing the old gear, cleaning the pump housing, and carefully installing the new gear. It is important to use the correct tools and follow manufacturer guidelines to avoid damage to the gear or surrounding components. Additionally, ensuring that all seals and gaskets are in good condition before installation is crucial for maintaining system integrity.

Common Issues and Troubleshooting

Hydraulic pump gears can encounter issues such as leaks, noise, or inefficient operation. These problems can often be traced back to wear and tear, improper installation, or contamination within the hydraulic system. Troubleshooting these issues involves inspecting the gear and surrounding components for signs of damage or wear, checking fluid levels and quality, and ensuring that the system is free from contaminants. Addressing these issues promptly can help maintain optimal performance and prevent further damage 2.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and efficiency of the 4900776 Hydraulic Pump Gear. This includes routine inspections for signs of wear or damage, ensuring that the hydraulic fluid is clean and at the proper level, and following manufacturer recommendations for fluid changes and system flushes. Additionally, keeping the hydraulic system free from contaminants and performing regular checks on seals and gaskets can contribute to the overall health of the system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding needs of commercial truck operations. Cummins’ commitment to excellence and customer satisfaction has made them a trusted name in the industry.

Compatibility with Cummins Engines

The 4900776 Hydraulic Pump Gear is compatible with several Cummins engines, including the A1400, A1700, A2000, and A2300. This compatibility ensures that the hydraulic systems function without interruption, maintaining the overall efficiency and reliability of the engine.

Role of the 4900776 Hydraulic Pump Gear in Engine Systems

The 4900776 Hydraulic Pump Gear is integral to the efficient operation of various engine systems. When integrated with the drive system, this gear ensures the seamless transfer of mechanical energy, facilitating the operation of hydraulic systems that require precise and consistent power delivery.

In the context of the front gear train accessory, the hydraulic pump gear works in harmony to maintain the synchronization of gear rotations. This synchronization is vital for the accurate distribution of power across different components of the engine. The gear’s design allows it to mesh perfectly with other gears in the train, ensuring minimal energy loss and maximum efficiency.

Furthermore, the hydraulic pump gear’s role extends to enhancing the performance of accessories driven by the front gear train. By providing a stable and reliable power source, it enables these accessories to function optimally, contributing to the overall reliability and performance of the engine system.

Conclusion

The 4900776 Hydraulic Pump Gear is a key component in maintaining the intricate balance and efficiency of engine systems, particularly when coupled with drive mechanisms and front gear train accessories. Regular maintenance and proper installation are essential to ensure the longevity and performance of this critical part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.