This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

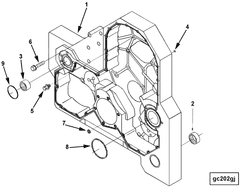

The Cummins 4985108 Gear Housing is a component designed for use in commercial trucks. It serves a specific function within the truck’s transmission system, contributing to the vehicle’s overall operation and efficiency. Understanding its role and significance can provide valuable insights into the maintenance and performance of commercial trucks.

Basic Concepts of Gear Housing

A gear housing is an enclosure that protects the gears within a transmission system. It plays a role in containing lubricants, reducing noise, and shielding internal components from external contaminants. The gear housing contributes to the transmission’s performance and efficiency by ensuring the gears operate smoothly and are well-lubricated 1.

Purpose of the Cummins 4985108 Gear Housing

The Cummins 4985108 Gear Housing is designed to enclose and protect the gears within the transmission of a truck. It plays a role in maintaining the integrity of the transmission system by providing a secure environment for the gears to operate. This housing helps in preserving the alignment and efficiency of the gear system, which is vital for the truck’s performance 2.

Key Features

This Cummins part is constructed from materials that enhance its durability and performance. It incorporates design elements that contribute to its robustness, such as precise engineering to ensure a snug fit and effective sealing. Unique attributes may include specific mounting points or lubrication channels that set it apart from other gear housings 3.

Benefits

The Cummins 4985108 Gear Housing offers several advantages. It provides improved gear protection, which can lead to enhanced transmission efficiency. The housing’s design may also contribute to the longevity and reliability of the truck’s transmission system by reducing wear and tear on the gears 4.

Troubleshooting and Maintenance

Common issues with the Cummins 4985108 Gear Housing may include leaks, wear, or damage to the housing itself. Troubleshooting steps can involve inspecting seals, checking for cracks, and ensuring proper lubrication. Regular maintenance practices, such as cleaning and inspecting the housing for signs of wear, can help ensure optimal performance and longevity 5.

Installation Considerations

When installing the Cummins 4985108 Gear Housing, it is important to consider compatibility with specific truck models. The necessary tools and equipment should be gathered beforehand. Step-by-step installation procedures should be followed to ensure the housing is securely and correctly installed, which is important for the transmission’s operation 6.

Performance Enhancements

The Cummins 4985108 Gear Housing can contribute to overall truck performance. By providing a secure and efficient environment for the gears, it may play a role in potential improvements in fuel efficiency, torque delivery, and drivability. The housing’s design and construction are aimed at enhancing the truck’s transmission system performance 7.

Cummins Overview

Cummins Inc. is a company with a history of providing power solutions, including engines, filtration, and power generation products. In the commercial truck industry, Cummins is known for its range of products that contribute to the performance and efficiency of trucks. The company’s reputation is built on a commitment to quality and innovation in the powertrain sector 8.

Role of Part 4985108 Gear Housing in Engine Systems

The 4985108 Gear Housing is an integral component in the assembly and operation of engine systems, particularly when interfacing with the engine block and cylinder components.

Integration with the Engine Block

The engine block serves as the structural foundation of the engine, housing various critical components including the cylinders, pistons, and crankshaft. The 4985108 Gear Housing is meticulously designed to align with the engine block, ensuring a secure and precise fit. This alignment is essential for maintaining the integrity of the engine’s structural framework. The gear housing’s attachment points are engineered to distribute mechanical stresses evenly across the block, preventing potential weak points that could lead to structural failure over time 9.

Interaction with Cylinder Components

Cylinders are fundamental to the engine’s operation, as they house the pistons that convert fuel energy into mechanical work. The 4985108 Gear Housing plays a supportive role by providing a stable environment for the gears that drive the camshaft, which in turn controls the opening and closing of the valves within the cylinders. This synchronization is vital for the precise timing of fuel injection and exhaust removal, directly influencing the engine’s performance and efficiency.

The gear housing also contributes to the lubrication system by ensuring that oil pathways remain unobstructed, allowing for consistent lubrication of moving parts within the cylinder assembly. This lubrication is key to reducing wear and tear, enhancing the longevity of the engine components 10.

Conclusion

In summary, the Cummins 4985108 Gear Housing is a pivotal component that enhances the functionality and reliability of the engine block and cylinder systems, ensuring smooth operation and prolonged engine life. Its role in protecting and aligning gears within the transmission system is crucial for the overall performance and efficiency of commercial trucks.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Cummins Inc. (n.d.). N14 CM876 N108B, Service Manual (5579823).

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). N14 CM876 N108B, Service Manual (5579823).

↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). N14 CM876 N108B, Service Manual (5579823).

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.