This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

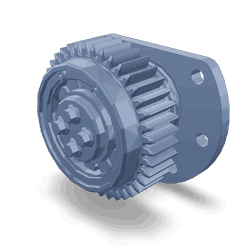

The Cummins 5264301 Idler Gear is a component designed for use in heavy-duty trucks. It serves a specific function within the gear system, contributing to the overall efficiency and performance of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing the operation of heavy-duty trucks.

Basic Concepts of Idler Gears

An idler gear is a type of gear used in mechanical systems to transmit motion between two non-adjacent gears. It does not directly contribute to the power transmission but plays a role in maintaining the proper alignment and spacing between gears. This ensures smooth operation and reduces wear on the gear teeth. Idler gears are commonly used in various mechanical systems to facilitate the transfer of rotational force and to adjust the direction of rotation as needed 1.

Purpose of the 5264301 Idler Gear

The Cummins 5264301 Idler Gear is specifically designed to operate within the gear assembly of heavy-duty trucks. Its role is to maintain the correct mesh between other gears, ensuring efficient power transmission and reducing the likelihood of gear misalignment. By supporting the gear assembly, it contributes to the smooth operation of the truck’s transmission system.

Key Features

The Cummins 5264301 Idler Gear is constructed with a focus on durability and performance. It is made from high-quality materials that resist wear and corrosion, ensuring longevity in demanding environments. The gear features a precise tooth profile that enhances meshing with other gears, promoting efficient power transfer. Additionally, its design includes features that minimize noise and vibration, contributing to a smoother operation 2.

Benefits of Using the 5264301 Idler Gear

Incorporating the Cummins 5264301 Idler Gear into a truck’s gear system offers several advantages. It improves the mesh between gears, leading to more efficient power transmission. This can result in reduced wear on other components and contribute to the overall efficiency of the system. The gear’s design also helps in minimizing noise and vibration, enhancing the driving experience 3.

Installation Considerations

When installing the Cummins 5264301 Idler Gear, it is important to follow guidelines to ensure proper function. This includes aligning the gear correctly within the assembly and adhering to torque specifications to secure it in place. Compatibility with other components should also be verified to ensure seamless integration into the existing gear system.

Troubleshooting Common Issues

Common issues with idler gears may include noise, vibration, and premature wear. These can often be traced back to misalignment, improper installation, or wear and tear. Diagnostic steps may involve inspecting the gear for signs of damage, checking alignment, and ensuring that all components are securely fastened. Solutions may range from realigning the gear to replacing worn components 4.

Maintenance Tips

Regular maintenance of the Cummins 5264301 Idler Gear is key to ensuring its longevity and performance. This includes periodic inspections for signs of wear or damage, adhering to lubrication schedules to reduce friction, and being vigilant for any indications of potential failure. Proper maintenance can help prevent unexpected downtime and extend the life of the gear.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industries. Its product range includes a variety of components and systems designed to enhance the performance and efficiency of vehicles.

Idler Gear Part 5264301 Compatibility with Cummins Engines

The Idler Gear part 5264301 is a critical component designed to work seamlessly with various Cummins engines. This part is engineered to ensure smooth operation and longevity of the engine’s timing system. Below is a detailed look at the compatibility of this idler gear with specific Cummins engine models.

B6.7 Series Engines

The Idler Gear part 5264301 is compatible with the following B6.7 series engines:

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

These engines are known for their robust performance and reliability, often used in heavy-duty applications. The idler gear ensures that the timing components operate correctly, maintaining the engine’s efficiency and reducing the risk of mechanical failure.

ISB/ISD Series Engines

The Idler Gear part 5264301 is also compatible with the following ISB/ISD series engines:

- ISB/ISD 6.7 CM2150 SN

This engine is widely used in various industries, including construction and transportation, due to its durability and power. The idler gear plays a crucial role in the timing mechanism, ensuring that the engine runs smoothly and efficiently.

ISBE Series Engines

The Idler Gear part 5264301 fits the following ISBE series engines:

- ISBE CM2150

- ISBE4 CM850

These engines are designed for high-performance applications, often found in marine and industrial settings. The idler gear is essential for maintaining the precise timing required for these engines to operate at peak performance.

QSB Series Engine

The Idler Gear part 5264301 is compatible with the following QSB series engine:

- QSB7 CM2880 B117

This engine is known for its versatility and is used in various applications, including agricultural and construction equipment. The idler gear ensures that the engine’s timing system functions correctly, contributing to the engine’s overall reliability and performance.

By ensuring that the Idler Gear part 5264301 is correctly installed and maintained, engine operators can expect improved performance, reduced downtime, and extended engine life. This part is a testament to Cummins’ commitment to providing high-quality components that enhance engine reliability and efficiency.

Role of Part 5264301 Idler Gear in Engine Systems

The 5264301 Idler Gear is an essential component in the efficient operation of various engine systems. It is strategically positioned within the housing to facilitate smooth interaction between moving parts.

In the context of the rear gear, the idler gear’s primary function is to maintain proper alignment and tension within the gear train. This ensures that power transmission from the engine to other components is consistent and reliable. By engaging with both the driving and driven gears, the idler gear helps to reduce wear and tear on these components, thereby enhancing the overall durability of the engine system.

Additionally, the idler gear plays a significant role in noise reduction. Its precise placement and design help to absorb vibrations that occur during operation, leading to a quieter and more efficient engine performance. This is particularly important in high-performance engines where maintaining optimal conditions is key to achieving peak efficiency.

Furthermore, the idler gear contributes to the synchronization of various engine components. By ensuring that gears mesh correctly, it helps to prevent slippage and ensures that power is transmitted smoothly throughout the system. This is vital for maintaining the engine’s performance under varying loads and conditions.

Conclusion

In summary, the 5264301 Idler Gear is a key element in the intricate dance of engine components, working seamlessly within the housing and in conjunction with the rear gear to ensure reliable and efficient engine operation. Proper installation, maintenance, and understanding of its role are crucial for maximizing the performance and longevity of heavy-duty truck engines.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Pulkrabek, W.W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.