This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4099892 Mechanical Governor is a component designed to regulate the speed of heavy-duty truck engines. Its purpose is to ensure that the engine operates within specified speed limits under varying load conditions, contributing to the overall efficiency and performance of the vehicle. This governor is significant in maintaining the balance between engine power and fuel consumption, which is vital for the optimal operation of heavy-duty trucks 1.

Basic Concepts of Mechanical Governors

A mechanical governor is a device that automatically controls the speed of an engine by regulating the fuel supply. It operates on the principles of centrifugal force and feedback mechanisms. As the engine speed increases, the governor uses centrifugal force to adjust the fuel supply, thereby controlling the engine’s speed. This feedback loop ensures that the engine maintains a consistent speed regardless of the load it is carrying 2.

Purpose and Role in Truck Operation

The Cummins 4099892 Mechanical Governor plays a specific role in the operation of a truck by helping to maintain engine speed and performance under varying load conditions. It ensures that the engine does not exceed its maximum speed, which could lead to inefficient operation or damage. By regulating the fuel supply in response to changes in engine speed, the governor helps to optimize fuel efficiency and engine performance 3.

Key Features

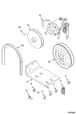

The Cummins 4099892 Mechanical Governor is characterized by its robust design and precise components. It includes a flyweight mechanism, a linkage system, and a throttle control that work together to regulate engine speed. These features contribute to the governor’s function and reliability, ensuring that it can withstand the demanding conditions of heavy-duty truck operation.

Benefits of Using a Mechanical Governor

Incorporating a mechanical governor into a truck’s engine system offers several advantages. It improves fuel efficiency by ensuring that the engine operates at optimal speeds. It also enhances engine performance by maintaining consistent speed under varying loads, which can reduce wear on engine components. Additionally, the use of a mechanical governor can lead to more reliable engine operation and longer engine life.

Troubleshooting and Maintenance

Common issues with the Cummins 4099892 Mechanical Governor may include inconsistent engine speed, difficulty starting the engine, or poor fuel efficiency. Diagnostic steps involve checking the governor’s components for wear or damage, ensuring proper linkage adjustment, and verifying that the flyweights are functioning correctly. Regular maintenance practices, such as cleaning and lubricating moving parts, can help ensure optimal performance and longevity of the governor.

Integration with Cummins Engines

The Cummins 4099892 Mechanical Governor is designed to work seamlessly with Cummins engines. It incorporates specific compatibility features and design considerations that ensure it functions effectively within the engine system. This integration allows for precise control of engine speed and fuel supply, contributing to the overall performance and reliability of Cummins-powered trucks.

Historical Context and Evolution

The evolution of mechanical governors in the automotive industry has seen significant advancements, with Cummins playing a notable role in these innovations. Early mechanical governors were simple devices, but over time, they have become more sophisticated, incorporating advanced design features and materials to improve performance and reliability. Cummins has been at the forefront of these developments, continually enhancing the design and functionality of its mechanical governors.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong commitment to innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s focus on developing reliable and efficient engine components, including mechanical governors, underscores its dedication to enhancing the performance and durability of heavy-duty trucks.

Application in G5.9 Engines

In the G5.9 engine series, the Mechanical Governor part 4099892 ensures that the engine operates within its optimal speed range. This is achieved by precisely controlling the fuel input, which directly impacts the engine’s performance and longevity. The governor’s ability to modulate fuel delivery helps in maintaining consistent engine speed, even under varying load conditions.

Grouping of Engines

The Mechanical Governor part 4099892 is compatible with a range of Cummins engines, including but not limited to, the G5.9 series. This part is designed to fit seamlessly into these engines, providing a reliable and efficient means of speed regulation. The governor’s design ensures that it can handle the specific demands of each engine type, contributing to the overall performance and durability of the engine.

Importance of the Mechanical Governor

The Mechanical Governor part 4099892 is integral to the engine’s operation, as it directly influences the engine’s performance metrics such as speed, power output, and fuel efficiency. By maintaining a stable engine speed, the governor helps in reducing wear and tear on engine components, thereby extending the engine’s lifespan. Additionally, it ensures that the engine operates within safe parameters, preventing potential damage from over-revving or under-performing.

Installation and Maintenance

Proper installation of the Mechanical Governor part 4099892 is crucial to ensure its effectiveness. Technicians should follow the manufacturer’s guidelines for installation, which typically include precise alignment and secure mounting. Regular maintenance checks are also recommended to ensure that the governor remains in optimal condition, free from wear and obstructions that could affect its performance.

Interaction with the Fuel Governor

The Mechanical Governor, identified by part number 4099892, works in tandem with the fuel governor to maintain consistent engine speed under varying load conditions. The fuel governor adjusts the fuel supply to the engine based on the demand, while the Mechanical Governor senses the engine’s rotational speed and modulates the fuel governor’s operation accordingly. This dynamic interaction ensures that the engine operates within its optimal performance range, providing the necessary power while conserving fuel and reducing wear on engine components.

Integration within the Engine Arrangement

In the broader context of the engine arrangement, the Mechanical Governor is positioned to receive direct feedback from the engine’s crankshaft or flywheel. This feedback loop allows the governor to make real-time adjustments to the fuel delivery, ensuring that the engine maintains a steady speed regardless of external factors such as load changes or environmental conditions. The governor’s ability to fine-tune the fuel supply in response to engine speed variations is essential for the smooth operation of the engine, contributing to overall efficiency and reliability.

Conclusion

The Cummins 4099892 Mechanical Governor is a key component in the engine’s fuel delivery and speed control system, working closely with the fuel governor and integrating seamlessly within the engine’s overall arrangement to ensure optimal performance, efficiency, and protection. Its role in maintaining engine speed, enhancing fuel efficiency, and protecting the engine from overspeed conditions makes it a valuable asset in any engine system.

-

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition, Delmar Cengage Learning, 2011.

↩ -

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.