This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

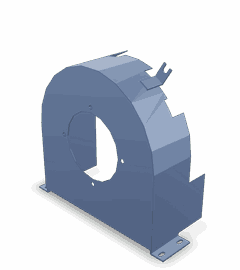

The Damper Guard (Part #3001952) by Cummins is designed to enhance the operation of commercial trucks by protecting engine components from torsional vibrations. This part is essential for maintaining engine efficiency and reliability under various operating conditions 1.

Purpose and Function

The Damper Guard’s primary role is to absorb and dampen torsional vibrations that occur during engine operation. These vibrations can lead to wear and tear on critical parts. By managing these vibrations, the Damper Guard helps maintain the integrity of the engine system, contributing to smoother operation and potentially extending the lifespan of associated components 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the harsh conditions typical of commercial truck operations. The part’s construction includes durable materials that offer resistance to wear and environmental factors, ensuring long-term performance. Additionally, its design incorporates features that enhance its ability to effectively manage vibrations, contributing to the overall stability of the engine system 3.

Benefits

Incorporating the Damper Guard into a truck’s engine system offers several advantages. It contributes to improved engine longevity by reducing the stress on engine components caused by vibrations. This can lead to reduced maintenance needs, as the protective function of the Damper Guard helps prevent premature wear. Furthermore, by ensuring the engine operates smoothly, the Damper Guard can enhance the overall performance of the truck, leading to more efficient operations 4.

Installation Process

Installing the Damper Guard requires careful attention to ensure it functions correctly. The process involves securing the part in its designated position within the engine system. Tools required may include wrenches and possibly a torque wrench to ensure proper tightening. It is important to follow manufacturer guidelines during installation to avoid damaging the part or other engine components. Proper alignment and secure fastening are critical to the Damper Guard’s effectiveness 5.

Common Issues and Troubleshooting

While the Damper Guard is designed for durability, issues may arise over time. Common problems include wear or damage to the part, which can affect its ability to dampen vibrations effectively. Troubleshooting steps may involve inspecting the Damper Guard for signs of wear, ensuring it is properly installed, and replacing it if necessary. Regular checks can help identify issues early, allowing for timely maintenance or replacement.

Maintenance Tips

To ensure the Damper Guard continues to function effectively, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the part as part of routine engine maintenance can also help maintain its performance. Following manufacturer guidelines for inspection intervals and maintenance procedures will help ensure the Damper Guard remains in optimal condition.

Compatibility and Usage

The Damper Guard is designed for specific types of engines and trucks, with guidelines provided by Cummins for its use. It is important to consult these guidelines to ensure compatibility with the specific engine and truck model in question. Adhering to usage recommendations can help maximize the benefits of the Damper Guard, ensuring it contributes effectively to the engine’s performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial transportation, demonstrating a commitment to enhancing the performance and reliability of truck engines.

Cummins Damper Guard 3001952 Compatibility

The Cummins Damper Guard part number 3001952 is designed to fit seamlessly with several engine models, ensuring optimal performance and protection. This part is integral to the engine’s operational integrity, providing a protective barrier for the damper mechanism.

N14 MECHANICAL Engines

For the N14 MECHANICAL engines, the Damper Guard 3001952 is a critical component. It is engineered to fit precisely, safeguarding the damper from potential damage caused by debris or excessive wear. This ensures that the damper operates smoothly, contributing to the engine’s overall efficiency and longevity.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the installation of the Cummins Damper Guard 3001952. This part is designed to integrate perfectly with the NH/NT 855 series, providing essential protection for the damper. By doing so, it helps maintain the engine’s performance and reliability, ensuring that the damper functions as intended without obstruction or damage.

Installation and Maintenance

Proper installation of the Damper Guard 3001952 is crucial for its effectiveness. Technicians should follow the manufacturer’s guidelines to ensure that the part is securely attached and aligned correctly. Regular maintenance checks should be conducted to verify that the guard remains in good condition and continues to provide the necessary protection for the damper.

Understanding the Integration of Part 3001952 Damper Guard in Engine Systems

The Damper Guard is an essential component in the protection and efficient operation of various engine systems. Its primary function is to safeguard the damper and associated components from external elements and potential damage.

Belt and Damper Guard Interaction

When installed, the Damper Guard works in conjunction with the belt system. It provides a protective enclosure around the damper, ensuring that the belt remains in optimal condition. This interaction is vital for maintaining the integrity of the belt, which is responsible for transferring power from the engine to other components such as the alternator, water pump, and air conditioning compressor.

Belt Guard and Damper Guard Relationship

Similarly, the Damper Guard complements the belt guard by offering an additional layer of security. This dual-guard system enhances the overall protection of the belt and damper, reducing the likelihood of belt slippage or damage due to debris or excessive vibration.

Damper Guard and Damper Shield Synergy

The Damper Guard often operates in tandem with a damper shield. While the shield provides a barrier against heat and direct impact, the Damper Guard offers comprehensive coverage against a broader range of threats, including environmental factors and mechanical wear.

Guard and Front Engine Component Protection

In the front engine compartment, the Damper Guard plays a significant role in protecting not only the damper but also adjacent components. By preventing debris from contacting sensitive parts, it contributes to the longevity and reliability of the entire engine system.

Comprehensive Engine System Integration

Overall, the Damper Guard is a key component in the engine’s protective architecture. Its integration with the belt, damper, and other guards ensures a cohesive defense mechanism that enhances the engine’s performance and durability. Engineers and mechanics should consider the Damper Guard as an integral part of the engine’s protective strategy, working alongside other components to maintain optimal engine health.

Conclusion

The Damper Guard (Part #3001952) by Cummins plays a vital role in protecting engine components from torsional vibrations, ensuring smoother operation and potentially extending the lifespan of associated components. Its robust design and high-quality materials make it suitable for the harsh conditions of commercial truck operations. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, contributing to the overall efficiency and reliability of truck engines.

-

Daniel Williams, Generalized Vehicle Dynamics, SAE International, 2022.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak, Critical Component Wear in Heavy Duty Engines, John Wiley & Sons, 2011.

↩ -

Andrew Livesey, The Repair of Vehicle Bodies, Elevier, 2000.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak, The Automotive Transmission Book Powertrain, Springer, 2015.

↩ -

Cummins Inc., Operation and Maintenance Manual, Bulletin Number 4367450, QSK60 CM2350 K117.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.