This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

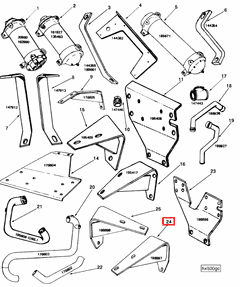

The Heat Exchanger Bracket (Part #198897) manufactured by Cummins is a component designed to support the heat exchanger within a truck’s cooling system. This Cummins part plays a role in maintaining the optimal performance of the engine by ensuring the heat exchanger is securely positioned and functions efficiently 1.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting structure for the heat exchanger. Its primary function is to support the heat exchanger, allowing it to operate within the cooling system without shifting or becoming misaligned. This support contributes to the overall efficiency of the truck’s cooling system by maintaining the proper position and alignment of the heat exchanger 2.

Purpose of the Heat Exchanger Bracket

The Heat Exchanger Bracket plays a role in the operation of a truck by securing the heat exchanger in place. This ensures that the heat exchanger remains properly aligned and functions as intended. By maintaining the heat exchanger’s position, the bracket helps facilitate the efficient transfer of heat away from the engine, contributing to the cooling system’s effectiveness 3.

Key Features

The Cummins Heat Exchanger Bracket is constructed from materials chosen for their durability and resistance to the harsh conditions found in a truck’s engine compartment. Its design includes elements that enhance both durability and performance, such as reinforced mounting points and corrosion-resistant coatings. These features contribute to the bracket’s ability to withstand the rigors of heavy-duty use, ensuring long-term reliability.

Benefits

Using the Cummins Heat Exchanger Bracket offers several advantages. It provides improved stability for the heat exchanger, which can lead to enhanced cooling efficiency. This, in turn, may contribute to extended engine life and reliability by ensuring the engine operates within its optimal temperature range. The bracket’s design and material composition are tailored to meet the demands of heavy-duty applications, offering a robust solution for truck cooling systems.

Installation and Compatibility

Proper installation of the Heat Exchanger Bracket involves several steps to ensure it is correctly positioned and secured. This process may require specific tools and preparatory steps to align the bracket with the truck’s existing cooling system components. Ensuring compatibility with the truck model and heat exchanger type is crucial for the bracket to function effectively.

Troubleshooting and Maintenance

Common issues with the Heat Exchanger Bracket, such as misalignment or damage, can be addressed through regular inspections and maintenance. Checking for signs of wear or corrosion and ensuring all mounting points are secure can help maintain the bracket’s effectiveness. Regular maintenance not only ensures the longevity of the bracket but also contributes to the overall efficiency of the truck’s cooling system.

Cummins Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and commitment to quality. The company’s expertise in engine technology extends to the components that support engine performance, including the cooling system. Cummins’ dedication to producing reliable and efficient parts is evident in the design and functionality of the Heat Exchanger Bracket.

Conclusion

The Heat Exchanger Bracket (Part #198897) is a vital component in Cummins engines, ensuring the heat exchanger is securely positioned and functions efficiently. Its robust construction and design contribute to the overall efficiency and reliability of the truck’s cooling system, ultimately supporting optimal engine performance.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.