This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

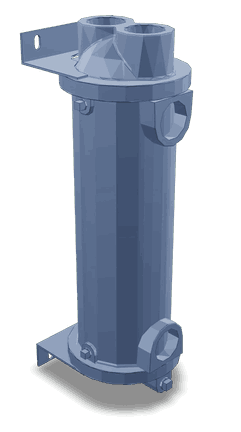

The Cummins 3396492 Heat Exchanger is a critical component in commercial truck operations, designed to facilitate the transfer of heat between fluids without mixing them. This process is essential for maintaining optimal operating temperatures within the truck’s engine and other systems, contributing to the efficiency and reliability of truck operations 1.

Basic Concepts of Heat Exchangers

A heat exchanger is a system that transfers heat between two or more fluids at different temperatures. It operates on the principle of thermal conduction, where heat moves from a hotter fluid to a cooler one through a solid barrier. In truck systems, heat exchangers regulate temperatures to enhance performance and protect components from thermal stress 2.

Role of the 3396492 Heat Exchanger in Truck Operation

The 3396492 Heat Exchanger is integral to the operation of a commercial truck by managing the temperature of various fluids within the engine system. It interacts with the engine’s cooling system, transmission, and other components that require temperature regulation. By maintaining optimal temperatures, it contributes to the overall efficiency and longevity of the truck’s engine and associated systems 3.

Key Features of the 3396492 Heat Exchanger

The 3396492 Heat Exchanger is characterized by its robust design and the materials used in its construction. It is built to withstand the demanding conditions of commercial truck operations. Features such as corrosion-resistant materials and a compact design enhance its performance and durability. Additionally, its design allows for efficient heat transfer, which is crucial for the effective operation of the truck’s systems 4.

Benefits of Using the 3396492 Heat Exchanger

Incorporating the 3396492 Heat Exchanger into a truck’s system offers several advantages. It contributes to improved engine efficiency by ensuring that the engine operates within its optimal temperature range. This can lead to better fuel economy and reduced emissions. Furthermore, the reliability and performance enhancements provided by this heat exchanger can result in fewer breakdowns and lower maintenance costs over the truck’s lifespan 5.

Installation and Integration

Proper installation and integration of the 3396492 Heat Exchanger are vital for ensuring its optimal functionality and compatibility with the truck’s system. It should be installed according to the manufacturer’s guidelines to ensure that it operates efficiently and effectively. Compatibility with the truck’s existing systems is also important to avoid any issues with performance or reliability 6.

Maintenance and Care

Routine maintenance and care practices are recommended to ensure the longevity and efficiency of the 3396492 Heat Exchanger. This includes regular cleaning to remove any buildup that could impede heat transfer, inspection for signs of wear or damage, and adherence to replacement schedules as recommended by the manufacturer. Proper maintenance can help prevent issues and ensure the heat exchanger continues to perform at its best 7.

Troubleshooting Common Issues

Common problems associated with the 3396492 Heat Exchanger may include reduced efficiency due to buildup or damage. Troubleshooting steps may involve cleaning the heat exchanger, inspecting for leaks or damage, and ensuring that it is properly integrated into the truck’s system. Addressing these issues promptly can help maintain the performance and reliability of the heat exchanger 8.

Performance Optimization

To maximize the performance of the 3396492 Heat Exchanger, it is important to follow best practices for operation and maintenance. This may include regular inspections, cleaning, and adjustments as necessary. Additionally, staying informed about any upgrades or improvements that may enhance the heat exchanger’s performance can contribute to the overall efficiency and reliability of the truck’s system 9.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to advancing technology and providing reliable products has made it a preferred choice for commercial truck operators worldwide 10.

Conclusion

The Cummins 3396492 Heat Exchanger plays a vital role in the thermal management of commercial trucks, contributing to engine efficiency, performance, and longevity. Its robust design, efficient heat transfer capabilities, and compatibility with various engine systems make it an essential component for truck operators. Proper installation, maintenance, and care are crucial for ensuring the optimal performance and reliability of this heat exchanger.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training, Second Edition. Routledge.

↩ -

General Information, Bulletin Number 3666112, Operation and Maintenance Manual.

↩ -

Ibid.

↩ -

Ibid.

↩ -

Ibid.

↩ -

Ibid.

↩ -

Ibid.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.