This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

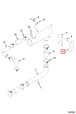

The Cummins Heat Exchanger Bracket, part number 3897086, is a critical component designed for heavy-duty truck operations. Manufactured by Cummins, a renowned name in the industry, this bracket is engineered to enhance the efficiency and reliability of truck cooling systems. Understanding its role and functionality is essential for maintaining optimal engine performance in demanding environments.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting component for heat exchangers within a truck’s cooling system. Its primary function is to secure the heat exchanger in place, ensuring efficient operation by facilitating heat transfer between fluids without mixing them. This bracket interfaces with various components, including the heat exchanger itself, the truck’s frame, and other cooling system elements, to maintain stability and alignment 1.

Purpose of the Cummins Heat Exchanger Bracket

The Cummins Heat Exchanger Bracket, part number 3897086, plays a specific role in the operation of a truck by securely holding the heat exchanger in the cooling system. This ensures that the heat exchanger can effectively transfer heat away from the engine, contributing to efficient engine performance. By maintaining the heat exchanger in the correct position, the bracket helps to prevent overheating, which can lead to engine damage and reduced efficiency 2.

Key Features

This Cummins part is constructed from durable materials, designed to withstand the rigors of heavy-duty truck operations. Its design includes features that enhance its performance and durability, such as corrosion-resistant coatings and precise engineering to ensure a secure fit. These attributes contribute to the bracket’s ability to support the heat exchanger effectively under various operating conditions 3.

Benefits

The advantages provided by the Cummins Heat Exchanger Bracket include improved cooling efficiency, which is crucial for maintaining engine performance. Its durable construction enhances the longevity of the cooling system components, potentially contributing to overall engine longevity. The bracket’s design also ensures that the heat exchanger remains securely in place, reducing the risk of damage or malfunction 4.

Installation Process

Installing the Cummins Heat Exchanger Bracket requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include ensuring the truck’s cooling system is clean and free of debris. The installation process involves securing the bracket to the truck’s frame and attaching the heat exchanger. Tools required may include wrenches and possibly a torque wrench to ensure bolts are tightened to the manufacturer’s specifications. Following best practices during installation helps to ensure the bracket functions as intended.

Troubleshooting Common Issues

Common problems associated with heat exchanger brackets can include misalignment, corrosion, or damage from physical impact. Potential causes of these issues may be improper installation, exposure to harsh environmental conditions, or wear over time. Recommended troubleshooting steps include inspecting the bracket for signs of damage or corrosion, ensuring it is properly aligned and secured, and addressing any issues promptly to prevent further damage to the cooling system.

Maintenance Tips

To ensure optimal performance of the Cummins Heat Exchanger Bracket, regular inspection practices are recommended. This includes checking for signs of wear, corrosion, or damage. Cleaning the bracket and surrounding areas can help prevent buildup that may affect performance. Knowing when to consider replacement is also important; if the bracket shows significant wear or damage, it should be replaced to maintain the efficiency of the cooling system.

Cummins: A Brief Overview

Cummins Inc. is a leader in the heavy-duty truck industry, known for its wide range of products and commitment to quality and reliability. The company’s history of innovation and excellence provides context for the quality and reliability of the Cummins Heat Exchanger Bracket. Cummins’ reputation in the industry underscores the trust and confidence in their products among professionals and enthusiasts alike.

Compatibility with Cummins Engines

The Cummins Heat Exchanger Bracket part number 3897086 is designed to be compatible with several engine models, ensuring a secure and efficient mounting of the heat exchanger within the engine compartment. This bracket is integral to the proper functioning of the engine’s cooling system, providing a stable platform for the heat exchanger to operate effectively.

For the 4B3.9 engine, the 3897086 bracket is engineered to fit seamlessly, allowing for optimal heat dissipation and maintaining the engine’s operational temperature. Its design ensures that the heat exchanger is positioned correctly, which is crucial for the engine’s overall performance and longevity.

Similarly, the 6B5.9 engine also benefits from the use of the 3897086 Heat Exchanger Bracket. This bracket is specifically tailored to the 6B5.9’s unique design and requirements, ensuring that the heat exchanger is securely mounted and aligned. This alignment is vital for the efficient transfer of heat away from the engine, preventing overheating and potential damage.

Both engines, despite their different configurations, rely on the 3897086 bracket to maintain the integrity of their cooling systems. The bracket’s robust construction and precise fit are essential for the reliable operation of these engines, contributing to their overall efficiency and durability.

Role of the Cummins Heat Exchanger Bracket in Engine Systems

The Cummins Heat Exchanger Bracket, identified by part number 3897086, is an integral component in the assembly and functionality of engine systems. This bracket securely mounts the heat exchanger to the engine, ensuring stability and proper alignment.

When installed, the bracket allows for efficient heat transfer between the engine’s cooling system and the heat exchanger. This process is essential for maintaining optimal engine temperature, which directly impacts performance and longevity.

Additionally, the bracket facilitates the connection of various hoses and pipes that transport coolant between the engine and the heat exchanger. This ensures a leak-free system, preventing coolant loss and maintaining pressure within the cooling circuit.

The Cummins Heat Exchanger Bracket also plays a role in vibration damping. By providing a sturdy mount, it reduces the transmission of engine vibrations to the heat exchanger, which can otherwise lead to component fatigue and failure over time.

In summary, the proper installation and function of the Cummins Heat Exchanger Bracket are essential for the reliable operation of the engine’s cooling system, contributing to overall engine efficiency and durability.

Conclusion

The Cummins Heat Exchanger Bracket, part number 3897086, is a vital component in the maintenance and efficiency of heavy-duty truck engines. Its role in securing the heat exchanger, facilitating efficient heat transfer, and ensuring system stability is crucial for optimal engine performance. Regular maintenance and proper installation are key to leveraging the full benefits of this part, ensuring the longevity and reliability of the engine’s cooling system.

-

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Maclaurin, Bruce. High Speed Off-Road Vehicles. Wiley, 2018.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.