This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3910582 Heat Exchanger is a component designed for use in commercial truck operations. Its purpose is to facilitate the transfer of heat between two or more fluids without mixing them, playing a significant role in maintaining optimal operating temperatures within the truck’s engine system.

Basic Concepts of Heat Exchangers

Heat exchangers are devices built for efficient heat transfer from one medium to another. They are integral to various systems, including refrigeration, air conditioning, and engine cooling systems in heavy-duty trucks. The principle behind their operation involves the exchange of thermal energy between two fluids at different temperatures, which can be achieved through conduction, convection, and radiation. In the context of heavy-duty trucks, heat exchangers help regulate engine temperature, ensuring efficient operation and longevity of the engine components 1.

Purpose of the Cummins 3910582 Heat Exchanger

The Cummins 3910582 Heat Exchanger serves a specific function within the operation of a truck. It is primarily involved in the engine cooling system, where it helps manage the temperature of the engine coolant. By transferring excess heat from the coolant to the surrounding air, it plays a role in maintaining the engine within its optimal operating temperature range. Additionally, this heat exchanger may have applications beyond engine cooling, such as in the heating of cabin air or in other systems where heat management is crucial.

Key Features

The Cummins 3910582 Heat Exchanger is characterized by several key features that enhance its performance and durability. Its design is engineered to maximize heat transfer efficiency while minimizing the space it occupies. The materials used in its construction are selected for their thermal conductivity, corrosion resistance, and durability under the demanding conditions of commercial truck operations. Efficiency is a hallmark of this heat exchanger, with its design allowing for significant heat transfer with minimal pressure drop. Unique attributes may include advanced fin technology for increased surface area and improved heat exchange capabilities 2.

Benefits

The advantages provided by the Cummins 3910582 Heat Exchanger include improved engine performance through effective temperature management. Enhanced durability is another benefit, as the heat exchanger is built to withstand the rigors of commercial truck use. Fleet operators may also experience potential cost savings due to the heat exchanger’s efficiency and longevity, reducing the need for frequent replacements or repairs.

Installation and Integration

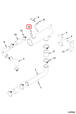

Proper installation of the Cummins 3910582 Heat Exchanger is crucial for its effective operation. Guidelines for installation include ensuring compatibility with the truck’s existing systems and following manufacturer recommendations for mounting and connection. Integration with the engine cooling system requires careful attention to detail to ensure that all connections are secure and that the heat exchanger is properly aligned within the airflow path.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the Cummins 3910582 Heat Exchanger. This includes periodic inspection for signs of corrosion, leaks, or blockages within the heat exchanger. Common issues may involve reduced efficiency due to fouling or damage to the fins. Diagnostic tips and troubleshooting steps can help identify and address these issues, ensuring the heat exchanger continues to operate effectively.

Performance and Efficiency

The Cummins 3910582 Heat Exchanger contributes to the overall performance and efficiency of the truck by ensuring optimal engine temperature. This can lead to improved fuel economy as the engine operates more efficiently within its designed temperature range. Effective thermal management also plays a role in reducing stress on engine components, potentially leading to longer engine life 3.

Environmental Impact

The use of the Cummins 3910582 Heat Exchanger can have positive environmental impacts. By improving the efficiency of the engine cooling system, it contributes to reduced emissions and improved fuel efficiency. These factors are important in minimizing the environmental footprint of commercial truck operations.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications.

Compatibility with Engine Models

The Cummins Heat Exchanger part number 3910582 is designed to integrate seamlessly with various engine models, ensuring efficient heat management and optimal performance. This heat exchanger is engineered to fit within the cooling systems of specific Cummins engines, enhancing their operational efficiency.

4B3.9 Engine Series

The 4B3.9 engine series benefits significantly from the integration of the 3910582 heat exchanger. This part is specifically tailored to fit within the engine’s cooling architecture, providing effective heat dissipation and maintaining the engine’s optimal operating temperature. The design ensures that the heat exchanger complements the engine’s overall cooling system, contributing to its longevity and reliability.

4BT3.9 Engine Series

Similarly, the 4BT3.9 engine series is another beneficiary of the 3910582 heat exchanger. This part is engineered to integrate smoothly with the engine’s cooling system, ensuring that heat is managed efficiently. The heat exchanger’s design allows it to fit precisely within the engine’s cooling pathways, enhancing the engine’s performance and durability.

6BT5.9 Engine Series

The 6BT5.9 engine series also incorporates the 3910582 heat exchanger as part of its cooling system. This heat exchanger is designed to fit seamlessly within the engine’s cooling architecture, ensuring that heat is dissipated effectively. The integration of this part helps maintain the engine’s optimal operating temperature, contributing to its overall efficiency and longevity.

6CTA8.3 Engine Series

The 6CTA8.3 engine series is another model that utilizes the 3910582 heat exchanger. This part is engineered to fit within the engine’s cooling system, ensuring that heat is managed efficiently. The heat exchanger’s design allows it to integrate smoothly with the engine’s cooling pathways, enhancing the engine’s performance and durability.

12N1400 Engine Series

The 12N1400 engine series also incorporates the 3910582 heat exchanger as part of its cooling system. This part is designed to fit precisely within the engine’s cooling architecture, ensuring that heat is dissipated effectively. The integration of this heat exchanger helps maintain the engine’s optimal operating temperature, contributing to its overall efficiency and longevity.

Role of Part 3910582 Heat Exchanger in Engine Systems

The heat exchanger, specifically part 3910582, is integral to the efficient operation of various engine systems. It facilitates the transfer of thermal energy between two or more fluids without them coming into direct contact. This process is essential for maintaining optimal operating temperatures and enhancing the overall performance of the engine.

In the cooling system, the heat exchanger works in conjunction with the radiator, coolant, and water pump. It helps dissipate excess heat generated by the engine, preventing overheating and ensuring that the engine operates within its specified temperature range. The coolant absorbs heat from the engine block and cylinder heads, and as it passes through the heat exchanger, this heat is transferred to the ambient air, cooling the coolant before it recirculates back into the engine.

Within the exhaust system, the heat exchanger plays a role in the turbocharger. As exhaust gases flow through the turbine, they generate significant heat. The heat exchanger helps manage this heat, ensuring that it does not adversely affect other components. It also aids in preheating the intake air, which can improve combustion efficiency and overall engine performance.

In the lubrication system, the heat exchanger assists in maintaining the viscosity of the engine oil. As the oil circulates through the engine, it absorbs heat from various components. The heat exchanger helps cool the oil, ensuring it remains within the optimal temperature range for effective lubrication and reduced wear on engine parts.

Additionally, in the air intake system, the heat exchanger can be part of an intercooler in turbocharged engines. It cools the compressed air from the turbocharger before it enters the combustion chamber. This reduces the air temperature, increasing its density and allowing for more efficient combustion and higher power output.

Overall, the heat exchanger, part 3910582, is a versatile component that enhances the efficiency and reliability of multiple engine systems by effectively managing thermal energy.

Conclusion

The Cummins 3910582 Heat Exchanger is a critical component in the operation of commercial trucks, ensuring optimal engine temperature and efficiency. Its design and features contribute to improved engine performance, durability, and environmental impact. Proper installation, maintenance, and understanding of its role in various engine systems are essential for maximizing its benefits.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Hilgers, M. (2023). Entire Vehicle: Second Edition. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.