This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3968810 Heat Exchanger is a component designed for use in commercial truck operations. It plays a role in maintaining the optimal operating temperature of the engine by facilitating the transfer of heat between fluids. This ensures that the engine operates within its designed temperature range, which is important for efficiency, performance, and longevity.

Basic Concepts of Heat Exchangers

A heat exchanger is a system used to transfer heat between two or more fluids at different temperatures. It operates on the principle of thermal conduction, where heat moves from a hotter fluid to a cooler one through a solid barrier. This process allows for efficient temperature regulation without mixing the fluids. Heat exchangers are integral in various applications, including engine cooling systems, where they help manage the temperature of the engine coolant 1.

Purpose of the Cummins 3968810 Heat Exchanger

The Cummins 3968810 Heat Exchanger is specifically designed to play a role in the engine cooling system of commercial trucks. It facilitates the transfer of heat from the engine coolant to the ambient air, ensuring that the engine does not overheat. Additionally, it may be used in other systems where temperature regulation is necessary, such as in the transmission or hydraulic systems of heavy-duty trucks.

Key Features

The Cummins 3968810 Heat Exchanger is characterized by several design elements and materials that enhance its performance. It is constructed using high-quality materials that are resistant to corrosion and wear, ensuring durability in harsh operating conditions. The design includes efficient fin spacing and core construction that maximizes heat transfer while minimizing pressure drop. These features contribute to the overall effectiveness and reliability of the heat exchanger 2.

Benefits

The advantages of using the Cummins 3968810 Heat Exchanger include improved engine efficiency, enhanced reliability, and potential cost savings for fleet operators. By maintaining optimal engine temperatures, it helps to ensure that the engine operates at peak efficiency, which can lead to fuel savings and reduced emissions. Additionally, the durability and reliability of the heat exchanger can reduce maintenance costs and downtime for commercial fleets.

Installation and Integration

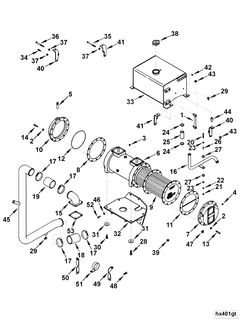

Proper installation and integration of the Cummins 3968810 Heat Exchanger within a truck’s system are important for ensuring optimal performance. This involves following manufacturer guidelines for mounting, connecting hoses, and ensuring proper alignment within the engine compartment. It is also important to consider the compatibility with the existing cooling system components to ensure seamless integration.

Performance and Efficiency

The Cummins 3968810 Heat Exchanger contributes to the overall performance and efficiency of the truck by effectively managing engine temperatures. This can lead to improved fuel economy, reduced emissions, and extended engine life. Comparative data may show that trucks equipped with this heat exchanger operate more efficiently under various conditions, highlighting its value in commercial truck operations 3.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the longevity and optimal performance of the Cummins 3968810 Heat Exchanger. Common issues may include clogging, leaks, or reduced efficiency, which can often be addressed through cleaning, inspection, and repair. Following manufacturer guidelines for maintenance intervals and procedures can help prevent issues and ensure continued reliable operation.

Common Challenges and Solutions

Typical challenges that may arise with the Cummins 3968810 Heat Exchanger include contamination, corrosion, and mechanical damage. Solutions or workarounds may involve regular cleaning to remove contaminants, applying protective coatings to prevent corrosion, and inspecting for physical damage during routine maintenance checks. Addressing these challenges promptly can help maintain the efficiency and reliability of the heat exchanger.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Their product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Heat Exchanger 3968810 Compatibility

The Cummins Heat Exchanger part number 3968810 is designed to integrate seamlessly with various engine models, ensuring optimal performance and efficiency. This heat exchanger is engineered to manage the thermal dynamics of the engine, playing a role in maintaining the desired operating temperatures.

K19 Engine Series

The K19 engine series benefits significantly from the installation of the 3968810 heat exchanger. This part is specifically tailored to fit within the thermal management system of the K19 engines, enhancing their overall performance. The heat exchanger’s design allows it to efficiently transfer heat, reducing the risk of overheating and ensuring that the engine operates within its optimal temperature range.

Integration and Functionality

The integration of the 3968810 heat exchanger into the K19 engine series involves precise placement within the engine’s cooling system. This ensures that it can effectively dissipate heat from the engine’s components, maintaining a stable internal environment. The heat exchanger’s robust construction and high-quality materials guarantee durability and longevity, making it a reliable component for the K19 engines.

Performance Enhancement

By incorporating the 3968810 heat exchanger into the K19 engines, users can expect improved thermal efficiency and enhanced engine performance. The heat exchanger’s ability to manage heat effectively contributes to better fuel economy and reduced wear on engine components, extending the lifespan of the engine. This makes it an important part for maintaining the reliability and efficiency of the K19 engines.

Role of Heat Exchanger Part 3968810 in Engine Systems

In engine systems, the heat exchanger part 3968810 is instrumental in maintaining optimal operating temperatures. This component facilitates the transfer of thermal energy between two or more fluids without them coming into direct contact.

Integration with Engine Components

-

Cooling System: The heat exchanger works in tandem with the radiator and coolant pump to dissipate excess heat generated by the engine. As hot coolant from the engine passes through the heat exchanger, it transfers heat to the ambient air, which is then expelled, allowing the coolant to return to the engine at a lower temperature.

-

Turbocharger: In turbocharged engines, the heat exchanger is often employed to cool the compressed air before it enters the combustion chamber. This process increases air density, leading to more efficient combustion and enhanced engine performance.

-

Aftercooler: When integrated with an aftercooler, the heat exchanger reduces the temperature of the air that has been compressed by the turbocharger. This reduction in temperature increases the air’s density, which in turn allows for more fuel to be burned, resulting in increased power output and improved engine efficiency.

-

Intercooler: In engines with multiple stages of compression, the heat exchanger acts as an intercooler between stages to remove heat from the air, ensuring that each subsequent compression stage operates more efficiently.

-

Exhaust Gas Recirculation (EGR) System: The heat exchanger is also utilized in EGR systems to cool exhaust gases before they are recirculated back into the intake tract. This cooling process reduces the temperature of the recirculated gases, which helps lower combustion temperatures and reduce nitrogen oxide (NOx) emissions.

-

Charge Air Cooler: In diesel engines, the heat exchanger serves as a charge air cooler, cooling the air that has been compressed by the turbocharger before it enters the combustion chamber. This cooling enhances the efficiency of the combustion process and helps in achieving better fuel economy.

-

Transmission Cooling: Some engine systems incorporate the heat exchanger in the transmission cooling circuit. Here, it helps in dissipating heat from the transmission fluid, ensuring that the transmission operates within its optimal temperature range, thereby prolonging its lifespan and maintaining performance.

By effectively managing thermal energy, the heat exchanger part 3968810 plays a significant role in enhancing the efficiency, performance, and longevity of various engine components.

Conclusion

The Cummins 3968810 Heat Exchanger is a critical component in the thermal management of commercial truck engines. Its design and features ensure efficient heat transfer, contributing to engine efficiency, reliability, and longevity. Proper installation, maintenance, and integration with engine systems are essential for maximizing its benefits. The heat exchanger’s role in various engine components underscores its importance in enhancing overall engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.