This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

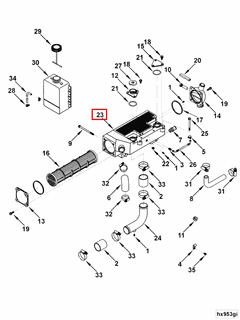

The Cummins Heat Exchanger Housing, part number 4003575, is a critical component in the cooling systems of commercial trucks. Cummins, a renowned manufacturer in the automotive industry, is known for producing high-quality components that enhance vehicle performance and reliability. This part is designed to contribute to the efficient operation of a truck’s cooling system, ensuring that the engine maintains optimal temperature under various operating conditions.

Basic Concepts of Heat Exchanger Housing

A Heat Exchanger Housing encases the heat exchanger, which is responsible for transferring heat between two or more fluids without them coming into direct contact. In the context of a truck’s cooling system, the Heat Exchanger Housing facilitates the transfer of heat from the engine coolant to the ambient air, helping to regulate engine temperature. This process is vital for maintaining engine efficiency and preventing overheating, which can lead to engine damage 1.

Purpose of the Heat Exchanger Housing

The Heat Exchanger Housing is designed to house and protect the heat exchanger within a truck’s cooling system. It plays a role in the cooling process by providing a secure enclosure for the heat exchanger, ensuring that it operates efficiently. The housing also contributes to overall engine efficiency by helping to maintain optimal engine temperature, which is essential for the engine’s performance and longevity.

Key Features

The Heat Exchanger Housing is characterized by several key features that enhance its performance and durability. These include a robust material composition that provides resistance to corrosion and wear, a design that ensures efficient heat transfer, and unique attributes such as precise engineering to fit snugly within the truck’s cooling system. These features contribute to the housing’s ability to withstand the demanding conditions of commercial truck operations.

Benefits

The advantages provided by the Heat Exchanger Housing include improved engine performance through efficient cooling, enhanced durability due to its robust construction, and potential cost savings through efficient operation. By maintaining optimal engine temperature, the housing contributes to the overall efficiency of the truck, which can lead to reduced fuel consumption and lower operating costs 2.

Installation and Integration

Installing the Heat Exchanger Housing involves several steps and considerations to ensure compatibility with various truck models and integration with existing cooling system components. Proper installation is essential for the housing to function effectively and contribute to the efficient operation of the truck’s cooling system.

Troubleshooting and Maintenance

Common issues that may arise with the Heat Exchanger Housing include leaks, corrosion, and reduced efficiency due to clogging or damage. Diagnostic methods for identifying problems may involve visual inspection, pressure testing, and performance monitoring. Maintenance practices to ensure longevity and optimal performance include regular inspection, cleaning, and replacement of worn or damaged components.

Performance Enhancements

The Heat Exchanger Housing contributes to overall truck performance by enhancing fuel efficiency, extending engine longevity, and reducing emissions. By ensuring efficient cooling, the housing helps to maintain optimal engine temperature, which is crucial for the engine’s performance and efficiency. This, in turn, can lead to reduced fuel consumption and lower emissions, contributing to a lower carbon footprint.

Safety Considerations

When handling and maintaining the Heat Exchanger Housing, it is important to follow safety protocols and considerations. This includes using proper handling techniques to avoid injury and ensuring that safety equipment, such as gloves and eye protection, is used when necessary. Adhering to these safety practices helps to ensure the well-being of individuals involved in the maintenance and operation of the truck.

Environmental Impact

The use of the Heat Exchanger Housing can have positive environmental benefits. By contributing to efficient engine operation and reduced fuel consumption, the housing helps to lower emissions and improve fuel efficiency. This leads to a reduced carbon footprint, making it a component that not only enhances truck performance but also contributes to environmental sustainability.

Cummins Overview

Cummins is a manufacturer with a rich history and a strong reputation in the industry for producing high-quality automotive components. Their commitment to excellence is evident in the design and performance of components like the Heat Exchanger Housing. Cummins’ dedication to innovation and quality has established them as a trusted name in the automotive and heavy-duty truck parts sector.

Engine Compatibility

Cummins 4B3.9

The Heat Exchanger Housing, part number 4003575, is specifically engineered to integrate with the Cummins 4B3.9 engine. This engine is known for its robust performance and reliability, often utilized in heavy-duty applications. The housing’s design ensures that it fits precisely within the engine’s architecture, facilitating effective heat exchange processes.

Installation and Functionality

The installation of the Heat Exchanger Housing in Cummins engines involves careful alignment and secure fitting. This housing is critical in directing coolant flow, which helps in dissipating heat generated by the engine. Its placement is crucial for maintaining the engine’s efficiency and longevity.

Engineering Precision

Cummins’ engineering precision ensures that the Heat Exchanger Housing is compatible with the specific thermal and mechanical requirements of the engines it is designed for. This compatibility is achieved through rigorous testing and adherence to stringent quality standards, ensuring that the housing performs optimally under various operating conditions.

Integration with Engine Systems

The integration of the Heat Exchanger Housing with Cummins engines is a testament to the brand’s commitment to providing reliable and efficient components. This housing works in tandem with other engine parts to create a balanced and efficient thermal management system, enhancing the overall performance of the engine.

Role of Part 4003575 Heat Exchanger Housing in Engine Systems

In engine systems, the Heat Exchanger Housing serves as a pivotal component in the thermal management system. This housing encases the heat exchanger, which is responsible for transferring thermal energy between two or more fluids without them coming into direct contact.

The Heat Exchanger Housing is integrated into the cooling system, where it works in conjunction with the radiator, thermostat, and coolant passages. Its primary function is to maintain optimal operating temperatures by facilitating the exchange of heat between the engine coolant and the ambient air.

In diesel engine systems, the Heat Exchanger Housing is often part of the Exhaust Gas Recirculation (EGR) cooler. Here, it helps in reducing nitrogen oxides (NOx) emissions by cooling the exhaust gases before they are reintroduced into the intake tract. This process lowers the combustion temperature, which in turn reduces the formation of NOx.

In gasoline engine systems, the Heat Exchanger Housing may be utilized in the charge air cooler (intercooler) system. In this application, it cools the compressed air from the turbocharger before it enters the combustion chamber, enhancing engine efficiency and power output.

Additionally, in hybrid and electric vehicle systems, the Heat Exchanger Housing plays a role in managing the thermal conditions of the battery pack. By regulating the temperature of the battery coolant, it ensures that the battery operates within its optimal temperature range, thereby prolonging its lifespan and maintaining performance.

Overall, the Heat Exchanger Housing is a fundamental component that contributes to the efficient and reliable operation of various engine systems by ensuring effective thermal management.

Conclusion

The Cummins Heat Exchanger Housing, part number 4003575, is a vital component in the thermal management systems of commercial trucks and various engine types. Its role in maintaining optimal engine temperatures contributes to enhanced performance, fuel efficiency, and reduced emissions. Proper installation, maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation ensures that the Heat Exchanger Housing meets the demanding requirements of modern engine systems, providing reliable and efficient thermal management solutions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.