This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

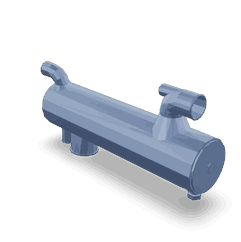

The Cummins 4020101 Heat Exchanger is a component designed for use in commercial trucks. Manufactured by Cummins Inc., a leader in the automotive industry, this heat exchanger is engineered to enhance the efficiency and reliability of truck engine systems. Its role is pivotal in maintaining optimal operating temperatures, thereby contributing to the overall performance and longevity of the vehicle.

Basic Concepts of Heat Exchangers

A heat exchanger is a system used to transfer heat between two or more fluids. These fluids can be liquids, gases, or a combination of both. The principle behind its operation involves the exchange of thermal energy without mixing the fluids. This is achieved through conductive surfaces that separate the fluids while allowing heat to pass through. Heat exchangers are integral in various applications, including engine cooling systems, where they help regulate temperatures to prevent overheating and ensure efficient operation 1.

Purpose of the Cummins 4020101 Heat Exchanger

The Cummins 4020101 Heat Exchanger plays a role in the engine cooling system by facilitating the transfer of heat from the engine coolant to the ambient air. This process helps maintain the engine within its optimal operating temperature range. Additionally, it may be utilized in other systems where heat management is crucial, such as in the cooling of transmission fluids or in auxiliary systems that require temperature regulation.

Key Features

The Cummins 4020101 Heat Exchanger is characterized by its robust design and the use of high-quality materials. It features a compact yet efficient structure that maximizes heat transfer while minimizing space requirements. The materials used are selected for their durability and resistance to corrosion, ensuring long-term performance even in demanding environments. Unique attributes of this heat exchanger include its high efficiency in heat transfer and its design that reduces the risk of clogging, enhancing its reliability.

Benefits

The advantages of the Cummins 4020101 Heat Exchanger include improved engine efficiency through effective temperature management, enhanced durability due to its construction materials, and potential cost savings for fleet operators through reduced maintenance needs and extended component lifespan. Its efficient design also contributes to lower fuel consumption, offering economic benefits over time.

Installation and Integration

Installing the Cummins 4020101 Heat Exchanger involves integrating it into the truck’s cooling system, following manufacturer guidelines to ensure proper fit and function. Considerations include ensuring compatibility with the existing system and adhering to any prerequisites for installation, such as system flushing or the use of specific coolants.

Performance and Efficiency

The Cummins 4020101 Heat Exchanger contributes to the overall performance and efficiency of a truck by maintaining engine temperatures within optimal ranges. This ensures that the engine operates efficiently, reducing the risk of overheating and associated damage. Data and examples may illustrate its impact on fuel efficiency and engine longevity, demonstrating its value in fleet operations 2.

Troubleshooting and Maintenance

Common issues with the Cummins 4020101 Heat Exchanger may include reduced efficiency due to clogging or corrosion. Regular maintenance practices, such as cleaning and inspection, can help ensure its longevity and optimal performance. Troubleshooting may involve checking for leaks, assessing the efficiency of heat transfer, and addressing any signs of wear or damage.

Comparative Analysis

When compared to other heat exchangers in the market, the Cummins 4020101 stands out for its design efficiency, durability, and performance. Differences may be observed in the materials used, the complexity of the design, and the overall effectiveness in heat transfer. These factors contribute to its competitive edge in the market.

Environmental Impact

The use of the Cummins 4020101 Heat Exchanger can positively affect environmental considerations by contributing to improved fuel efficiency and reduced emissions. Effective temperature management leads to more efficient engine operation, which in turn can lower fuel consumption and emissions, aligning with environmental goals.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to innovation and quality, Cummins has established itself as a trusted name in the automotive industry, providing solutions that enhance the performance, efficiency, and reliability of vehicles and equipment.

Compatibility

The Cummins Heat Exchanger part number 4020101 is designed to fit seamlessly with a range of Cummins engines, ensuring optimal performance and efficiency. This heat exchanger is engineered to work with the following engines:

- 6B5.9

- QSB5.9 CM850

- QSB6.7 M CM2250

For the 6B5.9 engine, the heat exchanger 4020101 plays a role in maintaining the engine’s thermal balance, ensuring that the engine operates within its optimal temperature range. This is vital for the longevity and reliability of the engine.

When it comes to the QSB5.9 CM850 and QSB6.7 M CM2250 engines, the heat exchanger 4020101 is equally important. These engines benefit from the precise temperature regulation provided by the heat exchanger, which helps in managing the engine’s cooling system effectively. This ensures that both engines perform at their best, with reduced risk of overheating or thermal stress.

The compatibility of the heat exchanger 4020101 with these engines is a testament to Cummins’ commitment to providing high-quality, reliable parts that enhance engine performance and durability.

Role in Engine Systems

The part 4020101 heat exchanger is an integral component in various engine systems, facilitating efficient thermal management. In internal combustion engines, it works in conjunction with the cooling system to regulate the temperature of the engine coolant. The heat exchanger transfers excess heat from the coolant to the surrounding air, ensuring that the engine operates within optimal temperature ranges.

In turbocharged engines, the heat exchanger plays a significant role in the intercooler system. Positioned between the turbocharger and the intake manifold, it cools the compressed air from the turbocharger before it enters the combustion chamber. This cooling process increases the air density, allowing for more efficient combustion and improved engine performance.

In diesel engines equipped with exhaust gas recirculation (EGR) systems, the heat exchanger is used to cool the recirculated exhaust gases. By reducing the temperature of the EGR gases, the heat exchanger helps to lower NOx emissions and improve overall engine efficiency.

Additionally, in hybrid and electric vehicles, the heat exchanger is utilized in the thermal management systems for the battery packs. It helps maintain the battery temperature within a specified range, ensuring optimal performance and longevity of the battery cells.

Overall, the part 4020101 heat exchanger is a versatile component that enhances the efficiency and reliability of various engine systems by effectively managing thermal energy.

Conclusion

The Cummins 4020101 Heat Exchanger is a critical component for maintaining optimal engine performance and efficiency in commercial trucks. Its robust design, high-quality materials, and efficient heat transfer capabilities make it a valuable asset for fleet operators. By ensuring proper temperature management, this Cummins part contributes to lower fuel consumption, reduced emissions, and extended engine lifespan, aligning with both economic and environmental goals.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.