This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

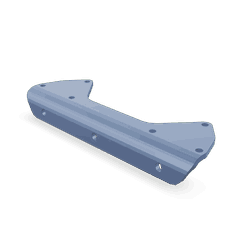

The Cummins 5277911 Heat Exchanger Bracket is a component designed to support the heat exchanger in commercial trucks. Its purpose is to provide a secure mounting point for the heat exchanger, ensuring it remains in place and functions effectively within the truck’s cooling system.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting structure for the heat exchanger, which is a part of the truck’s cooling system. The bracket’s function is to hold the heat exchanger securely in place, allowing it to operate efficiently. Proper mounting and support are vital for the heat exchanger to function correctly, as any movement or instability can affect its performance and the overall cooling efficiency of the engine 1.

Purpose of the Cummins 5277911 Heat Exchanger Bracket

This Cummins part plays a specific role in the truck’s cooling system by providing a stable platform for the heat exchanger. This support is crucial for maintaining the heat exchanger’s position and ensuring it can effectively transfer heat away from the engine. By supporting the heat exchanger, the bracket contributes to the efficient operation of the engine by helping to maintain optimal temperatures 2.

Key Features

The 5277911 is constructed from durable materials, designed to withstand the rigors of commercial truck operation. Its design includes features that enhance its performance and longevity, such as corrosion-resistant coatings and a robust attachment mechanism. These attributes ensure the bracket can support the heat exchanger under various operating conditions, contributing to the overall reliability of the truck’s cooling system 3.

Benefits

Using this part offers several benefits, including improved stability for the heat exchanger, which can lead to enhanced cooling efficiency. This, in turn, may contribute to engine longevity and performance by ensuring the engine operates within its optimal temperature range. The bracket’s design also aids in reducing vibrations that could otherwise affect the heat exchanger’s efficiency 4.

Installation Considerations

When installing the Heat Exchanger Bracket, it is important to follow guidelines and best practices to ensure proper mounting. This includes using the necessary tools, adhering to the correct steps for attachment, and ensuring the bracket is securely fastened to the truck’s frame. Proper installation is key to the bracket’s effectiveness in supporting the heat exchanger.

Troubleshooting and Maintenance

Common issues with heat exchanger brackets may include wear, corrosion, or damage. Regular inspection of the bracket can help identify these problems early. Maintenance or repair steps may involve cleaning the bracket, applying protective coatings, or replacing damaged components. Ensuring the bracket remains in good condition is important for the continued efficient operation of the heat exchanger and the truck’s cooling system.

Compatibility and Usage

The 5277911 is designed for specific types of trucks and engines. It is important to verify compatibility with the truck model and engine series to ensure proper fit and function. The bracket is suited for various usage scenarios and environmental conditions, making it a versatile component for commercial truck cooling systems.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation in engine and component manufacturing. With a history of producing reliable and high-performance parts, Cummins has built a reputation for excellence in the field. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Role of 5277911 Heat Exchanger Bracket in Engine Systems

The 5277911 is an essential component in the assembly and functionality of heat exchangers within various engine systems. This bracket securely mounts the heat exchanger to the engine, ensuring stability and proper alignment.

In the context of an engine system, the heat exchanger is responsible for transferring thermal energy between two or more fluids. The Heat Exchanger Bracket plays a significant role by providing a robust attachment point that withstands the vibrations and stresses inherent in engine operation.

When integrated with the engine, the bracket allows for efficient heat transfer processes. It ensures that the heat exchanger remains in optimal position, facilitating the exchange of heat between the engine coolant and the surrounding air or other fluids. This process is vital for maintaining engine temperature within safe operating limits, enhancing overall engine performance and reliability.

Additionally, the bracket’s design contributes to the structural integrity of the heat exchanger, preventing potential misalignments that could lead to reduced efficiency or damage. Its integration with the engine system also simplifies maintenance procedures, allowing for easier access to the heat exchanger for inspection or replacement.

Conclusion

In summary, the 5277911 Heat Exchanger Bracket is a fundamental component that ensures the heat exchanger operates effectively within the engine system, contributing to the engine’s thermal management and longevity.

-

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice, Jones Bartlett Learning, 2018.

↩ -

Zhiyu Han, Simulation and Optimization of Internal Combustion Engines, SAE International, 2022.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.