5289014

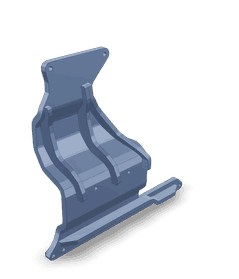

Heat Exchanger Bracket

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Heat Exchanger Bracket 5289014, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty vehicles. This Cummins part is part of this extensive lineup, playing a significant role in the cooling systems of commercial trucks 3.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting component for heat exchangers within a truck’s cooling system. Its primary function is to secure the heat exchanger in place, ensuring it operates efficiently by facilitating the transfer of heat between fluids at different temperatures. This process is vital for maintaining optimal engine temperature, which in turn affects the overall performance and longevity of the truck’s engine 4.

Purpose of the 5289014 Heat Exchanger Bracket

The 5289014 Heat Exchanger Bracket is integral to the operation of a truck’s cooling system. It provides a stable platform for the heat exchanger, allowing for efficient heat transfer. This bracket is designed to work in conjunction with other cooling system components, such as the radiator and engine coolant system, to maintain engine temperature within specified limits 1.

Key Features

The 5289014 Heat Exchanger Bracket is constructed from high-quality materials, ensuring durability and resistance to the harsh conditions encountered in commercial truck operations. Its design includes features that enhance its functionality, such as precise mounting points for secure attachment and a structure that allows for efficient airflow around the heat exchanger 2.

Benefits

The use of the 5289014 Heat Exchanger Bracket offers several advantages. It contributes to improved cooling system efficiency, which can lead to better engine performance. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. Additionally, the bracket’s design enhances the overall stability of the heat exchanger, contributing to the consistent operation of the cooling system 3.

Installation Process

Installing the 5289014 Heat Exchanger Bracket requires careful attention to detail to ensure proper functionality. The process involves securing the bracket to the truck’s frame, followed by mounting the heat exchanger onto the bracket. It is important to follow manufacturer guidelines to avoid potential issues such as misalignment or insecure attachment, which could affect the cooling system’s performance 4.

Common Issues and Troubleshooting

Frequent problems with the 5289014 Heat Exchanger Bracket may include misalignment, corrosion, or damage from physical impact. Troubleshooting these issues involves inspecting the bracket for signs of wear or damage, ensuring it is securely attached, and addressing any corrosion with appropriate treatments. Regular checks can help identify and resolve these issues before they lead to more significant problems 1.

Maintenance Tips

To ensure the longevity and optimal performance of the 5289014 Heat Exchanger Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, ensuring all mounting points are secure, and cleaning the area around the heat exchanger to maintain efficient airflow. Adhering to these maintenance practices can help prevent issues and ensure the cooling system operates effectively 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of heavy-duty vehicles 3.

Compatibility with Cummins Engines

The Cummins Heat Exchanger Bracket part number 5289014 is designed to fit seamlessly with several Cummins engine models, ensuring optimal performance and reliability. This bracket is integral to the engine’s cooling system, providing a secure mounting point for the heat exchanger.

One of the engines that this bracket is compatible with is the ISL G CM2180. This engine is known for its robust design and high performance, making it a popular choice in various applications. The Heat Exchanger Bracket 5289014 ensures that the heat exchanger is properly aligned and secured, which is crucial for maintaining the engine’s efficiency and longevity.

Additionally, this bracket is also suitable for other Cummins engines within the same family, ensuring a standardized fit across multiple models. This compatibility allows for easier maintenance and repair, as the same part can be used across different engine types, reducing the need for specialized components.

The design of the Heat Exchanger Bracket 5289014 takes into account the specific requirements of Cummins engines, ensuring that it can withstand the rigors of heavy-duty operation. Its robust construction and precise engineering make it a reliable choice for maintaining the integrity of the engine’s cooling system 3.

Role of Part 5289014 Heat Exchanger Bracket in Engine Systems

The part 5289014 Heat Exchanger Bracket is an essential component in the assembly and functionality of heat exchangers within various engine systems. This bracket securely mounts the heat exchanger to the engine structure, ensuring stability and proper alignment.

In liquid-cooled engines, the heat exchanger bracket facilitates the attachment of the heat exchanger to the engine block or cylinder head. This allows for efficient heat transfer from the engine coolant to the surrounding air, maintaining optimal operating temperatures.

For air-cooled engines, the bracket plays a similar role by positioning the heat exchanger in a manner that maximizes airflow over the fins, enhancing the dissipation of heat generated by the engine.

Additionally, in hybrid engine systems that utilize both liquid and air cooling methods, the heat exchanger bracket ensures that the components are correctly aligned to work in tandem, providing a balanced cooling solution.

The secure mounting provided by the bracket also prevents vibrations and movement that could lead to inefficiencies or damage to the heat exchanger and associated components. This contributes to the overall reliability and performance of the engine system 4.

Conclusion

The 5289014 Heat Exchanger Bracket by Cummins is a critical component in the cooling systems of commercial trucks, ensuring efficient heat transfer and maintaining optimal engine temperatures. Its durable construction, precise design, and compatibility with various Cummins engines make it a reliable choice for heavy-duty operations. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Gifford, C. (2014). Cars Encyclopedia. DK Publishing.

↩ ↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.