5289017

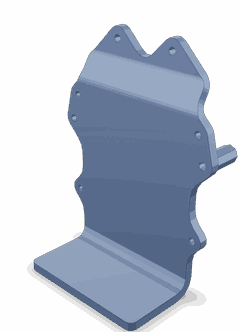

Heat Exchanger Bracket

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Heat Exchanger Bracket, part number 5289017, is a component designed to support the efficient operation of heavy-duty trucks. This bracket plays a role in the truck’s cooling system by ensuring that the engine operates within optimal temperature ranges. Its design and functionality contribute to the overall reliability and performance of the vehicle.

Basic Concepts of Heat Exchanger Brackets

A heat exchanger bracket serves as a mounting structure for the heat exchanger within a truck’s cooling system. It facilitates the secure attachment of the heat exchanger to the truck’s frame, allowing for efficient heat transfer between the engine coolant and the ambient air. This bracket interfaces with various components, including the heat exchanger itself, the truck’s frame, and potentially other cooling system elements, to maintain a stable operating temperature for the engine.

Purpose of the Heat Exchanger Bracket

The Heat Exchanger Bracket is integral to the operation of a truck’s cooling system. It supports the heat exchanger, ensuring it remains in the correct position and orientation for optimal heat dissipation. By securely mounting the heat exchanger, this bracket contributes to the efficiency and reliability of the cooling system, helping to prevent engine overheating and potential damage.

Key Features

The Heat Exchanger Bracket boasts several key features that enhance its performance. Constructed from durable materials, it is designed to withstand the rigors of heavy-duty truck operation. Its design includes precise mounting points and alignment features to ensure the heat exchanger is correctly positioned. Additionally, the bracket may incorporate unique attributes such as corrosion-resistant coatings or vibration-dampening elements to further improve its durability and effectiveness.

Benefits

The implementation of the Heat Exchanger Bracket offers several benefits. It facilitates improved heat dissipation by ensuring the heat exchanger operates in an optimal configuration. The durable construction of the bracket enhances the longevity of the cooling system components, potentially leading to cost savings for fleet operators through reduced maintenance and replacement needs.

Installation Process

Installing the Heat Exchanger Bracket requires careful attention to detail. The process begins with ensuring the truck’s frame is clean and free of debris. The bracket should be aligned with the designated mounting points on the frame, and secured using the appropriate fasteners. It is important to verify that the heat exchanger is correctly positioned within the bracket and that all connections are secure to ensure optimal performance.

Maintenance and Troubleshooting

Regular maintenance of the Heat Exchanger Bracket is crucial for ensuring its longevity and optimal performance. This includes inspecting the bracket and its fasteners for signs of wear or corrosion, and ensuring that the heat exchanger remains securely mounted. Common issues may include loose fasteners or corrosion, which can be addressed by tightening or replacing affected components as necessary.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial and industrial applications.

Compatibility with Engine Models

The Heat Exchanger Bracket, part number 5289017, is designed to fit seamlessly with several engine models, including the ISL G, M, Q, L, and K series. This compatibility ensures that the heat exchanger is securely positioned, allowing for optimal heat dissipation and system performance across different engine types.

Role of the Heat Exchanger Bracket in Engine Systems

The Heat Exchanger Bracket, identified by part number 5289017, is an integral component in the assembly and operation of heat exchangers within various engine systems. This bracket serves as a foundational support structure, ensuring the heat exchanger is securely positioned and aligned within the engine’s architecture.

In the context of an engine system, the heat exchanger is responsible for transferring thermal energy between two or more fluids, which may include coolant, oil, or air. The efficient operation of the heat exchanger is paramount for maintaining optimal engine temperature, enhancing performance, and ensuring longevity of engine components.

The Heat Exchanger Bracket facilitates this by providing a stable mounting point for the heat exchanger. It allows for precise alignment with other engine components, such as the radiator, coolant passages, and air intake systems. This alignment is essential for the effective flow of fluids through the heat exchanger, ensuring that heat transfer occurs efficiently.

Moreover, the bracket contributes to the structural integrity of the engine system. It absorbs and distributes mechanical stresses that may arise from engine vibrations, thermal expansion, and other operational dynamics. This helps in preventing potential damage to the heat exchanger and connected components, thereby maintaining the overall reliability of the engine system.

Conclusion

The Heat Exchanger Bracket, part number 5289017, plays a significant role in the functional and structural aspects of engine systems by supporting the heat exchanger and ensuring its proper integration within the engine’s complex network of components. Its durable construction, precise design, and compatibility with various engine models make it a critical component for maintaining optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.