This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3349405 Heat Shield is a component designed to manage and mitigate heat in heavy-duty truck operations. Its purpose is to protect surrounding components and structures from excessive heat generated by the engine and exhaust system. This part plays a role in maintaining the integrity and efficiency of the truck’s systems by providing a barrier against heat transfer 3.

Basic Concepts of Heat Shields

Heat shields are components used in vehicles to redirect and dissipate heat away from sensitive parts and structures. They function by reflecting and absorbing heat, thereby reducing the temperature in critical areas. The importance of heat shields in vehicle systems lies in their ability to protect components from thermal damage, enhance engine efficiency, and ensure the safety of the vehicle’s operation 1.

Purpose of the Cummins 3349405 Heat Shield

The Cummins 3349405 Heat Shield is specifically designed to protect certain areas of a truck from the high temperatures produced by the engine and exhaust system. It is positioned in areas where heat could potentially damage other components or structures. By doing so, it helps maintain the operational integrity of the truck and contributes to the overall efficiency and safety of the vehicle 3.

Key Features

The Cummins 3349405 Heat Shield is constructed from materials that offer high thermal resistance and durability. Its design includes elements that enhance its ability to reflect and dissipate heat effectively. Unique characteristics such as its shape and surface treatment contribute to its performance, ensuring it can withstand the demanding conditions of heavy-duty truck operations 2.

Benefits of Using the Cummins 3349405 Heat Shield

Utilizing the Cummins 3349405 Heat Shield provides several advantages. It offers thermal protection to surrounding components, potentially improving their longevity and performance. The shield’s durability ensures it can withstand the rigors of heavy-duty use, and its effective heat management may contribute to enhanced engine efficiency. Additionally, by reducing the risk of heat-related damage, it plays a role in improving overall vehicle safety 3.

Installation Considerations

When installing the Cummins 3349405 Heat Shield, it is important to follow guidelines and best practices to ensure proper fit and function. Preparatory steps may include cleaning the installation area and inspecting the shield for any damage. Tools required for installation might include fasteners and possibly a heat gun for shaping the shield if necessary. Alignment considerations are crucial to ensure the shield effectively covers the intended area and performs its function without interfering with other components 3.

Maintenance and Troubleshooting

Maintaining the Cummins 3349405 Heat Shield involves regular inspections for signs of wear, damage, or displacement. Common issues may include corrosion, physical damage from road debris, or loosening of fasteners. Troubleshooting tips include ensuring the shield is securely fastened, replacing any damaged sections, and cleaning the shield to remove any buildup that could affect its performance 3.

Compatibility and Application

The Cummins 3349405 Heat Shield is designed for specific types of trucks and engine models. It is important to consult the manufacturer’s guidelines for compatibility and application notes to ensure the shield is suitable for the intended vehicle 3.

Safety Considerations

When handling and installing the Cummins 3349405 Heat Shield, it is important to follow safety guidelines. This includes wearing protective equipment such as gloves and safety glasses. Operational safety measures should also be observed to prevent accidents during installation and ensure the shield functions correctly within the vehicle’s system 3.

Environmental Impact

The production, use, and disposal of the Cummins 3349405 Heat Shield have environmental considerations. Efforts should be made to minimize waste during production, use materials that are recyclable where possible, and ensure proper disposal methods are followed to reduce environmental impact 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and approximately 7,400 dealer locations 3.

Application with Cummins Engines

K50 Engine Series

The K50 engine series by Cummins benefits significantly from the installation of the Heat Shield part 3349405. This part is specifically designed to fit around the exhaust manifold and other high-temperature areas of the engine. By doing so, it reduces the amount of heat transferred to the engine block, thereby protecting sensitive components and improving the engine’s longevity 3.

Grouping of Engines

The Heat Shield part 3349405 is versatile and can be applied across multiple engine models within the K50 series. Its design accommodates the unique thermal profiles of these engines, ensuring that each model benefits from the heat reduction properties of the shield. This makes it an essential part for maintaining engine efficiency and performance across the board 3.

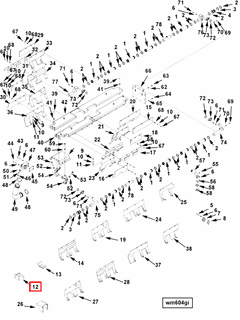

Installation Considerations

When installing the Heat Shield part 3349405, it is crucial to follow the manufacturer’s guidelines to ensure a proper fit. This involves precise alignment with the engine’s exhaust manifold and other high-heat components. Proper installation not only enhances the engine’s thermal management but also contributes to the overall reliability and performance of the engine 3.

Role of Part 3349405 Heat Shield in Engine Systems

The 3349405 Heat Shield is a component in managing thermal dynamics within engine systems. It is strategically positioned to interact with several key components, ensuring optimal performance and protection 3.

Interaction with Heat Shield Bracket and Left Mounting

The heat shield works in conjunction with the heat shield bracket and the left mounting to create a robust thermal barrier. This setup is designed to protect adjacent components from excessive heat, maintaining structural integrity and operational efficiency 3.

Manifold Protection

When installed near the manifold, the heat shield mitigates the high temperatures generated during combustion. This protection helps in preserving the manifold’s material properties and ensures consistent engine performance over time 3.

Water System Components

In systems involving water tubes and water transfer components, the heat shield plays a significant role. It prevents heat from affecting the water tubes, which are vital for cooling and maintaining engine temperature. Additionally, it safeguards the water transfer tube, ensuring efficient heat dissipation and preventing potential leaks or failures 3.

Overall Thermal Management

By effectively managing heat around these components, the 3349405 Heat Shield contributes to the overall thermal management of the engine. This not only enhances the durability of the engine components but also ensures that the engine operates within its designed temperature range, leading to improved performance and reliability 3.

Conclusion

The Cummins 3349405 Heat Shield is a vital component in the thermal management of heavy-duty trucks and Cummins engines. Its design and features contribute to the protection of sensitive components, enhancement of engine efficiency, and overall vehicle safety. Proper installation, maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this part.

-

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩ -

Parikyan, Tigran Ed. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ -

Hilgers, Michael. Vocational Vehicles and Applications. Springer Nature, 2023.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.