This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

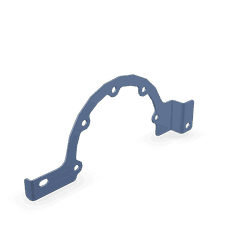

The Cummins 3643666 Heat Shield is a component designed to protect various parts of a heavy-duty truck from excessive heat. Its role is vital in maintaining the integrity and efficiency of the vehicle’s engine and surrounding components. By mitigating heat exposure, the heat shield contributes to the overall performance and safety of the truck.

Purpose of the Heat Shield

The Cummins 3643666 Heat Shield serves to protect critical components of a heavy-duty truck from the intense heat generated by the engine and exhaust system. This protection helps prevent heat-related damage to nearby parts, ensuring they operate within their designed temperature ranges. By maintaining optimal temperatures, the heat shield plays a role in enhancing the efficiency and safety of the vehicle. It also helps in reducing thermal stress on engine components, which can lead to improved longevity and performance 1.

Key Features

The Cummins 3643666 Heat Shield is engineered with specific design and material characteristics to effectively manage heat. It is constructed from materials that offer high heat resistance and durability, ensuring it can withstand the demanding conditions of heavy-duty truck operations. The heat shield is designed to fit precisely within the truck’s engine compartment, providing comprehensive coverage for targeted components 2.

Benefits

Installing the Cummins 3643666 Heat Shield offers several advantages. It enhances the longevity of protected components by shielding them from excessive heat, which can cause premature wear and failure. Improved safety for nearby parts is another benefit, as the heat shield prevents heat-induced damage that could lead to malfunctions or accidents. Additionally, by reducing thermal stress on engine components, the heat shield may contribute to potential fuel efficiency improvements 3.

Installation Process

Proper installation of the Cummins 3643666 Heat Shield is crucial for its effectiveness. The process involves positioning the heat shield correctly within the engine compartment and securing it in place using the provided fasteners. Careful attention to detail during installation ensures that the heat shield functions optimally, providing the intended protection and performance benefits 4.

Maintenance and Troubleshooting

Regular inspection and maintenance of the Cummins 3643666 Heat Shield are important to ensure its continued effectiveness. Checking for signs of wear, damage, or loose fasteners allows for timely repairs or replacements, maintaining vehicle performance and safety. Common issues may include heat shield warping or detachment, which can be addressed by re-securing or replacing the affected part 5.

Compatibility and Application

The Cummins 3643666 Heat Shield is designed for use in specific types of trucks and engine models. It is important to use manufacturer-recommended parts to ensure compatibility and optimal performance. This ensures that the heat shield fits correctly and functions as intended within the vehicle’s engine compartment.

Safety Considerations

When handling and installing the Cummins 3643666 Heat Shield, it is important to follow safety protocols to prevent accidents and ensure proper functionality. This includes adhering to manufacturer guidelines for installation and maintenance, as well as taking precautions to avoid burns or injuries from hot surfaces.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, particularly known for its production of heavy-duty truck components. With a rich history of innovation and quality, Cummins plays a significant role in providing reliable and efficient solutions for the transportation sector. The company’s commitment to excellence is evident in its wide range of products, including the 3643666 Heat Shield, which is designed to meet the rigorous demands of heavy-duty truck operations.

Role of Part 3643666 Heat Shield in Engine Systems

The Cummins 3643666 Heat Shield is an essential component in managing thermal dynamics within engine systems. It is strategically positioned to safeguard various engine components from excessive heat generated during operation.

Interaction with Key Components

-

Exhaust Manifold: The heat shield is placed adjacent to the exhaust manifold to mitigate heat transfer to nearby components. This helps in maintaining the structural integrity of the manifold and prevents heat-induced damage to the surrounding areas 6.

-

Turbocharger: In turbocharged engines, the heat shield plays a significant role in protecting the turbocharger from radiant heat. This ensures optimal performance and longevity of the turbocharger, which is sensitive to temperature fluctuations 7.

-

Wiring Harnesses: Electrical components and wiring harnesses are particularly vulnerable to heat. The heat shield acts as a barrier, preventing heat from affecting the insulation and conductivity of these wires, thereby ensuring reliable electrical performance 8.

-

Fuel Lines: The heat shield is also utilized to protect fuel lines from heat, which can cause fuel to degrade or even ignite under extreme conditions. This is vital for maintaining the integrity of the fuel system and ensuring safe operation 9.

-

Engine Bay Components: Various other components within the engine bay, such as sensors, connectors, and secondary air injection systems, benefit from the presence of the heat shield. It helps in creating a more stable thermal environment, which is essential for the consistent operation of these parts 10.

Conclusion

In summary, the Cummins 3643666 Heat Shield is integral to maintaining a balanced thermal environment within the engine system, protecting both mechanical and electrical components from the adverse effects of heat. Its proper installation and maintenance are crucial for ensuring the longevity and efficiency of the vehicle’s engine and surrounding components.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Cummins Inc. (n.d.). Service Manual (6314864).

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Osgood, L., Cameron, G., & Christensen, E. (2024). Engineering Mechanics: Statics. Creative Commons.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Cummins Inc. (n.d.). Service Manual (6314864).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.