This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

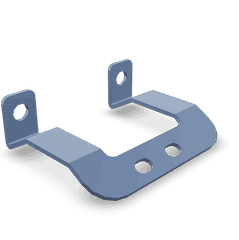

The Cummins 3644417 Heat Shield is a component designed for use in heavy-duty truck operations. Its primary function is to manage and mitigate the effects of high temperatures generated by the engine and exhaust system. By doing so, it helps protect nearby components and enhances the overall safety and efficiency of the vehicle.

Basic Concepts of Heat Shields

Heat shields are components used in vehicles to redirect, reflect, or absorb heat produced by the engine and exhaust system. They play a role in maintaining the integrity of surrounding parts by preventing heat damage. Heat shields are essential for ensuring that critical components operate within their designed temperature ranges, thereby contributing to the longevity and reliability of the vehicle 1.

Purpose of the Cummins 3644417 Heat Shield

The Cummins 3644417 Heat Shield is specifically engineered to address the thermal challenges faced by heavy-duty trucks. It is positioned to shield sensitive parts from direct exposure to high temperatures emanating from the engine and exhaust. This placement helps in maintaining optimal operating conditions for these components, reducing the risk of heat-related damage and improving the overall performance of the truck.

Key Features

The Cummins 3644417 Heat Shield is constructed from high-quality materials that offer excellent thermal resistance. Its design includes features such as precise cutouts and mounting points to ensure a secure fit and effective heat management. The shield’s material composition and design elements work together to provide robust protection against heat, enhancing its performance in demanding environments.

Benefits of Using the Cummins 3644417 Heat Shield

Utilizing the Cummins 3644417 Heat Shield offers several advantages. It provides thermal protection to nearby components, helping to maintain their structural integrity and functional efficiency. The shield’s durable construction ensures long-term performance, even under harsh operating conditions. Additionally, by managing heat more effectively, it can contribute to improved engine efficiency and overall vehicle safety.

Installation Considerations

Installing the Cummins 3644417 Heat Shield requires attention to detail to ensure proper fitment and function. Preparatory steps include cleaning the installation area and inspecting the shield for any damage. The necessary tools for installation may include wrenches, screws, and possibly a heat gun for shaping the shield if required. Alignment procedures should follow the manufacturer’s guidelines to ensure the shield is positioned correctly for maximum effectiveness.

Maintenance and Troubleshooting

Maintaining the Cummins 3644417 Heat Shield involves regular inspections for signs of wear, corrosion, or damage. Common issues may include gaps in coverage due to misalignment or physical damage from road debris. Troubleshooting steps include realigning the shield, repairing minor damage, or replacing the shield if it is significantly compromised. Consistent maintenance helps ensure the shield continues to provide effective thermal protection.

Performance in Various Conditions

The Cummins 3644417 Heat Shield is designed to perform under a range of operating conditions. It effectively manages heat in extreme temperatures, whether the truck is operating in hot or cold climates. Under heavy loads and varied terrains, the shield maintains its protective function, ensuring that sensitive components remain within their optimal temperature ranges.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly for heavy-duty truck components, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its standing as a trusted name in the industry.

Application in Cummins Engines

QSK38 and CM2150 Engines

The 3644417 heat shield is specifically designed to fit the QSK38 and CM2150 engines. These engines are known for their robust construction and high performance, often used in heavy-duty applications such as construction equipment and marine vessels. The heat shield’s placement around these engines is crucial for maintaining the integrity of surrounding components, such as fuel lines and electrical wiring, which can be adversely affected by high temperatures.

MCRS Engines

Similarly, the MCRS engines benefit from the 3644417 heat shield. These engines are typically used in a variety of industrial applications where reliability and efficiency are paramount. The heat shield’s role here is to prevent heat transfer to adjacent parts, ensuring that the engine operates within its optimal temperature range.

Installation and Functionality

The installation of the 3644417 heat shield is straightforward, designed to fit snugly and securely around the engine’s hot components. Its material is chosen for its ability to withstand high temperatures and provide a barrier against heat transfer. This ensures that the engine remains cool and efficient, reducing the risk of overheating and extending the lifespan of the engine.

Importance in Engine Maintenance

Regular inspection and replacement of the 3644417 heat shield are essential for maintaining engine health. Over time, the heat shield may degrade due to constant exposure to high temperatures. Ensuring that this part is in good condition is a key aspect of preventative maintenance, helping to avoid costly repairs and downtime.

Role of Part 3644417 Heat Shield in Engine Systems

The heat shield, specifically part 3644417, is an essential component in the thermal management of engine systems. It is strategically positioned to protect adjacent components from the intense heat generated by the engine and exhaust system.

In the context of the engine block, the heat shield mitigates the transfer of heat to nearby electrical components, ensuring their reliable operation and longevity. It also plays a significant role in safeguarding the vehicle’s undercarriage from heat damage, which can lead to degradation of materials and potential safety hazards.

When considering the exhaust manifold, the heat shield is vital in reducing the temperature around the manifold, preventing heat soak which can affect engine performance and fuel efficiency. It also protects the surrounding chassis components from the high temperatures emitted by the manifold during operation.

In relation to the turbocharger, the heat shield helps in maintaining optimal operating temperatures. By reducing the heat transferred to the turbocharger, it aids in preserving the lubricants’ viscosity and preventing premature wear of the turbocharger components.

Furthermore, the heat shield is instrumental in the protection of the catalytic converter. By minimizing heat loss, it ensures that the catalytic converter reaches and maintains its operating temperature more efficiently, thereby enhancing its effectiveness in reducing harmful emissions.

Overall, the integration of part 3644417 heat shield in engine systems is a testament to the importance of thermal management in ensuring the durability, performance, and safety of automotive components.

Conclusion

The Cummins 3644417 Heat Shield is a vital component in the thermal management of heavy-duty truck engines. Its design and material composition ensure effective heat management, contributing to the longevity and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring optimal engine performance and safety.

-

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.