This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

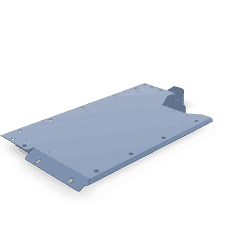

The Cummins 3644419 Heat Shield is engineered to manage and mitigate the effects of high temperatures in heavy-duty truck operations. It protects adjacent parts and the vehicle’s structure from excessive heat generated by the engine and exhaust system, maintaining the integrity and efficiency of the truck’s components under demanding conditions 3.

Basic Concepts of Heat Shields

Heat shields in vehicles are designed to redirect and dissipate heat away from sensitive parts and structures. They function by reflecting and absorbing thermal energy, reducing the temperature impact on nearby components. This enhances durability, improves safety, and maintains optimal performance of the engine and other critical systems 1.

Purpose of the Cummins 3644419 Heat Shield

This Cummins part is specifically designed to protect certain areas of a heavy-duty truck from the intense heat produced by the engine and exhaust. It is strategically placed to cover and shield components that are particularly vulnerable to heat damage, preserving their structural integrity and ensuring they operate within their designed temperature ranges 3.

Key Features

The Cummins 3644419 Heat Shield is constructed from high-quality materials that offer superior heat resistance and durability. Its design includes a reflective surface to deflect heat and a robust frame to withstand heavy-duty use. Precision engineering ensures exact fitment, and enhanced thermal performance features are incorporated 2.

Benefits of Using the Cummins 3644419 Heat Shield

Utilizing this heat shield provides effective thermal protection to nearby components, leading to increased durability and longevity of the truck’s parts. It also contributes to improved engine efficiency and overall vehicle safety by reducing the risk of heat-related failures 3.

Installation Considerations

When installing the Cummins 3644419 Heat Shield, it is important to follow guidelines and best practices to ensure proper fitment and function. Preparatory steps may include cleaning the installation area and inspecting the shield for any damage. Tools required for installation might include fasteners and possibly a heat gun for shaping the shield if necessary. Alignment procedures should be carefully followed to ensure the shield covers the intended areas effectively 1.

Troubleshooting Common Issues

Typical problems that may arise with heat shields include rust, detachment, or thermal degradation. Addressing these issues involves inspecting the shield regularly for signs of wear or damage, ensuring it remains securely attached, and replacing it if significant degradation is observed. Maintenance tips include keeping the shield clean and free from debris that could impede its function 2.

Maintenance Practices

To ensure the longevity and optimal performance of the Cummins 3644419 Heat Shield, recommended maintenance routines include regular inspections for damage or wear. Cleaning procedures should be performed to remove any buildup that could affect the shield’s efficiency. Inspection intervals should be aligned with the truck’s maintenance schedule to facilitate early detection of any issues 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive industry. Its product range includes a variety of engines and components designed for heavy-duty applications, reflecting a commitment to excellence and customer satisfaction 3.

Role of Part 3644419 Heat Shield in Engine Systems

In engine systems, the Cummins 3644419 heat shield is strategically positioned to safeguard various components from excessive heat generated during operation. Its primary function is to mitigate thermal stress and prevent heat-induced damage to adjacent parts.

Interaction with Key Components

- Exhaust Manifolds: The heat shield is often placed near exhaust manifolds to protect wiring harnesses, fuel lines, and other sensitive components from the intense heat produced by exhaust gases.

- Turbochargers: In turbocharged engines, the heat shield helps maintain optimal operating temperatures for the turbocharger, preventing heat soak and premature wear.

- Wiring Harnesses: Electrical components and wiring harnesses are particularly vulnerable to heat damage. The heat shield ensures these parts remain within safe temperature ranges, preserving their integrity and functionality.

- Fuel Lines: Fuel lines can be adversely affected by high temperatures, leading to potential leaks or reduced efficiency. The heat shield acts as a barrier, maintaining the structural and operational integrity of the fuel lines.

- Engine Bay Components: Various engine bay components, including sensors and control units, benefit from the presence of the heat shield. It helps create a more stable thermal environment, enhancing the reliability and performance of these parts.

- Underbody Components: In some applications, the heat shield is used to protect underbody components from heat radiated by the exhaust system. This includes shielding parts of the chassis and suspension system to prevent heat-related degradation.

The effective placement and design of the Cummins 3644419 heat shield are essential for maintaining the overall health and efficiency of the engine system. By reducing thermal stress on critical components, it contributes to the longevity and performance of the engine 3.

Conclusion

The Cummins 3644419 Heat Shield plays a vital role in protecting heavy-duty truck components from excessive heat, ensuring optimal performance and longevity. Its strategic placement and robust design contribute to the overall efficiency and safety of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this essential component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.