This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

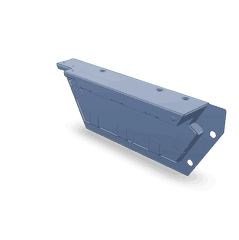

The Cummins 4310237 Heat Shield is a component designed to protect various parts of commercial trucks from excessive heat. It is integral to maintaining the operational integrity and safety of truck systems by shielding sensitive components from the high temperatures generated during engine operation 1.

Basic Concepts of Heat Shields

Heat shields are protective barriers that mitigate the transfer of heat from high-temperature sources to surrounding areas. They function by reflecting and absorbing heat, thereby preventing damage to adjacent components. In vehicle systems, heat shields play a significant role in ensuring the longevity and safety of various parts by maintaining optimal operating temperatures 2.

Purpose of the Cummins 4310237 Heat Shield

The Cummins 4310237 Heat Shield is specifically designed to protect critical components of a truck from the intense heat produced by the engine and exhaust system. By doing so, it helps maintain the structural integrity and functionality of these parts, ensuring they operate within safe temperature ranges 3.

Key Features

The Cummins 4310237 Heat Shield is constructed from high-quality materials that offer excellent heat resistance. Its design includes specific elements that enhance its effectiveness, such as precise shaping to fit snugly around targeted areas and durable coatings that improve heat reflection and absorption capabilities 4.

Benefits of Using the Cummins 4310237 Heat Shield

Installing the Cummins 4310237 Heat Shield offers several advantages. It contributes to the prolonged lifespan of protected components by reducing thermal stress. Additionally, it enhances overall safety by preventing heat-related damage that could lead to failures. Performance benefits may also be observed as components operate more efficiently within their designed temperature parameters 5.

Installation Considerations

Proper installation of the Cummins 4310237 Heat Shield is vital for its effectiveness. Guidelines recommend ensuring a secure fit to prevent heat leakage and verifying that all fasteners are correctly tightened. It is also important to check for any obstructions that could interfere with the shield’s function 6.

Maintenance and Troubleshooting

Regular maintenance checks for the Cummins 4310237 Heat Shield involve inspecting for signs of wear or damage, such as warping or corrosion. Common issues may include loose fittings or degradation of the shield material. Troubleshooting tips include re-securing any loose components and replacing the shield if significant damage is detected 7.

Compatibility and Application

The Cummins 4310237 Heat Shield is designed for use in specific truck models and engine configurations. Its application is tailored to fit within the thermal management systems of these vehicles, ensuring compatibility and effective heat protection 8.

Safety Precautions

When handling and installing heat shields, it is important to observe safety measures to prevent injuries and ensure proper functionality. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before installation, and following all manufacturer guidelines 9.

Role of Part 4310237 Heat Shield in Engine Systems

In the complex arrangement of an engine system, the Cummins 4310237 Heat Shield serves a significant function by providing thermal protection to various components. When integrated with the turbocharger, the heat shield helps in maintaining optimal operating temperatures. The turbocharger, which compresses the air entering the engine, can reach extremely high temperatures. The heat shield mitigates the transfer of this heat to surrounding components, ensuring that the turbocharger operates efficiently without overheating adjacent parts.

Additionally, the heat shield plays a role in protecting the engine’s electrical components and wiring harnesses. These elements are sensitive to high temperatures and can suffer from insulation breakdown or reduced performance if exposed to excessive heat. By shielding these components, the heat shield ensures their longevity and reliable operation.

In the context of the engine’s overall thermal management, the heat shield also contributes to the stability of the engine bay’s temperature. This is particularly important in high-performance engines where components operate under extreme conditions. The shield helps in reducing the overall heat load within the engine compartment, which can lead to improved engine performance and durability.

Furthermore, the heat shield aids in the protection of the engine’s structural components. Materials used in engine construction can degrade over time when exposed to consistent high temperatures. The shield acts as a barrier, reducing the thermal stress on these materials and contributing to the structural integrity of the engine over its lifespan 10.

Conclusion

The Cummins 4310237 Heat Shield is an integral component in the thermal management strategy of an engine system. Its role in protecting turbochargers, electrical components, and structural elements underscores its importance in maintaining the efficiency and reliability of the engine.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.