This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

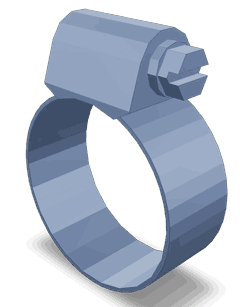

The Hose Clamp 3016190, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, is known for its robust and reliable parts. This part is significant in maintaining the integrity of fluid systems within trucks, ensuring efficient and safe operation.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight and leak-free connection. Their primary function is to maintain the integrity of fluid systems by preventing leaks and ensuring consistent fluid flow. Proper sealing is vital in these systems to avoid fluid loss, maintain system pressure, and ensure the efficient operation of various truck components 1.

Purpose of Hose Clamp 3016190 in Truck Operations

The Hose Clamp 3016190 plays a specific role in the operation of commercial trucks by securing hoses in various fluid systems. These systems include coolant, fuel, hydraulic, and pneumatic lines. By providing a secure connection, the clamp helps maintain the efficiency and reliability of these systems, which are crucial for the overall performance and safety of the truck.

Key Features of Hose Clamp 3016190

The Hose Clamp 3016190 is designed with several features that enhance its functionality. It is constructed from durable materials to withstand the rigors of truck operations. The clamp features a band type design, which allows for a snug fit around hoses of varying diameters. Additionally, it includes an adjustment mechanism that enables precise tightening, ensuring a secure connection without damaging the hose.

Benefits of Using Hose Clamp 3016190

Using the Hose Clamp 3016190 offers several advantages. Its durable construction ensures long-lasting performance, reducing the need for frequent replacements. The ease of installation allows for quick and efficient setup, minimizing downtime. Additionally, the reliable sealing provided by the clamp helps maintain secure connections, contributing to the overall efficiency and safety of the truck’s fluid systems.

Installation Procedures

To install the Hose Clamp 3016190, first, ensure the hose and fitting are clean and free of debris. Position the clamp around the hose and fitting, ensuring it is aligned correctly. Use the adjustment mechanism to tighten the clamp gradually, achieving a secure fit without over-tightening. Verify the connection by checking for leaks and ensuring the hose is not damaged.

Maintenance and Troubleshooting

Regular maintenance of the Hose Clamp 3016190 involves inspecting the clamp for signs of wear or corrosion. If any issues are detected, such as leaks or a loose connection, the clamp should be adjusted or replaced as necessary. Troubleshooting common issues may involve checking the alignment of the hose and fitting, ensuring the clamp is properly tightened, and verifying that the hose is in good condition.

Compatibility and Applications

The Hose Clamp 3016190 is designed for use in various commercial truck systems. It is compatible with a range of hose sizes and types, making it versatile for different applications. Typical uses include securing coolant, fuel, hydraulic, and pneumatic lines, ensuring the efficient operation of these systems.

Safety Considerations

When installing, maintaining, or troubleshooting the Hose Clamp 3016190, it is important to observe safety practices. Ensure the truck is turned off and the system is depressurized before beginning work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow manufacturer guidelines for installation and maintenance to ensure safe and effective use of the clamp.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of various industries, including transportation, construction, and agriculture.

Cummins Hose Clamp 3016190 Compatibility with Various Engine Models

The Cummins Hose Clamp part number 3016190 is designed to fit a variety of engine models, ensuring a secure and reliable connection for various hoses and lines. This clamp is engineered to meet the stringent requirements of heavy-duty applications, providing durability and ease of installation.

Cummins 4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, both part of Cummins’ lineup, benefit from the use of the 3016190 Hose Clamp. These engines are known for their robust performance and reliability in demanding environments. The clamp’s design allows for a tight seal, preventing leaks and ensuring the integrity of the engine’s cooling and fuel systems.

Cummins 6C8.3 and L10 MECHANICAL Engines

Similarly, the 6C8.3 and L10 MECHANICAL engines are compatible with the 3016190 Hose Clamp. These engines are utilized in various applications, from construction to agricultural machinery, where durability and performance are critical. The clamp’s compatibility with these engines ensures that hose connections remain secure under high-pressure and high-temperature conditions.

Cummins NH/NT 855 Engine

The NH/NT 855 engine, another robust Cummins model, is also designed to work with the 3016190 Hose Clamp. This engine is widely used in agricultural and industrial applications, where it is subjected to rigorous conditions. The clamp’s ability to maintain a tight seal is essential for the engine’s efficient operation and longevity.

Cummins QSK45 CM500 and QSK60 CM500 Engines

The QSK45 CM500 and QSK60 CM500 engines, known for their high power output and efficiency, are also compatible with the 3016190 Hose Clamp. These engines are used in a variety of applications, including marine and power generation. The clamp’s design ensures that hose connections remain secure, even in the most demanding environments.

Role of Part 3016190 Hose Clamp in Engine Systems

The part 3016190 Hose Clamp is an essential component in ensuring the secure and efficient operation of various engine systems. It plays a significant role in maintaining the integrity of connections within the engine’s plumbing and fluid systems. Here’s how it integrates with different components:

Breather and Crankcase Systems

In breather and crankcase systems, the Hose Clamp secures hoses that vent pressure and release contaminants. This ensures that the breather system functions correctly, allowing for the safe release of pressure without leaks, which could otherwise lead to engine inefficiency or damage.

Corrosion-Resistant Brackets and Mountings

When used with corrosion-resistant brackets and mountings, the Hose Clamp provides a reliable connection point for hoses that may be exposed to harsh environments. This is particularly important in marine or industrial applications where corrosion can quickly degrade unprotected components.

Engine Fittings and Installation Kits

Within engine fittings kits, the Hose Clamp is used to connect various hoses to fittings, ensuring a leak-free seal. This is vital during engine installation, where secure connections are necessary to prevent fluid leaks that could cause engine malfunction.

Muffler and Plumbing Systems

In muffler and plumbing systems, the Hose Clamp secures hoses that carry exhaust gases or coolant. This ensures that these systems operate under pressure without the risk of disconnection, which could lead to dangerous situations or reduced engine performance.

Aftercooler Water Systems

For aftercooler water systems, the Hose Clamp is used to connect hoses that circulate water through the aftercooler. This ensures efficient cooling of compressed air, which is essential for the performance and longevity of the engine.

Thermostat and Housing Connections

In thermostat and housing connections, the Hose Clamp secures hoses that regulate the flow of coolant. This is important for maintaining optimal engine temperature, ensuring that the engine operates within safe thermal limits.

Water Filter Systems

Finally, in water filter systems, the Hose Clamp connects hoses that transport water to and from the filter. This ensures that the filtration process is uninterrupted and that the engine receives clean water, which is crucial for its efficient operation and longevity.

Conclusion

The Hose Clamp 3016190 by Cummins is a versatile and reliable component that plays a crucial role in maintaining the integrity of fluid systems in commercial trucks. Its durable construction, ease of installation, and compatibility with various engine models make it an essential part for ensuring the efficient and safe operation of truck systems. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.