3026396

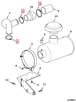

Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Hose Clamp 3026396 is a specialized component designed for use in commercial truck operations. Its primary function is to secure hoses within various truck systems, ensuring that connections remain tight and secure under operational conditions. The significance of this clamp lies in its ability to maintain the integrity of hose connections, which is vital for the efficient and safe operation of truck systems 1.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings. They play a role in preventing leaks and ensuring that fluid transfer systems operate efficiently. There are several types of hose clamps, including worm gear, spring, and screw-type clamps, each designed for specific applications based on the environment and type of hose being used 2.

Purpose of the Cummins Hose Clamp 3026396

The Cummins Hose Clamp 3026396 is specifically engineered to secure hoses in commercial truck applications. It is utilized in various truck systems, including fuel, coolant, and hydraulic systems. By providing a secure connection, this clamp helps maintain system pressure, prevent leaks, and ensure the reliable operation of these systems 3.

Key Features

The Cummins Hose Clamp 3026396 is constructed from high-quality materials, ensuring durability and resistance to corrosion. Its design includes features such as a robust band and a secure locking mechanism, which contribute to its effectiveness in clamping hoses tightly. Additionally, the clamp is designed to accommodate a range of hose sizes, making it versatile for various applications 4.

Benefits

Using the Cummins Hose Clamp 3026396 offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The clamp’s design allows for easy installation, minimizing downtime during maintenance procedures. Furthermore, its secure clamping mechanism ensures a reliable seal, preventing leaks and maintaining system efficiency 5.

Installation Process

Installing the Cummins Hose Clamp 3026396 involves several steps to ensure a secure fit. First, the hose should be properly aligned with the fitting. The clamp is then positioned around the hose and fitting, ensuring it is centered. Using the appropriate tool, the clamp is tightened until the desired tension is achieved, securing the hose in place. It is important to follow manufacturer guidelines for torque specifications to avoid over-tightening, which could damage the hose 6.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the clamp. To address leaks, first, ensure the clamp is properly tightened. If the issue persists, inspect the hose and fitting for damage. Replacing worn components can often resolve sealing problems 7.

Maintenance Tips

Regular maintenance of hose clamps is important for ensuring longevity and optimal performance. Inspections should be conducted periodically to check for signs of wear, corrosion, or damage. Clamps that show signs of deterioration should be replaced to prevent system failures. Additionally, ensuring that clamps are properly tightened during routine maintenance can help maintain secure connections 8.

Safety Considerations

When working with hose clamps, it is important to follow safety practices to prevent injuries and ensure effective operation. This includes using the correct size and type of clamp for the application, handling clamps with care to avoid injuries, and ensuring that all tools and equipment are in good working condition. Proper installation and maintenance of hose clamps are crucial for the safe and efficient operation of truck systems 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications 10.

Cummins Hose Clamp 3026396 Compatibility

The Cummins Hose Clamp part number 3026396 is a versatile component designed to fit a wide range of Cummins engines. This clamp is engineered to provide a secure and reliable seal for various hose connections, ensuring optimal performance and safety in engine operations.

Compatibility with Cummins Engines

QSB Series:

- QSB4.5 CM850 (CM2850)

- QSB5.9 30 CM550

- QSB5.9 44 CM550

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

ISM Series:

- ISM CM570

- ISM11 CM876 SN

ISB and ISC Series:

- ISB CM550

- ISC CM554

QSK Series:

- QSK19 CM850 MCRS

- QSK60 CM850 MCRS

QSC Series:

- QSC8.3 CM554

QSL Series:

- QSL8.9 CM2150 L141

- QSL9 CM850 (CM2850)

QSM Series:

- QSM11 CM570

Other Models:

- 4B3.9

- 6B5.9

- 6C8.3

- G5.9

- G855

- K19

- K50

- M11 CELECT PLUS

- M11 MECHANICAL

- V28

This hose clamp is designed to meet the rigorous demands of Cummins engines, providing a dependable solution for securing hoses in various engine configurations. Whether used in industrial, agricultural, or transportation applications, the 3026396 Hose Clamp ensures that hose connections remain tight and leak-free, contributing to the overall efficiency and longevity of the engine 11.

Role of Part 3026396 Hose Clamp in Engine Systems

The part 3026396 Hose Clamp is instrumental in ensuring the secure and reliable connection of various hoses within an engine system. Its application spans across multiple components, facilitating efficient operation and maintenance of the engine.

Aftercooler Plumbing

In the aftercooler plumbing system, the Hose Clamp secures hoses that transport cooled air from the aftercooler to the engine. This ensures a consistent and unimpeded airflow, which is essential for optimal engine performance and longevity 12.

Aid and Injection Starting Systems

For aid and injection starting systems, the Hose Clamp plays a role in maintaining the integrity of fuel and air lines. Secure connections prevent leaks and ensure that the correct mixture of fuel and air is delivered to the engine, promoting smooth starts and reliable operation 13.

Breather and Crankcase Systems

In breather and crankcase systems, the Hose Clamp is used to connect ventilation hoses. This helps in managing pressure within the crankcase and expelling contaminants, which is vital for maintaining engine health and performance 14.

Cleaner and Air Connection Systems

For cleaner and air connection systems, the Hose Clamp ensures that air intake hoses are firmly attached. This is important for drawing in the necessary amount of clean air for combustion, which directly impacts engine efficiency and emissions 15.

Air Crossover and Air Intake Connections

In air crossover and air intake connection systems, the Hose Clamp secures hoses that route air to different parts of the engine. Reliable connections here are essential for balanced air distribution and consistent engine performance 16.

Water Inlet and Water Outlet Connections

For water inlet and water outlet connections, the Hose Clamp is used to attach hoses that circulate coolant through the engine. This helps in regulating engine temperature, preventing overheating, and ensuring longevity 17.

Wet Exhaust Manifold and Heat Exchanger

In wet exhaust manifold and heat exchanger systems, the Hose Clamp secures hoses that manage the flow of coolant and exhaust gases. This is important for efficient heat exchange and maintaining optimal operating temperatures 18.

Exhaust Cooler Leak Test Kit and Front Water Cross Connection

For exhaust cooler leak test kits and front water cross connections, the Hose Clamp ensures that test and operational hoses are securely attached. This is vital for accurate leak detection and reliable coolant flow 19.

Hardware Certification Kit and Housing Thermostat Module

In hardware certification kits and housing thermostat modules, the Hose Clamp is used to connect hoses that facilitate testing and temperature regulation. Secure connections here ensure accurate readings and efficient thermostat operation 20.

Fuel Control and Mounting Breather

For fuel control and mounting breather systems, the Hose Clamp secures hoses that manage fuel delivery and ventilation. This is important for precise fuel control and maintaining a stable engine environment 21.

Plumbing and Sea Water Piping

In plumbing and sea water piping systems, the Hose Clamp ensures that hoses carrying sea water for cooling purposes are firmly attached. This is essential for efficient cooling and preventing corrosion 22.

Torque Converter Oil, Dipstick, Fill & Breather, and T.C. Cooler

For torque converter oil, dipstick, fill & breather, and T.C. cooler systems, the Hose Clamp secures hoses that manage oil flow and ventilation. This ensures proper lubrication, accurate oil level readings, and efficient cooling of the torque converter 23.

Turbocharger Mounting and Water Bypass Assembly Tee

In turbocharger mounting and water bypass assembly tee systems, the Hose Clamp is used to connect hoses that manage air and coolant flow. This is important for efficient turbocharger operation and maintaining optimal engine temperatures 24.

Water Manifold

Finally, in water manifold systems, the Hose Clamp ensures that hoses distributing coolant to various engine components are securely attached. This is vital for uniform coolant distribution and consistent engine temperature regulation 25.

Conclusion

The Cummins Hose Clamp 3026396 is a critical component in ensuring the secure and reliable operation of various hose connections within commercial truck and engine systems. Its durable construction, versatile design, and ease of installation make it an essential part for maintaining system integrity and efficiency. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 5659625.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.