This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

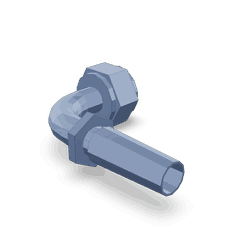

The Hose Swivel 3034136, manufactured by Cummins, is a critical component in the commercial truck industry. Designed for fluid transfer in various systems, this swivel ensures efficient and uninterrupted operation in dynamic truck environments.

Basic Concepts of Hose Swivels

A hose swivel allows for the rotation of a hose while maintaining continuous fluid flow. It is essential in fluid transfer systems where hose movement or rotation is necessary. The swivel mechanism, with internal seals and bearings, enables rotation while preventing leaks, ensuring the hose can move freely in applications where static connections are impractical 1.

Purpose of Hose Swivel 3034136 in Truck Operations

This Cummins part facilitates fluid transfer in systems requiring movement or rotation, such as fuel, hydraulic, and cooling systems. By allowing hose swiveling, it accommodates the dynamic movements of the truck, ensuring consistent fluid flow, which is vital for system reliability 2.

Key Features of Hose Swivel 3034136

The 3034136 is constructed from durable materials to withstand commercial truck environments. Its swivel mechanism provides smooth rotation and is equipped with high-quality seals to prevent leaks. It also features robust connection types for a secure fit with the hose and other system components 3.

Benefits of Using Hose Swivel 3034136

Incorporating this part into truck systems offers several advantages. Its flexibility allows for greater hose movement and rotation, crucial in dynamic truck applications. The durable construction ensures long-lasting performance, reducing the need for frequent replacements. Additionally, efficient fluid transfer capabilities contribute to the overall reliability and efficiency of the truck’s systems.

Installation Considerations

Proper installation of the Hose Swivel 3034136 is vital for optimal performance and longevity. It is important to follow manufacturer guidelines for torque specifications and connection procedures. Ensuring all connections are secure and the swivel is properly aligned will help prevent leaks and maintain efficient fluid transfer. Regular inspections during installation can also help identify potential issues before they become problematic.

Maintenance and Troubleshooting

Maintaining the Hose Swivel 3034136 involves regular inspections for signs of wear, leaks, or damage. Cleaning the swivel and its connections can help prevent buildup that may affect performance. If issues are detected, such as leaks or restricted flow, troubleshooting steps may include checking the seals, bearings, and connections for proper function. Addressing these issues promptly can help maintain the efficiency and reliability of the truck’s fluid transfer systems.

Safety Precautions

When working with the Hose Swivel 3034136, it is important to observe several safety precautions to prevent accidents and ensure safe operation. This includes wearing appropriate personal protective equipment, ensuring that the truck is properly shut down and secured before beginning work, and following all manufacturer safety guidelines. Additionally, being aware of the potential hazards associated with fluid transfer systems, such as leaks or pressurized fluids, can help prevent injuries.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a strong reputation for quality, innovation, and reliability in the commercial truck industry. Their product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications.

Cummins Hose Swivel Part 3034136 Compatibility

The Cummins Hose Swivel part number 3034136 is a versatile component designed to fit a variety of Cummins engines. This part is essential for ensuring smooth and reliable operation of the engine’s hydraulic and fuel systems by allowing hoses to rotate freely without kinking or restricting flow.

ISM Series Engines

The ISM CM570, ISM CM570/870, ISM CM876, ISX CM570, and QSM11 CM570 engines all benefit from the use of the Hose Swivel part 3034136. These engines are commonly used in heavy-duty applications, including trucks and industrial machinery, where durability and performance are critical.

K Series Engines

The K19, K38, and K50 engines are part of Cummins’ K Series, which are known for their reliability and efficiency in medium-duty applications. The Hose Swivel part 3034136 is compatible with these engines, ensuring that the hydraulic and fuel systems operate smoothly under various conditions.

L10 Series Engines

The L10 CELECT, L10 MECHANICAL, M11 CELECT, M11 CELECT PLUS, and M11 MECHANICAL engines are designed for both light and medium-duty applications. The Hose Swivel part 3034136 fits these engines, providing the necessary flexibility for hoses to move freely and maintain optimal performance.

N14 Series Engines

The N14 CELECT, N14 CELECT PLUS, and N14 MECHANICAL engines are part of Cummins’ N Series, which are widely used in heavy-duty applications such as trucks and construction equipment. The Hose Swivel part 3034136 is compatible with these engines, ensuring that the hydraulic and fuel systems function efficiently.

QSK Series Engines

The QSK19 CM2350 K114, QSK19 CM500, QSK19 CM850 MCRS, QSK19G, QSK45 CM500, QSK60 CM500, QSK60G, and QSK78 CM500 engines are part of Cummins’ QSK Series, which are designed for high-performance applications. The Hose Swivel part 3034136 is compatible with these engines, providing the necessary flexibility for hoses to rotate freely and maintain optimal performance.

Role of Part 3034136 Hose Swivel in Engine Systems

The Part 3034136 Hose Swivel is an integral component in various engine systems, facilitating the efficient transfer of fluids and gases while accommodating the dynamic movements of connected parts. Its application spans across several key systems within an engine, enhancing functionality and reliability.

Fuel System Integration

In the fuel system, the Hose Swivel connects the fuel filter to the fuel pump fitting, ensuring a secure and flexible link. This allows for the smooth flow of fuel from the filter to the pump, accommodating the vibrations and movements inherent in engine operation. The swivel’s design prevents kinking and stress on the hose, maintaining consistent fuel delivery.

Engine Control Module and Plumbing

The Hose Swivel plays a significant role in the engine control module (ECM) plumbing by connecting various sensors and actuators to the ECM. This ensures that the ECM receives accurate data from sensors and can effectively control actuators, optimizing engine performance. The swivel’s flexibility is essential in managing the spatial constraints and movements within the engine compartment.

Crankcase Breather and Ventilation

In the crankcase breather system, the Hose Swivel connects the breather to the intake tract or atmosphere. This connection allows for the safe release of gases from the crankcase, preventing pressure build-up and ensuring the engine operates within safe parameters. The swivel’s ability to rotate and flex accommodates the engine’s natural movements, enhancing the breather system’s efficiency.

Cooling System

Within the cooling system, the Hose Swivel is used to connect the cooler plate to the engine’s coolant passages. This ensures efficient heat exchange and coolant flow, vital for maintaining optimal engine temperature. The swivel’s design allows for the necessary flexibility to handle the thermal expansion and contraction of the engine components.

Drive and Fan Arrangements

In drive and fan arrangements, the Hose Swivel is employed to connect the fan drive arrangement to the fan hub mounting. This ensures that the fan operates efficiently, drawing air through the radiator and cooling the engine. The swivel’s flexibility accommodates the rotational and vibrational movements of the fan, enhancing the durability and performance of the cooling system.

Fuel and Prelub Plumbing

The Hose Swivel is also integral in fuel and prelub plumbing, connecting the fuel filter hose to the fuel plumbing and the prelub plumbing to various engine components. This ensures a consistent supply of fuel and lubricants, critical for engine start-up and operation. The swivel’s design prevents leaks and maintains the integrity of the plumbing system under dynamic conditions.

Float Tank and Plumbing

In float tank systems, the Hose Swivel connects the float tank plumbing to the engine’s fuel system. This ensures a steady supply of fuel to the engine, accommodating the movements and vibrations of the engine components. The swivel’s flexibility is essential in maintaining a reliable fuel supply, especially in applications where the engine undergoes significant movement.

Primer and Fuel System

The Hose Swivel is used in the primer and fuel system to connect the priming pump to the fuel filter and fuel lines. This ensures that the fuel system is primed correctly, facilitating easy engine start-up. The swivel’s design allows for the necessary flexibility to handle the pressure changes and movements during the priming process.

Conclusion

The Part 3034136 Hose Swivel is a versatile component that enhances the functionality and reliability of various engine systems by providing flexible and secure connections. Its ability to accommodate dynamic movements and vibrations makes it an essential part in maintaining efficient fluid and gas transfer within the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.