This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Hose Clamp 3041617 is a specialized component designed for use in commercial trucks. Its primary function is to secure hoses within various truck systems, ensuring that connections remain tight and secure under operational conditions. This clamp plays a role in maintaining the integrity of fluid transfer systems, contributing to the overall efficiency and reliability of the vehicle 3.

Basic Concepts of Hose Clamps

Hose clamps are devices used to create a secure connection between a hose and a fitting. They are integral in various systems within a truck, including fuel, coolant, and hydraulic systems. By applying pressure around the hose, these clamps prevent leaks and ensure that fluids are transferred efficiently and safely. Their role is fundamental in maintaining the operational integrity of these systems 4.

Purpose of the Cummins Hose Clamp 3041617

The Cummins Hose Clamp 3041617 is specifically designed to secure hoses in commercial truck applications. It is utilized in different truck systems where secure hose connections are required. This includes but is not limited to, fuel lines, coolant systems, and hydraulic circuits. The clamp ensures that hoses remain firmly attached to their fittings, preventing leaks and maintaining system pressure 1.

Key Features

The Cummins Hose Clamp 3041617 boasts several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design of the clamp allows for easy installation and adjustment, providing a secure fit on a variety of hose sizes. Additionally, its unique attributes, such as a durable band and precise screw mechanism, contribute to its effectiveness in demanding truck environments 2.

Benefits of Using Cummins Hose Clamp 3041617

Utilizing the Cummins Hose Clamp 3041617 offers several advantages. Its robust construction and design contribute to improved reliability, reducing the likelihood of leaks and system failures. The ease of installation saves time during maintenance procedures, and its durability leads to long-term cost savings by minimizing the need for frequent replacements 3.

Installation Process

Installing the Cummins Hose Clamp 3041617 requires attention to detail to ensure a secure fit. The process involves positioning the clamp around the hose and fitting, then using the provided tool to tighten the screw mechanism until the desired pressure is achieved. It is important to follow best practices, such as ensuring the clamp is centered on the hose and not over-tightening, to avoid damaging the hose or fitting 4.

Troubleshooting Common Issues

Common issues with hose clamps, such as leaks or improper sealing, can often be traced back to incorrect installation or wear and tear. Troubleshooting steps include inspecting the clamp for proper positioning and tightness, checking the condition of the hose and fitting for damage, and replacing the clamp if necessary to restore a secure connection 1.

Maintenance Tips

Regular maintenance of the Cummins Hose Clamp 3041617 is key to ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or corrosion, and replacement according to the manufacturer’s guidelines or when signs of degradation are observed. Proper maintenance helps prevent unexpected failures and ensures the continued efficiency of the truck’s systems 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial vehicle operators worldwide 3.

Compatibility with Engine Models

The Cummins Hose Clamp 3041617 is designed to fit seamlessly with various engine models, ensuring a secure and reliable connection for fluid and gas lines. This part is integral to maintaining the integrity of the engine’s systems, preventing leaks and ensuring optimal performance.

N14 CELECT and N14 MECHANICAL Engines

For the N14 CELECT and N14 MECHANICAL engines, the Hose Clamp 3041617 is specifically engineered to fit the critical points where hoses connect to the engine. These engines, known for their robust design and high performance, require precise fittings to handle the pressures and temperatures they operate under. The clamp ensures that the connections remain tight and secure, even under the most demanding conditions 4.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the use of the Cummins Hose Clamp 3041617. These engines are designed for heavy-duty applications, and the hose clamp plays a role in maintaining the efficiency and reliability of the engine’s fluid systems. The clamp’s design allows for easy installation and removal, facilitating maintenance and repairs 1.

Installation and Maintenance

When installing the Hose Clamp 3041617 on any of these engines, it is essential to follow the manufacturer’s guidelines to ensure a proper fit. Regular inspection and replacement of the clamp as needed are important to maintaining the engine’s performance and longevity. The clamp’s material and construction are designed to withstand the harsh environments within the engine compartment, providing a durable solution for securing hoses 2.

Role of Part 3041617 Hose Clamp in Engine Systems

The part 3041617 Hose Clamp is a component in ensuring the secure attachment and reliable performance of hoses within engine systems. Specifically, it plays a role in the following components:

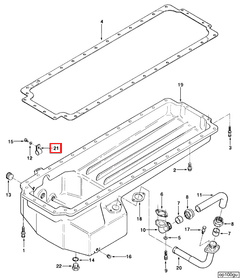

Oil Pan and Pan

In engine systems, the oil pan serves as a reservoir for engine oil, which is vital for lubricating moving parts and reducing friction. The hoses connected to the oil pan facilitate the circulation of oil to and from various engine components. The 3041617 Hose Clamp ensures that these hoses are firmly attached to the oil pan, preventing leaks and maintaining the integrity of the oil circulation system. This secure attachment is important for consistent oil flow, which is necessary for the proper lubrication of engine parts and the overall efficiency of the engine 3.

Similarly, in systems where additional pans are used for oil storage or as part of an oil scavenging system, the 3041617 Hose Clamp ensures that hoses connecting these pans are securely fastened. This prevents oil leaks and ensures that the scavenging system effectively collects and returns oil to the sump, maintaining optimal oil levels and engine performance 4.

Conclusion

The Cummins Hose Clamp 3041617 is a vital component in the maintenance and operation of commercial truck systems. Its design and features contribute to the reliability and efficiency of fluid transfer systems, ensuring secure hose connections and preventing leaks. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ultimately contributing to the overall performance and longevity of the vehicle.

-

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩ ↩ ↩ -

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ ↩ ↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ ↩ ↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.