This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

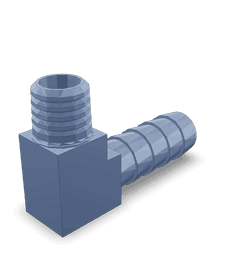

The Elbow Hose Coupling part #3045178, manufactured by Cummins, is a component designed for use in commercial truck systems. It plays a role in maintaining efficient fluid transfer within the vehicle by facilitating the connection of hoses at an angle. This part is integral to ensuring that fluids such as coolant, fuel, and hydraulic fluid are transferred smoothly and effectively throughout the truck’s system 1.

Basic Concepts of Elbow Hose Coupling

An Elbow Hose Coupling is a fitting used to join two hoses at an angle, allowing for fluid flow between them. This type of coupling is particularly useful in systems where space is limited or where the routing of hoses requires changes in direction. By connecting hoses at an angle, the Elbow Hose Coupling helps to maintain a consistent flow of fluid, reducing the risk of leaks and ensuring that the system operates efficiently 2.

Purpose of the 3045178 Elbow Hose Coupling

The 3045178 Elbow Hose Coupling is designed to aid in the transfer of various fluids within a truck’s system. Its primary function is to connect hoses at an angle, which is often necessary in the compact and complex environments found in commercial trucks. This coupling ensures that fluids such as coolant, fuel, or hydraulic fluid can flow smoothly from one part of the system to another, supporting the overall performance and reliability of the truck 3.

Key Features

The 3045178 Elbow Hose Coupling boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring long-lasting use in demanding environments. The design of the coupling includes precise angles and fittings that allow for a secure connection between hoses, minimizing the risk of leaks. Additionally, the coupling is engineered to withstand high pressure and temperature variations, making it suitable for use in a variety of truck systems 4.

Benefits

Using the 3045178 Elbow Hose Coupling in truck systems offers several benefits. It improves fluid flow efficiency by providing a smooth and angled connection between hoses, which can help to reduce turbulence and pressure drops. The durable construction of the coupling ensures that it can withstand the rigors of commercial truck operation, leading to a longer service life. Additionally, the design of the coupling allows for ease of installation, reducing downtime during maintenance procedures.

Installation Process

Installing the 3045178 Elbow Hose Coupling requires careful attention to detail to ensure a proper fit and secure connection. Begin by ensuring that the hoses to be connected are clean and free of any debris. Align the coupling with the hoses, making sure that the angled fittings match the required direction of fluid flow. Use the appropriate tools to tighten the coupling, ensuring that it is secure but not overtightened, which could damage the hoses or the coupling itself. Following the manufacturer’s guidelines for torque specifications is recommended to achieve the best results.

Troubleshooting and Maintenance

Common issues with the 3045178 Elbow Hose Coupling may include leaks at the connection points or difficulty in maintaining a secure fit. To troubleshoot these issues, first, check for any signs of wear or damage on the coupling or hoses. Ensure that the coupling is properly aligned and tightened according to the manufacturer’s specifications. Regular maintenance, such as inspecting the coupling for signs of wear and ensuring that all connections are secure, can help to prevent issues and ensure the longevity of the part.

Compatibility and Applications

The 3045178 Elbow Hose Coupling is designed for use in a variety of commercial truck systems, where it plays a role in connecting hoses at an angle to facilitate fluid flow. Its applications include coolant systems, fuel lines, and hydraulic systems, among others. The coupling is compatible with a range of truck makes and models, making it a versatile component for fleet maintenance and repair.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industries. The company’s expertise in manufacturing components like the 3045178 Elbow Hose Coupling reflects its dedication to providing reliable and high-performance parts for commercial vehicles.

Compatibility of Elbow Hose Coupling Part 3045178 with Cummins Engines

The Elbow Hose Coupling part number 3045178, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is integral in ensuring the proper connection and functionality of hoses within the engine’s system, facilitating the smooth transfer of fluids and gases.

C GAS PLUS CM556 and C8.3 G Engines

The C GAS PLUS CM556 and C8.3 G engines are part of Cummins’ lineup of smaller, yet robust engines. The 3045178 coupling is engineered to fit these engines, providing a reliable connection point for hoses that are critical for the engine’s operation. This ensures that the fluid dynamics within these engines are maintained, contributing to their overall efficiency and longevity.

G8.3 and ISM CM570 Engines

Moving to the G8.3 and ISM CM570 engines, which are known for their power and reliability in various applications, the 3045178 coupling plays a role. These engines require precise connections for their fluid systems, and the coupling’s design ensures that these connections are both secure and durable. This is particularly important in the ISM CM570, where the coupling’s fit is critical for maintaining the engine’s performance under various conditions.

ISX12 G CM2180 EJ and L10 MECHANICAL Engines

The ISX12 G CM2180 EJ and L10 MECHANICAL engines represent a blend of advanced technology and mechanical reliability. The 3045178 coupling is designed to integrate with these engines, providing a critical link in the hose systems that are essential for the engines’ operation. This ensures that the fluid and gas transfer within these engines is efficient and reliable, supporting their performance in demanding environments.

M11 CELECT, M11 CELECT PLUS, M11 MECHANICAL, and QSM11 CM570 Engines

The M11 CELECT, M11 CELECT PLUS, M11 MECHANICAL, and QSM11 CM570 engines are part of Cummins’ M11 series, known for their versatility and efficiency. The 3045178 coupling is specifically designed to fit these engines, ensuring that the hose connections are secure and efficient. This is particularly important in the M11 CELECT PLUS and QSM11 CM570, where the coupling’s design supports the advanced features of these engines, contributing to their overall performance and reliability.

Each of these engines, with their unique characteristics and applications, benefits from the precise fit and functionality of the 3045178 Elbow Hose Coupling. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance the performance and durability of their engines.

Role of Part 3045178 Elbow Hose Coupling in Engine Systems

The 3045178 Elbow Hose Coupling is an essential component in various engine systems, facilitating the secure and efficient transfer of fluids and gases. Its application spans across multiple subsystems, ensuring optimal performance and reliability.

Aftercooler Plumbing

In the aftercooler plumbing system, the 3045178 Elbow Hose Coupling is utilized to connect hoses that transport cooled air from the aftercooler to the engine intake. This connection ensures a leak-free pathway, maintaining the efficiency of the air cooling process and preventing any loss of pressure that could affect engine performance.

Fuel Control Module and Fuel Control Plumbing

When integrated into the fuel control module and its associated plumbing, the 3045178 Elbow Hose Coupling plays a role in directing fuel lines. It ensures that fuel is delivered consistently and without interruption to the engine components, which is vital for maintaining precise fuel-to-air ratios and overall engine efficiency.

Oil Cooler Water Plumbing

In oil cooler water plumbing systems, the 3045178 Elbow Hose Coupling is employed to connect hoses that circulate water through the oil cooler. This setup helps in dissipating heat from the engine oil, ensuring that the oil remains within optimal temperature ranges for lubrication and performance.

Turbocharger and Turbocharger Plumbing

For turbochargers and their plumbing systems, the 3045178 Elbow Hose Coupling is used to connect various hoses that manage the flow of exhaust gases and pressurized air. This connection is key to maintaining the integrity of the turbocharger system, ensuring that boost pressure is delivered efficiently to the engine intake.

Resistor and Corrosion Considerations

In systems where resistors are used to manage electrical flows or where corrosion is a concern, the 3045178 Elbow Hose Coupling provides a robust connection that resists environmental factors. Its material properties help in minimizing corrosion, ensuring long-term reliability in harsh operating conditions.

Overall, the 3045178 Elbow Hose Coupling is a versatile component that enhances the functionality and durability of various engine systems by providing secure, leak-free connections.

Conclusion

The 3045178 Elbow Hose Coupling by Cummins is a critical component in the efficient operation of commercial truck systems. Its design and construction ensure reliable fluid transfer, contributing to the overall performance and longevity of the vehicle. Proper installation, maintenance, and understanding of its applications are key to maximizing the benefits of this part in various engine systems.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines. McGraw-Hill, 2008.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.