This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Elbow Hose Coupling, part #3056686, manufactured by Cummins, is a component designed for use in commercial trucks. It is integral to the fluid systems within these vehicles, contributing to their overall efficiency and reliability. This coupling facilitates the connection between hoses at an angle, allowing for flexible routing of fluids within the truck’s systems.

Basic Concepts of Elbow Hose Couplings

An Elbow Hose Coupling is a fitting used to join two hoses at an angle, typically 90 degrees. Its function in fluid systems is to provide a secure and leak-proof connection that can accommodate changes in direction. These couplings operate by compressing the hose ends within the coupling body, creating a seal that prevents fluid leakage. Common materials used in their construction include rubber for the hoses and metal or high-strength polymers for the coupling body, ensuring durability and resistance to various fluids and environmental conditions 1.

Purpose of the 3056686 Elbow Hose Coupling in Truck Operations

The 3056686 Elbow Hose Coupling plays a role in the operation of commercial trucks by facilitating the connection of hoses in systems where space constraints or routing requirements necessitate a change in direction. It is part of various fluid systems, including coolant, fuel, and hydraulic systems, contributing to their efficient functioning by ensuring a reliable connection that can withstand the pressures and temperatures of these systems.

Key Features of the 3056686 Elbow Hose Coupling

The 3056686 Elbow Hose Coupling features a design that allows for easy installation and removal without the need for specialized tools. It is constructed from materials that offer high resistance to corrosion and wear, enhancing its performance and durability. Unique attributes include a sealing mechanism that adapts to the hose material, ensuring a secure fit and preventing leaks.

Benefits of Using the 3056686 Elbow Hose Coupling

Incorporating the 3056686 Elbow Hose Coupling into truck systems offers several advantages. It improves fluid flow by providing a smooth transition between hoses, reducing the risk of blockages or restrictions. Its durability ensures long-term reliability, while its design facilitates ease of installation. Additionally, the coupling’s construction allows for straightforward maintenance, reducing downtime and repair costs.

Installation Considerations

When installing the 3056686 Elbow Hose Coupling, it is important to follow guidelines to ensure optimal performance. This includes using the proper torque settings to secure the coupling without overtightening, which could damage the hose or the coupling. Alignment procedures should be carefully followed to ensure the hoses are correctly positioned, allowing for efficient fluid flow and minimizing stress on the connection.

Troubleshooting Common Issues

Common problems associated with Elbow Hose Couplings include leaks, connection failures, and material wear. Troubleshooting steps may involve inspecting the coupling for signs of damage or wear, ensuring the hoses are correctly seated within the coupling, and checking for proper alignment and torque settings. Addressing these issues promptly can prevent more significant problems and ensure the continued efficient operation of the truck’s fluid systems.

Maintenance Tips

Regular maintenance of the 3056686 Elbow Hose Coupling is key to ensuring its longevity and reliable performance. This includes periodic inspection for signs of wear or damage, cleaning the coupling and surrounding areas to prevent debris buildup, and checking the torque settings to ensure the connection remains secure. Replacement should be considered if significant wear is observed or if the coupling fails to create a secure seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality is evident in its manufacturing processes and the durability of its products, including the 3056686 Elbow Hose Coupling.

Engine Compatibility with Elbow Hose Coupling Part 3056686

The Elbow Hose Coupling part 3056686, manufactured by Cummins, is designed to integrate seamlessly with various engine models. This part is crucial for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Elbow Hose Coupling part 3056686 is utilized to connect the hoses that manage the flow of coolant and exhaust gases. Its design ensures a secure and leak-proof connection, which is essential for maintaining optimal engine performance and preventing overheating.

NH/NT 855

Similarly, in the NH/NT 855 engines, the part 3056686 plays a vital role in the engine’s fluid management system. This coupling is engineered to withstand the high pressures and temperatures typical of these engines, ensuring durability and reliability over time. Its precise fit and robust construction make it an ideal choice for maintaining the efficiency of the engine’s cooling and exhaust systems.

By integrating the Elbow Hose Coupling part 3056686 into these engines, Cummins ensures that the fluid pathways remain intact, thereby contributing to the overall longevity and efficiency of the engine.

Role of Part 3056686 Elbow Hose Coupling in Engine Systems

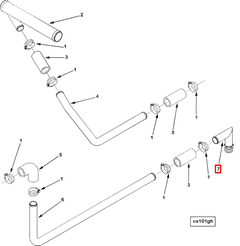

The 3056686 Elbow Hose Coupling is instrumental in facilitating the connection and redirection of fluid pathways within various engine systems. In the context of coolant heater plumbing, this component ensures a secure and efficient transition between different sections of the coolant lines, allowing for the smooth circulation of coolant to maintain optimal engine temperature.

When integrated into general plumbing systems within the engine, the 3056686 Elbow Hose Coupling provides a necessary change in direction for hoses, which is often required to navigate the compact and intricate layout of engine compartments. This adaptability helps in reducing the risk of kinks or stress on the hoses, thereby enhancing the durability and reliability of the plumbing system.

In the coolant heater starting aid system, the coupling plays a significant role by connecting the coolant heater to the main coolant lines. This connection is essential for preheating the engine coolant, which aids in quicker engine warm-up and improves overall engine performance, especially in colder climates.

Additionally, within the supply tube network, the 3056686 Elbow Hose Coupling allows for a precise and reliable connection point. This is particularly important in systems where the supply tube needs to change direction to reach its destination, ensuring that the fluid flow remains uninterrupted and efficient.

Conclusion

The 3056686 Elbow Hose Coupling by Cummins is a critical component in the fluid systems of commercial trucks, offering durability, ease of installation, and reliable performance. Its role in facilitating fluid flow and maintaining system integrity underscores its importance in the efficient operation of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.