This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3092094 Flexible Hose is a critical component in commercial truck systems, designed to facilitate the transfer of various fluids between different parts of the truck’s system. This hose is essential for maintaining the efficiency and reliability of the truck’s operations.

Basic Concepts of Flexible Hoses

Flexible hoses are widely used in automotive and heavy-duty truck systems to connect components requiring fluid transfer. Unlike rigid pipes, flexible hoses can accommodate movement and vibration, reducing stress on connected parts. They are typically made from materials that offer flexibility, durability, and resistance to the fluids they transport 1.

Purpose of the Cummins 3092094 Flexible Hose

The Cummins 3092094 Flexible Hose is designed to connect various systems within a truck, such as the fuel, coolant, or hydraulic systems. It transports fluids between these systems, ensuring that each component receives the necessary fluid for operation. This hose plays a role in maintaining the fluid dynamics within the truck, contributing to its overall performance and longevity 2.

Key Features

The Cummins 3092094 Flexible Hose is constructed from high-quality materials that provide flexibility and durability. Its design allows it to withstand the pressures and temperatures associated with truck operations. Additionally, its flexibility helps in accommodating the movement and vibrations typical in a truck’s environment 3.

Benefits

The use of the Cummins 3092094 Flexible Hose offers several advantages. Its flexibility reduces the stress on connected components compared to rigid pipes, potentially leading to a longer lifespan for the connected parts and the hose itself. Moreover, the hose’s durable construction ensures it can withstand harsh operating conditions, contributing to the truck’s reliability 4.

Installation Considerations

When installing the Cummins 3092094 Flexible Hose, it is important to follow guidelines to ensure proper fitment and function. This includes aligning the hose correctly with the connection points, securing it in place to prevent movement, and ensuring it fits within the truck’s system without kinks or excessive bends. Proper installation contributes to the hose’s effectiveness and longevity 5.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these, regular inspections are recommended to identify any signs of wear or damage. If a leak is detected, the source should be located and repaired or replaced as necessary. Kinks can often be resolved by repositioning the hose, and degraded sections may require replacement to maintain system integrity 6.

Maintenance Tips

Maintaining the Cummins 3092094 Flexible Hose involves regular inspections to check for signs of wear, such as cracks, leaks, or softening of the material. It is also important to ensure that the hose remains properly aligned and secured. Replacement should be considered if significant wear is observed, to prevent potential failures and ensure the continued reliability of the truck’s system 7.

Safety Precautions

When working with the Cummins 3092094 Flexible Hose, observing safety measures is important. This includes using appropriate protective equipment when handling the hose, especially when it is under pressure or contains hazardous fluids. In the event of a failure or leak, having an emergency response plan in place can help mitigate risks and ensure safety 8.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of products including engines, filtration systems, and components like the Cummins 3092094 Flexible Hose. The company has a reputation for quality and reliability, backed by a history of innovation and commitment to customer satisfaction 9.

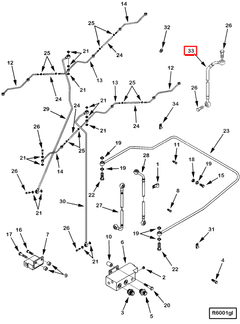

Role of Part 3092094 Flexible Hose in Fuel Plumbing Systems

The part 3092094 Flexible Hose is an essential component in fuel plumbing systems, facilitating the transfer of fuel from the tank to the engine and other related components. Its primary function is to provide a durable and flexible connection that can withstand the dynamic movements and vibrations inherent in engine operations.

Fuel Tank to Fuel Pump

In the pathway from the fuel tank to the fuel pump, the 3092094 Flexible Hose ensures a secure and leak-free connection. This hose is designed to handle the pressure variations and fuel flow rates, maintaining consistent fuel delivery to the pump. Its flexibility accommodates the movements of the vehicle, reducing the risk of wear and tear on the connections 10.

Fuel Pump to Fuel Injectors

Between the fuel pump and the fuel injectors, the 3092094 Flexible Hose plays a significant role in maintaining fuel pressure and flow. It connects the high-pressure fuel lines, ensuring that fuel is delivered efficiently to the injectors. The hose’s material is resistant to fuel degradation, ensuring longevity and reliable performance 11.

Fuel Return Line

In systems with a fuel return line, the 3092094 Flexible Hose is used to connect the fuel injectors back to the fuel tank. This setup allows excess fuel to be returned to the tank, maintaining system pressure and ensuring that the fuel pump operates within its optimal range. The hose’s flexibility is vital in this application, as it must endure continuous cycles of pressurization and decompression 12.

Auxiliary Fuel Systems

For vehicles equipped with auxiliary fuel systems, such as those found in performance or racing applications, the 3092094 Flexible Hose is often employed to connect additional fuel pumps, filters, or regulators. Its robust construction and flexibility make it suitable for high-performance environments where fuel demand and system pressures are significantly higher 13.

Emission Control Systems

In modern vehicles, fuel plumbing also integrates with emission control systems. The 3092094 Flexible Hose may be used in connections to the evaporative emission control system, ensuring that fuel vapors are properly managed and routed back into the fuel tank or combustion process. This application highlights the hose’s role in not only fuel delivery but also in contributing to overall vehicle emissions compliance 14.

Fuel Filter Connections

The hose is also utilized in connecting the fuel filter to the fuel lines. This ensures that fuel is adequately filtered before reaching the engine, preventing contaminants from causing damage to the fuel injectors and other sensitive components. The flexibility of the hose allows for easy installation and maintenance of the fuel filter 15.

Conclusion

The Cummins 3092094 Flexible Hose is a versatile and reliable component in fuel plumbing systems, ensuring efficient and safe fuel transfer across various connections and applications. Its design and material are chosen to withstand the operational conditions of these engines, ensuring durability and performance.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2250 B131. Bulletin Number 4388775.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2250 B131. Bulletin Number 4388775.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSB4.5 CM2250 B131. Bulletin Number 4388775.

↩ -

Richards, P., & Barker, J. (2023). Automotive Fuels Reference Book. SAE International.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.