This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Elbow Hose Coupling Assembly, identified by part number 3099932, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This assembly is integral to the fluid transfer systems in commercial trucks, ensuring efficient and reliable operation. Cummins is renowned for its commitment to quality and innovation in engine and component manufacturing, making this part a valuable addition to any truck’s system 1.

Basic Concepts

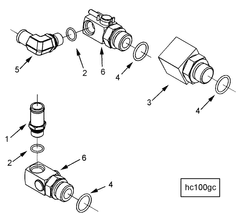

An Elbow Hose Coupling Assembly is a fitting used to connect hoses at an angle, facilitating the transfer of fluids such as coolant, fuel, or hydraulic fluid within a truck’s system. This assembly typically consists of a metal or plastic elbow, hose connectors, and seals. Its design allows for a secure and leak-proof connection, accommodating the angular orientation required in various truck systems 2.

Purpose and Role in Truck Operation

The Elbow Hose Coupling Assembly plays a significant role in the operation of a truck by enabling the transfer of fluids between components at an angle. This is particularly important in systems where space constraints or the layout of the truck necessitates angled connections. By providing a reliable connection point, it ensures that fluids are transferred efficiently without leaks, contributing to the overall performance and safety of the truck 3.

Key Features

The 3099932 Elbow Hose Coupling Assembly features a robust design that includes high-quality materials such as durable plastics or metals for the elbow and connectors. It is engineered to withstand the pressures and temperatures associated with truck fluid systems. Additionally, the assembly incorporates precision-machined fittings and high-performance seals to ensure a secure and leak-proof connection. Its design also allows for easy installation and maintenance, enhancing its practicality in commercial truck applications.

Benefits

The benefits of using the 3099932 Elbow Hose Coupling Assembly include improved efficiency in fluid transfer systems, enhanced durability under demanding conditions, and increased reliability. Its robust construction and precise engineering contribute to a longer service life, reducing the need for frequent replacements. Moreover, the secure connection it provides minimizes the risk of leaks, which can lead to system failures or inefficiencies.

Installation Process

Installing the Elbow Hose Coupling Assembly involves several steps to ensure a proper and secure fit. Begin by identifying the correct orientation of the elbow to match the truck’s system layout. Prepare the hoses by cleaning the ends and applying the appropriate lubricant to facilitate connection. Carefully insert the hoses into the coupling, ensuring they are fully seated. Tighten the connectors according to the manufacturer’s specifications to achieve a secure seal. It is important to avoid over-tightening, which can damage the fittings or seals.

Troubleshooting Common Issues

Common issues with the Elbow Hose Coupling Assembly may include leaks, difficulty in connection, or damage to the fittings. To address leaks, first, ensure that the hoses are properly seated and the connectors are tightened to the correct torque. If leaks persist, inspect the seals for damage and replace if necessary. Difficulty in connection may be resolved by ensuring the hoses are clean and lubricated. Damaged fittings should be replaced to maintain the integrity of the fluid transfer system.

Maintenance Tips

Regular maintenance of the Elbow Hose Coupling Assembly is key to ensuring its longevity and optimal performance. Inspect the assembly periodically for signs of wear, leaks, or damage. Clean the fittings and seals as part of routine maintenance to prevent buildup that could affect performance. Replace any worn or damaged components promptly to avoid system failures. Following these maintenance practices will help maintain the efficiency and reliability of the truck’s fluid transfer systems.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for truck manufacturers and operators worldwide.

Elbow Hose Coupling Assembly (Part 3099932) in Cummins Engines

The Elbow Hose Coupling Assembly, identified by part number 3099932, is a critical component in the Cummins ISX CM570 and ISX CM870 engines. This part is integral to the engine’s cooling and exhaust systems, ensuring efficient fluid transfer and maintaining optimal engine performance.

In the ISX CM570 engine, the Elbow Hose Coupling Assembly is used to connect various hoses that facilitate the flow of coolant and exhaust gases. Its precise design ensures a secure and leak-free connection, which is vital for the engine’s overall functionality and longevity.

Similarly, in the ISX CM870 engine, the part 3099932 serves the same purpose. Given the higher power output and more demanding operational conditions of the ISX CM870, the reliability and durability of this coupling assembly are even more crucial. It must withstand higher pressures and temperatures, ensuring that the engine operates smoothly and efficiently.

Both engines benefit from the robust construction and precise engineering of the Elbow Hose Coupling Assembly. Its role in maintaining fluid pathways is essential for preventing overheating and ensuring that the engine’s cooling and exhaust systems function correctly. This part is a testament to Cummins’ commitment to quality and performance in their engine designs.

Role of Part 3099932 Elbow Hose Coupling Assembly in Cabin Heater Plumbing

The part 3099932 Elbow Hose Coupling Assembly is an integral component in the cabin heater plumbing system. Its primary function is to facilitate the connection between various hoses that transport heated coolant from the engine to the cabin heater core. This assembly ensures a secure and leak-free junction, which is essential for maintaining the efficiency of the heating system.

In the cabin heater plumbing, the Elbow Hose Coupling Assembly connects the hoses that run from the engine’s coolant system to the heater core located within the vehicle’s dashboard. The assembly allows for a change in direction of the hose routing, accommodating the spatial constraints within the engine compartment and the dashboard.

This part works in conjunction with the thermostat, water pump, and heater control valve to regulate the flow of coolant. When the driver adjusts the temperature settings inside the cabin, the heater control valve modulates the flow of coolant through the heater core. The Elbow Hose Coupling Assembly ensures that this flow is uninterrupted and that the connection points remain intact under varying pressure and temperature conditions.

Additionally, the assembly plays a role in the overall durability and maintenance of the cabin heating system. By providing a robust connection, it reduces the likelihood of hose detachment or leaks, which could otherwise lead to a loss of coolant and a subsequent failure of the heating system.

In summary, the 3099932 Elbow Hose Coupling Assembly is a key element in the cabin heater plumbing, ensuring that the heated coolant is efficiently delivered to the heater core, thereby providing comfortable warmth to the vehicle’s occupants.

Conclusion

The Elbow Hose Coupling Assembly, part number 3099932, is a vital component in the fluid transfer systems of commercial trucks, particularly in Cummins engines and cabin heater plumbing. Its robust design, precise engineering, and reliable performance contribute to the efficient operation and longevity of truck systems. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, ensuring optimal performance and safety in commercial vehicle applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.