This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3105225 Hose Elbow is a component designed for use in commercial truck systems. Manufactured by Cummins Inc., a leader in the automotive industry, this hose elbow serves a specific function within the fluid management systems of trucks. Hose elbows, in general, play a significant role in directing the flow of fluids within a system, ensuring that components receive the necessary fluids for operation and maintenance 1.

Basic Concepts of Hose Elbows

A hose elbow is a fitting used to change the direction of fluid flow within a system. It operates by connecting two sections of hose at an angle, allowing for the redirection of fluid without the need for additional bends or fittings. Hose elbows are typically manufactured from materials such as rubber, metal, or a combination of both, depending on the specific requirements of the system. These materials are chosen for their durability, flexibility, and resistance to the types of fluids they will encounter 2.

Purpose and Function of the 3105225 Hose Elbow

The Cummins 3105225 Hose Elbow is designed to facilitate the routing of fluids within a truck’s system. By changing the direction of fluid flow, it ensures that various components receive the fluids they need for efficient operation. This part plays a role in maintaining the integrity of the fluid system by providing a secure and reliable connection between hoses, which is crucial for the overall performance and longevity of the truck’s system 3.

Key Features

The Cummins 3105225 Hose Elbow features a design that enhances its performance and durability. Constructed from high-quality materials, it is built to withstand the pressures and conditions within a truck’s fluid system. Its design includes elements that ensure a secure fit with hoses, reducing the risk of leaks and ensuring efficient fluid flow. Additionally, the elbow’s construction allows for easy installation and maintenance, making it a practical choice for commercial truck systems.

Benefits of Using the 3105225 Hose Elbow

Incorporating the Cummins 3105225 Hose Elbow into a truck’s system offers several advantages. It improves fluid flow by providing a smooth transition between hoses, reducing the risk of turbulence and pressure drops. The design of the elbow also minimizes the risk of leaks, ensuring that the system remains sealed and efficient. Furthermore, its durability and compatibility with other system components make it a reliable choice for maintaining the performance of commercial trucks.

Installation Considerations

When installing the Cummins 3105225 Hose Elbow, it is important to follow guidelines and best practices to ensure a secure and efficient connection. Proper fitting involves selecting the correct size and type of hose to match the elbow, ensuring that the connection is tight and leak-free. Securing methods, such as clamps or adhesives, should be used as recommended by the manufacturer to maintain the integrity of the connection. Compatibility with existing system components should also be verified to ensure seamless integration.

Troubleshooting and Maintenance

Common issues with hose elbows can include leaks, blockages, or wear and tear. Regular maintenance, such as inspecting for signs of damage or wear, can help prevent these issues. If a problem is detected, such as a leak, it may be necessary to replace the elbow or repair the connection. Following manufacturer guidelines for maintenance and troubleshooting can help ensure the longevity and efficient operation of the Cummins 3105225 Hose Elbow.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines, components, and electronic control systems, as well as related technologies such as aftermarket services, filtration, and emission solutions. Cummins is dedicated to powering a more prosperous world by providing reliable and efficient power solutions across various industries.

Compatibility with Engine Models

The Cummins Hose Elbow part number 3105225 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems.

QSM11 CM570

The QSM11 CM570 engine benefits from the precise fit of the 3105225 Hose Elbow. This part is integral in connecting various hoses that manage the flow of fluids within the engine, ensuring that the system operates efficiently without leaks or blockages.

QSNT14 CM876 N102

Similarly, the QSNT14 CM876 N102 engine incorporates the 3105225 Hose Elbow to facilitate the connection between different components. This part is essential in maintaining the structural integrity of the engine’s piping system, ensuring that all connections are secure and leak-free.

Grouping of Engines

Both the QSM11 CM570 and QSNT14 CM876 N102 engines share a commonality in their requirement for the 3105225 Hose Elbow. This part is designed to fit these specific engine models, providing a reliable connection point for various hoses. The compatibility of this part with these engines ensures that maintenance and repair processes are streamlined, reducing downtime and enhancing overall engine performance.

Role of Part 3105225 Hose Elbow in Engine Systems

The Hose Elbow, identified by part number 3105225, is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases. Its primary function is to provide a smooth transition between two sections of hose or between a hose and a rigid pipe, minimizing turbulence and ensuring a consistent flow.

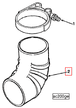

Integration with Plumbing Systems

In engine plumbing systems, the Hose Elbow is often used to connect different sections of the coolant or fuel lines. Its angled design allows for a more streamlined path, reducing the risk of leaks and improving the overall efficiency of fluid transfer. This is particularly important in high-performance engines where maintaining optimal fluid dynamics is key to engine longevity and performance.

Application in Air Cleaner Systems

When integrated into air cleaner systems, the Hose Elbow serves to connect the air intake hose to the air filter housing or the throttle body. This connection is vital for maintaining a sealed and efficient airflow path, ensuring that the engine receives a consistent supply of clean air. The elbow’s design helps to manage the space within the engine compartment, allowing for a more compact and organized layout.

Benefits in Engine Systems

The use of the Hose Elbow in these systems offers several advantages. It enhances the durability of connections by reducing stress points that could lead to wear and tear. Additionally, it contributes to the overall reliability of the engine by ensuring that fluids and gases are directed precisely where needed, without unnecessary bends or restrictions.

Conclusion

In summary, the Hose Elbow (part 3105225) plays a significant role in both plumbing and air cleaner systems within engine configurations, promoting efficient fluid and air flow, and contributing to the engine’s performance and reliability.

-

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.