This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

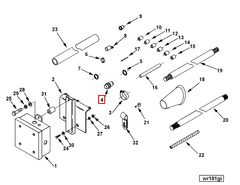

The Hose Nipple 3252954, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces a wide range of parts and systems that enhance the performance and reliability of commercial vehicles. This part is integral to the fluid transfer systems in trucks, ensuring efficient and secure connections between hoses and various components.

Basic Concepts of Hose Nipples

A hose nipple is a short, threaded fitting used to connect hoses to other components within a fluid transfer system. Its primary function is to provide a secure and leak-free connection, facilitating the transfer of fluids such as hydraulic oil, fuel, or coolant. In the context of a truck’s hydraulic or fuel system, hose nipples play a vital role by ensuring that fluids are transferred efficiently and without leakage, which is essential for the system’s overall performance and safety 1.

Purpose of Hose Nipple 3252954

The Hose Nipple 3252954 is specifically designed to connect hoses to various components within a truck’s fluid transfer systems. It ensures a secure and reliable connection, which is essential for maintaining the integrity of the system. By providing a robust interface between hoses and components, this Cummins part helps in the efficient transfer of fluids, contributing to the smooth operation of the truck.

Key Features

The Hose Nipple 3252954 is constructed from high-quality materials, ensuring durability and resistance to corrosion. It features a specific thread type that matches the requirements of the systems it is designed for, allowing for a secure fit. The design of the hose nipple includes features that enhance its performance, such as a tapered thread that provides a tight seal and reduces the risk of leaks. Additionally, the material composition ensures that it can withstand the pressures and temperatures encountered in commercial truck applications 2.

Benefits

The Hose Nipple 3252954 offers several advantages. Its design enhances fluid transfer efficiency by providing a secure and leak-free connection. The ease of installation is another significant benefit, as the threaded design allows for quick and straightforward attachment to compatible components. Furthermore, its reliability in harsh operating conditions ensures that it maintains performance over time, reducing the need for frequent replacements and maintenance.

Installation and Usage

Proper installation of the Hose Nipple 3252954 is crucial for ensuring a secure connection. It is recommended to follow torque specifications provided by the manufacturer to achieve the correct tightness without over-tightening, which could damage the threads. Best practices include inspecting the threads for damage before installation and ensuring that the connection is free from debris. Using a torque wrench can help achieve the precise torque required for a secure fit.

Troubleshooting and Maintenance

Common issues with hose nipples include leaks and corrosion. To troubleshoot these problems, inspect the connections regularly for signs of wear or damage. If a leak is detected, ensure that the nipple is properly tightened and that there is no damage to the threads or the hose. Corrosion can be addressed by cleaning the affected areas and applying a compatible corrosion-resistant coating. Regular maintenance, such as periodic inspection and cleaning, can help prolong the lifespan of the Hose Nipple 3252954.

Safety Considerations

When working with hose nipples, it is important to observe several safety precautions. Proper handling involves using the correct tools and following manufacturer guidelines to avoid damage to the component or injury to the technician. Inspection procedures should be conducted regularly to identify any signs of wear, damage, or corrosion. In the event of a failure, having an emergency response plan in place, including the availability of replacement parts and knowledge of safe shutdown procedures, is crucial to minimize risks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance parts. The company’s extensive product range and commitment to innovation have made it a trusted name among fleet operators and maintenance professionals.

Cummins Hose Nipple Part 3252954 in Engine Applications

The Cummins Hose Nipple part number 3252954 is a critical component in various engine systems, ensuring the integrity of fluid pathways and maintaining operational efficiency. This part is designed to connect hoses securely to the engine, preventing leaks and maintaining pressure within the system.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Hose Nipple part 3252954 plays a vital role in the cooling and fuel systems. It is typically used to connect coolant hoses to the engine block, ensuring that the coolant flows efficiently through the engine to maintain optimal operating temperatures. Additionally, this part may also be used in the fuel system to connect fuel lines, ensuring that the engine receives a consistent fuel supply.

Group Applications

The Hose Nipple part 3252954 is not limited to the N14 MECHANICAL engines alone. It is also utilized in other Cummins engine groups where similar fluid management is required. This part’s versatility makes it a common component across various engine models, ensuring compatibility and ease of maintenance across different engine types.

Role of Part 3252954 Hose Nipple in Engine Systems

The part 3252954 Hose Nipple is an essential component in various engine systems, facilitating the secure connection between hoses and other components. Its application spans across multiple subsystems, ensuring efficient fluid transfer and maintaining system integrity.

Integration with Accessories

In engine systems, the Hose Nipple is often utilized to connect accessories that require fluid or gas transfer. This includes components such as fuel injectors, where precise fuel delivery is necessary, and cooling system components like radiators and thermostats. The secure fitting provided by the Hose Nipple ensures that these accessories operate efficiently without leaks, which is vital for the overall performance and longevity of the engine.

Wiring and Electrical Systems

While the Hose Nipple is primarily a fluid transfer component, its role extends into the electrical domain through its integration with wiring harnesses. In modern engines, sensors and control units often require coolant or other fluids for temperature regulation. The Hose Nipple ensures a reliable connection between these sensors and the fluid lines, preventing electrical issues that could arise from fluid leaks or inconsistent sensor readings.

Engine Wiring and Harnesses

The Hose Nipple also plays a part in the engine’s wiring and harness systems. In complex engine setups, various sensors and actuators are positioned throughout the engine bay. These components may need to be cooled or have fluids supplied to them for optimal operation. The Hose Nipple provides a stable and leak-proof connection, which is particularly important in high-vibration environments typical of engine compartments. This stability ensures that the wiring and harnesses remain intact and function correctly, contributing to the engine’s reliable operation.

Electrically-Driven Blower Motors (EB Motors)

In systems utilizing electrically-driven blower motors (EB Motors), the Hose Nipple is used to connect air intake and exhaust hoses. These motors often require precise air flow for cooling and operation. The Hose Nipple ensures that the air pathways are secure, preventing any disruptions in air flow that could affect the motor’s performance and efficiency.

Conclusion

Overall, the part 3252954 Hose Nipple is a versatile component that enhances the functionality and reliability of various engine systems. Its role in connecting accessories, ensuring secure fluid transfer in wiring and electrical systems, maintaining the integrity of engine wiring and harnesses, and supporting the operation of EB Motors underscores its importance in modern engine design.

References

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.