This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

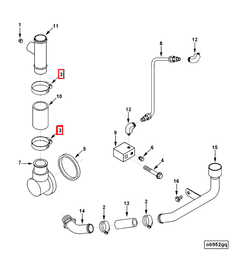

The Hose Clamp Assembly 3254314, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is part of this extensive product line, playing a role in ensuring the secure connection of hoses within a truck’s fluid systems.

Basic Concepts of Hose Clamp Assemblies

Hose clamp assemblies are devices used to secure hoses in fluid systems, ensuring a tight and leak-free connection. They operate by applying pressure around the hose and the fitting it connects to, creating a seal that prevents fluid leakage. These assemblies are vital in various applications, from automotive to industrial systems, where fluid transfer is necessary 1.

Purpose of the 3254314 Hose Clamp Assembly

This part is specifically designed to secure hoses within the fluid systems of commercial trucks. Its application ensures that hoses remain firmly attached to their fittings, facilitating the efficient transfer of fluids such as coolant, fuel, or hydraulic fluid. This secure connection is vital for the operation of the truck, as it helps maintain system integrity and performance.

Key Features

The 3254314 features a design that includes high-quality materials for durability and performance. It is constructed with a band made from corrosion-resistant materials, ensuring longevity even in harsh operating environments. The design incorporates elements that enhance its ability to grip hoses securely, such as serrated edges that dig into the hose for a tighter hold. Additionally, the assembly may include features that facilitate easy installation and adjustment, such as a screw mechanism for precise clamping force application.

Benefits

The advantages of using the 3254314 include improved reliability in hose connections, which contributes to the overall efficiency of the truck’s fluid systems. Its design allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, the clamp’s construction and materials contribute to low maintenance requirements, offering long-term cost savings and reliability.

Installation Process

Installing the 3254314 involves several steps to ensure a secure and effective connection. Begin by selecting the appropriate clamp size for the hose diameter. Position the clamp around the hose and fitting, ensuring it is aligned correctly. Use the screw mechanism to tighten the clamp gradually, applying even pressure around the hose. It is important to avoid over-tightening, which can damage the hose or fitting. Verify the connection by checking for leaks after the system is pressurized.

Troubleshooting and Maintenance

Common issues with hose clamp assemblies include leaks, which can often be traced back to improper installation or wear and tear on the clamp or hose. Regular inspection of clamps for signs of corrosion, damage, or loosening can help identify potential problems before they lead to system failure. Maintenance practices should include checking the tightness of clamps periodically and replacing any that show signs of wear or damage. When replacing a clamp, ensure the new one is compatible with the hose and fitting to maintain system integrity.

Compatibility and Usage

The 3254314 is typically used in commercial trucks for securing hoses in various fluid systems. It is compatible with a range of hose sizes and materials, making it versatile for different applications within the truck. Common uses include connections in the cooling system, fuel lines, and hydraulic systems, where secure and leak-free connections are critical for system performance and safety.

Safety Considerations

When working with hose clamp assemblies, it is important to observe safety guidelines to prevent accidents or system failures. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against sharp edges or fluid spills. Ensure that the system is depressurized before attempting any maintenance or installation work to avoid injury from pressurized fluid. Follow manufacturer guidelines for installation and maintenance to ensure the clamp operates safely and effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the commercial vehicle industry. The company’s extensive product range and commitment to customer satisfaction underscore the quality and reliability of components like the 3254314 Hose Clamp Assembly 2.

Compatibility with Cummins Engines

The 3254314 is a versatile component designed to fit a variety of engine models. This part is essential for securing hoses and ensuring leak-free connections in various engine systems. Below is a detailed overview of its compatibility with the listed engines:

- 6C8.3, C8.3 G: The 3254314 is compatible with these engines, providing a reliable seal for the hoses in the engine’s cooling and fuel systems.

- ISF3.8 CM2220 F103, ISG11 CM2880 G108, ISG12 CM2880 G107: These engines benefit from the 3254314, ensuring that all critical hoses are securely fastened, which is crucial for maintaining engine performance and preventing leaks.

- QSK19 CM850 MCRS, QSK60 CM500, QSK60G: The 3254314 part is designed to fit these heavy-duty engines, providing the necessary durability and strength to handle the high-pressure environments within these systems.

- V903: This engine model also utilizes the 3254314 Hose Clamp Assembly, ensuring that hoses are properly secured and that the engine operates efficiently.

- X11 CM2670 X126B, X12 CM2670 X121B, X13 CM2670 X122B: These engines are part of the Cummins X Series, and the 3254314 is engineered to fit these models, providing a secure and reliable connection for all necessary hoses.

Grouping of Compatible Engines

The 3254314 is designed to be a universal fit for a range of engine models, making it a valuable component for maintenance and repair. By grouping the engines based on their compatibility, it becomes clear that this part is suitable for both light-duty and heavy-duty applications, ensuring that it can be used across various engine types and sizes.

Role of Part 3254314 Hose Clamp Assembly in Engine Systems

The Hose Clamp Assembly, identified by part number 3254314, is an essential component in securing and maintaining the integrity of various hose connections within engine systems. Its application spans across multiple subsystems, ensuring efficient operation and preventing leaks.

Aftercooler and Cooler Systems

In aftercooler and cooler systems, the Hose Clamp Assembly is utilized to secure hoses that transport coolant or air to and from the aftercooler and cooler units. This ensures that the cooling process is efficient, maintaining optimal engine temperatures and performance.

Crankcase Breather and Plumbing

For the crankcase breather system, the Hose Clamp Assembly plays a role in securing hoses that vent crankcase gases. Proper sealing is necessary to prevent oil contamination and ensure that the breather system functions correctly, contributing to engine longevity.

Engine Oil and Lubricating Oil Systems

Within the engine oil and lubricating oil systems, the Hose Clamp Assembly is employed to fasten hoses that circulate oil to various engine components. This includes connections to the oil filter, oil cooler, and other critical parts, ensuring a consistent supply of lubrication and cooling.

Housing and Thermostat

In housing units, particularly those enclosing the thermostat, the Hose Clamp Assembly is used to secure hoses that connect to the thermostat housing. This is vital for regulating coolant flow based on engine temperature, contributing to engine efficiency and protection against overheating.

Oil Cooler Mounting and Plumbing

For oil cooler mounting and associated plumbing, the Hose Clamp Assembly is crucial in securing hoses that transport oil to and from the oil cooler. This setup is essential for dissipating heat from the oil, ensuring it remains within the optimal temperature range for engine operation.

Aftercooler Water and Exhaust Recirculation Air Plumbing

In aftercooler water and exhaust recirculation air plumbing, the Hose Clamp Assembly ensures that hoses are tightly secured, facilitating the efficient transfer of water or air as required by these systems. This contributes to the overall efficiency and environmental compliance of the engine.

Water Bypass Tube and Rubber T-Piece Upfit Kit

Lastly, in applications involving a water bypass tube or a rubber T-piece upfit kit, the Hose Clamp Assembly is used to secure connections that may require modification or additional fittings. This flexibility allows for customized engine configurations, enhancing performance or accommodating specific operational requirements.

Conclusion

Overall, the Hose Clamp Assembly (part 3254314) is a versatile and indispensable component in engine systems, facilitating secure and leak-free connections across a wide range of applications. Its role in maintaining the integrity of hose connections is critical for the efficient operation of commercial trucks and various engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.