This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3254435 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces this coupling to enhance the efficiency and reliability of fluid transfer systems in trucks. This part is integral to maintaining the smooth operation of various truck systems by ensuring secure and efficient fluid connections.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to join two hoses at an angle, typically 90 degrees, allowing for fluid transfer in systems where space constraints or design requirements necessitate a change in direction. These couplings are vital in fluid systems as they facilitate the movement of liquids or gases between components while accommodating the spatial limitations within the truck’s chassis. They operate by providing a sealed connection that can withstand the pressures and temperatures of the fluid being transported 1.

Purpose of the 3254435 Elbow Hose Coupling

The 3254435 is specifically designed to play a role in the fluid transfer systems of trucks. It is applied in various applications such as coolant, fuel, or hydraulic lines. By providing a reliable connection point, it ensures that fluids are transferred efficiently throughout the truck’s systems, contributing to the overall performance and longevity of the vehicle 2.

Key Features

This Cummins part is constructed with materials that offer durability and resistance to the pressures and temperatures encountered in truck fluid systems. Its design includes specific connection types that ensure a secure fit with hoses and other system components. Unique attributes of this coupling may include enhanced sealing mechanisms or corrosion-resistant materials, which contribute to its performance and durability in demanding environments.

Benefits

Utilizing the 3254435 offers several advantages. It improves fluid flow by providing a smooth transition between hoses, reduces the risk of leakage through its secure connection design, and enhances system reliability by ensuring consistent fluid transfer. These benefits contribute to the efficient operation of the truck and can lead to reduced maintenance needs and increased uptime.

Installation Considerations

When installing the 3254435, it is important to follow guidelines and best practices to ensure proper function. This includes adhering to torque specifications for tightening connections, ensuring correct alignment with other system components, and verifying compatibility with the hoses and systems it will be used with. Proper installation is key to maximizing the performance and longevity of the coupling.

Troubleshooting and Maintenance

Common issues with the 3254435 may include leaks, connection failures, or wear and tear from use. Diagnostic methods for identifying problems can involve visual inspections, pressure tests, or analyzing system performance data. Maintenance practices to ensure the longevity and optimal performance of the coupling include regular inspections, cleaning, and replacing worn components as needed.

Compatibility and Applications

The 3254435 is designed for use in various truck models and systems, demonstrating its versatility and widespread application. It is compatible with a range of hose sizes and types, making it a suitable choice for many fluid transfer applications within the commercial truck industry.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation for quality and reliability. Founded with a commitment to innovation and excellence, Cummins has built a diverse product portfolio that includes engines, filtration systems, and components like the 3254435. The company’s focus on customer satisfaction and technological advancement underscores the quality and dependability of its products.

Engine Compatibility with Elbow Hose Coupling Part 3254435

The 3254435, manufactured by Cummins, is a component in the engine systems of the N14 CELECT PLUS and N14 MECHANICAL engines. This part is designed to facilitate the connection between hoses and engine components, ensuring a secure and leak-proof seal.

In the N14 CELECT PLUS engine, the 3254435 is integral to the engine’s fuel and coolant systems. It ensures that the hoses remain firmly attached to the engine, preventing any potential leaks that could compromise engine performance or lead to system failures. The precision engineering of this coupling ensures that it can withstand the high pressures and temperatures typical of modern diesel engines.

Similarly, in the N14 MECHANICAL engine, the 3254435 plays a role in maintaining the integrity of the hose connections. This engine, known for its robust and reliable performance, relies on the secure attachment of hoses to various engine components. The coupling’s design allows for easy installation and removal, facilitating maintenance and repairs.

Both engines benefit from the use of this part, as it contributes to the overall efficiency and reliability of the engine systems. The compatibility of the 3254435 with these engines underscores Cummins’ commitment to providing high-quality components that meet the demanding requirements of modern diesel engines.

Role of Part 3254435 Elbow Hose Coupling in Engine Systems

The 3254435 is integral to the efficient operation of various engine systems by facilitating secure and reliable connections between components. Its application spans across several key areas:

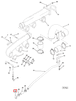

Compressor Air Inlet and Air Compressor Inlet

In the arrangement of the compressor air inlet and air compressor inlet, the Elbow Hose Coupling ensures a snug fit, minimizing air leaks. This is essential for maintaining the desired pressure levels and ensuring the compressor operates within its optimal range.

EBM: Plumbing and Turbocharger Systems

When integrated into the EBM (Engine Bay Management) plumbing and turbocharger systems, the Elbow Hose Coupling plays a role in directing the flow of fluids and gases. It connects the turbocharger to the manifold exhaust, ensuring that exhaust gases are efficiently routed to drive the turbine.

Turbocharger Mounting and Oil Drain Plumbing

In turbocharger mounting scenarios, the Elbow Hose Coupling is used to connect the turbocharger to its oil drain plumbing. This connection is vital for lubricating the turbocharger bearings, which are subject to high speeds and temperatures.

Turbocharger Plumbing—Lower

For the lower section of the turbocharger plumbing, the Elbow Hose Coupling provides a flexible yet robust connection. This is particularly important in managing the high-pressure and high-temperature environments typical in turbocharger applications.

Overall, the Elbow Hose Coupling is a versatile component that enhances the reliability and performance of engine systems by ensuring secure and efficient connections between various critical components.

Conclusion

The 3254435 Elbow Hose Coupling by Cummins is a critical component in the fluid transfer systems of commercial trucks, offering durability, reliability, and efficiency. Its application across various engine systems underscores its importance in maintaining the performance and longevity of truck operations. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.