This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

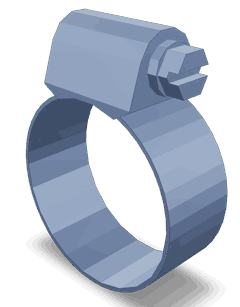

The Hose Clamp 3255112, manufactured by Cummins, is designed to meet the rigorous demands of commercial truck operations, ensuring secure connections in various systems where hoses are utilized.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight seal that prevents leaks and maintains system integrity. They are commonly constructed from materials such as stainless steel, aluminum, or plastic, chosen for their durability, resistance to corrosion, and ability to withstand high temperatures and pressures 1.

Purpose of Hose Clamp 3255112 in Truck Operations

This Cummins part plays a role in the operation of commercial trucks by securing hoses in critical systems such as the fuel, coolant, and hydraulic systems. It is designed to operate in demanding environments, providing a reliable seal that can withstand vibrations, temperature fluctuations, and exposure to various chemicals 2.

Key Features of Hose Clamp 3255112

The design of this part incorporates several elements that contribute to its effectiveness and durability. The band material is selected for its strength and resistance to environmental factors. The screw design allows for easy adjustment and secure clamping, while the adjustment mechanism ensures a consistent and tight seal around the hose 3.

Benefits of Using Hose Clamp 3255112

Utilizing this part offers several advantages. Its design facilitates ease of installation, making it a practical choice for maintenance and repair tasks. The clamp demonstrates reliability under stress, maintaining a secure seal even in dynamic operating conditions. Additionally, its resistance to environmental factors ensures longevity and consistent performance.

Installation and Adjustment Procedures

To install the Hose Clamp 3255112, position the clamp around the hose and fitting, ensuring it is aligned correctly. Use the screw to tighten the clamp gradually, adjusting until the desired tension is achieved. This process should be performed carefully to avoid over-tightening, which could damage the hose.

Troubleshooting Common Issues

Frequent problems with hose clamps may include leaks, difficulty in adjustment, or corrosion. These issues can often be traced to improper installation, environmental exposure, or material degradation. Solutions may involve re-tightening the clamp, replacing damaged components, or selecting clamps made from more resistant materials.

Maintenance Tips

Regular maintenance of hose clamps involves inspecting for signs of wear, corrosion, or leaks. Ensuring the clamp is properly tightened and replacing any damaged components can prevent issues and prolong the lifespan of the clamping system. Additionally, protecting the clamps from harsh environmental conditions can enhance their durability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry, offering a wide range of products designed to meet the needs of various applications.

Compatibility of Hose Clamp 3255112 with Cummins Engines

This Cummins part is designed to fit a range of Cummins engines. Below is a detailed look at the compatibility of this part with specific Cummins engine models:

ISM Series Engines

- ISM CM570: Compatible with the ISM CM570 engine, providing a secure fit for the necessary hose connections.

- ISM CM570/870: Utilizes the Hose Clamp 3255112, ensuring that hoses are properly secured in both engine variants.

- ISM CM876: Benefits from the use of the Hose Clamp 3255112, maintaining the integrity of hose connections.

- ISM11 CM876 SN: Incorporates the Hose Clamp 3255112, ensuring that hoses are tightly clamped and secure.

M11 Series Engines

- M11 CELECT PLUS: Compatible with the M11 CELECT PLUS engine, providing a reliable seal for hose connections in this model.

N14 Series Engines

- N14 CELECT PLUS: Fits the N14 CELECT PLUS engine, ensuring that hoses are properly secured and leak-free.

QSM11 Series Engines

- QSM11 CM570: Suitable for the QSM11 CM570 engine, offering a dependable solution for hose clamping needs.

Each of these engines relies on the Hose Clamp 3255112 to maintain the integrity of their hose connections, ensuring that the engines operate efficiently and safely.

Role of Hose Clamp 3255112 in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine systems. In the arrangement of engine components, this hose clamp ensures that hoses are securely fastened, preventing leaks and ensuring a consistent flow of fluids.

For the oil fill system, the hose clamp plays a significant role in securing the hoses that connect the oil fill port to the cylinder block. This secure connection is essential for maintaining oil pressure and ensuring that the engine receives the necessary lubrication for smooth operation.

In the context of the cover components, such as those over the cylinder block or hand hole, the hose clamp helps in sealing any fluid passages that run through or around these covers. This sealing is vital for preventing oil or coolant leaks, which could lead to engine damage or inefficient performance.

Additionally, for the gauge and oil level monitoring systems, the hose clamp ensures that the hoses connected to these gauges are firmly in place. This secure connection allows for accurate readings of oil levels and pressure, enabling engineers and mechanics to monitor the engine’s health and performance effectively.

Overall, the Hose Clamp 3255112 is a fundamental component in ensuring the reliable operation of various engine systems by maintaining secure and leak-free connections across different fluid pathways.

Conclusion

The Hose Clamp 3255112 by Cummins is a critical component in the maintenance and operation of commercial truck engines. Its design and features ensure secure and reliable connections in various engine systems, contributing to the overall efficiency and safety of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Reif, Konrad, ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Reif, Konrad, ed. Diesel Engine Management Systems and Components. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.