This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Elbow Hose Connector 3282322, manufactured by Cummins, is a component designed for use in commercial truck systems. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the performance and reliability of commercial vehicles. This Cummins part is significant in these systems due to its role in facilitating efficient fluid transfer and maintaining the integrity of various fluid pathways within the truck.

Function and Operation

The Elbow Hose Connector 3282322 operates by directing the flow of fluids within a truck’s system. It is positioned at angles to allow for changes in direction of fluid flow, which is crucial for navigating the complex layout of hoses and pipes in a commercial truck. This connector ensures that fluid systems, such as coolant, fuel, and hydraulic lines, function smoothly by providing a secure and leak-resistant connection point 1.

Purpose of the Elbow Hose Connector

The Elbow Hose Connector serves a specific role in the operation of a truck by enabling the efficient transfer of fluids through angled connections. It is applied in various fluid systems, including coolant circuits to manage engine temperature, fuel lines to ensure proper delivery to the engine, and hydraulic systems that operate various truck functions. Its design allows for flexibility in routing hoses, which is particularly beneficial in the confined spaces typical of truck engine compartments 2.

Key Features

The design and construction of the Elbow Hose Connector 3282322 include several features that enhance its performance and durability. It is typically made from high-quality materials resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The connector features secure clamping mechanisms to prevent leaks and maintain a tight seal. Additionally, its angled design allows for versatile installation in various configurations, accommodating the specific needs of different truck models and fluid systems 3.

Benefits

Using the Elbow Hose Connector 3282322 offers several advantages. It improves fluid dynamics by ensuring smooth and uninterrupted flow through angled connections. The secure design reduces the risk of leaks, which can lead to system failures or inefficiencies. Furthermore, the robust construction enhances the overall reliability of the fluid systems in which it is installed, contributing to the truck’s performance and longevity.

Installation Considerations

When installing the Elbow Hose Connector, it is important to follow guidelines and best practices to ensure optimal performance. This includes adhering to specified torque values for clamping mechanisms to achieve a secure seal without over-tightening, which could damage the connector or hoses. Proper alignment of the connector with the hoses and other system components is also crucial to maintain the intended fluid flow path and prevent stress on the connections.

Troubleshooting Common Issues

Typical problems associated with Elbow Hose Connectors may include leaks or blockages. To address these issues, it is recommended to first inspect the connector and hoses for signs of wear, damage, or misalignment. Ensuring that the clamping mechanisms are properly tightened and that the connector is correctly aligned can often resolve these problems. In cases where damage is detected, replacement of the affected components may be necessary to restore system integrity.

Maintenance Tips

To ensure the long-term performance of the Elbow Hose Connector, regular maintenance is advised. This includes routine inspections for signs of wear, corrosion, or leaks. Cleaning the connector and surrounding areas can prevent buildup that might interfere with its operation. Additionally, monitoring the condition of the hoses and clamps for signs of degradation and replacing them as needed will help maintain the efficiency and reliability of the fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s extensive product range is designed to meet the diverse needs of commercial vehicle operators, enhancing performance, efficiency, and uptime.

Engine Compatibility with Elbow Hose Connector Part 3282322

The Elbow Hose Connector part 3282322, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring proper hose connections.

6B5.9 Engine

The 6B5.9 engine is one of the models that benefit from the precise fit and robust construction of the 3282322 Elbow Hose Connector. This part ensures that the hose connections are secure and leak-free, which is vital for the engine’s performance and longevity.

6C8.3 Engine

Similarly, the 6C8.3 engine is another model that is compatible with the 3282322 Elbow Hose Connector. This part is engineered to meet the specific requirements of the 6C8.3 engine, providing a reliable connection that can withstand the operational stresses of the engine.

Grouping of Engines

Both the 6B5.9 and 6C8.3 engines share common design principles and operational requirements, making them suitable candidates for the 3282322 Elbow Hose Connector. The compatibility of this part with these engines underscores its versatility and importance in maintaining the functionality of the engine’s systems.

Role of Part 3282322 Elbow Hose Connector in Engine Systems

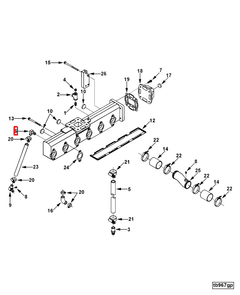

The Elbow Hose Connector (Part 3282322) is integral to the efficient operation of several engine systems, particularly in the context of aftercooler plumbing and turbocharger arrangements.

In the aftercooler plumbing system, the Elbow Hose Connector facilitates the redirection of coolant flow. It connects the water inlet to the aftercooler, ensuring that the coolant effectively absorbs heat from the compressed air. This connection is vital for maintaining optimal temperatures, which in turn enhances the efficiency and performance of the aftercooler.

Within the turbocharger arrangement, the Elbow Hose Connector plays a significant role in managing the flow of aftercooler water. It ensures a smooth transition between different sections of the plumbing, reducing the risk of leaks and maintaining consistent pressure throughout the system. This is particularly important in high-performance engines where even minor inefficiencies can lead to significant performance drops.

Additionally, the Elbow Hose Connector is often used in the turbocharger mounting system. Here, it helps in securing various hoses and pipes, ensuring that they remain in place under the high pressures and temperatures associated with turbocharger operation. This not only improves the reliability of the system but also contributes to the overall durability of the engine components.

Conclusion

In summary, the Elbow Hose Connector (Part 3282322) is a versatile component that enhances the functionality and reliability of both the aftercooler and turbocharger systems. Its role in facilitating smooth, secure connections is essential for the efficient operation of these complex engine components.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩ -

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.