This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

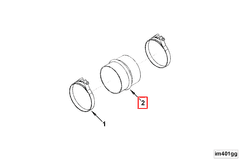

The Cummins 3331516 Hump Hose is a specialized component designed for use in commercial trucks. It plays a role in the vehicle’s fluid transfer system, ensuring efficient operation and system integrity. This Cummins part is engineered to withstand the demanding conditions encountered in heavy-duty applications, providing reliable performance and durability 1.

Purpose and Function

The primary purpose of the 3331516 Hump Hose is to facilitate the transfer of fluids within the truck’s system. It is specifically designed to manage the flow of coolant, oil, or other fluids, ensuring that they reach their intended destinations without leakage or contamination. By maintaining consistent fluid levels and pressure, the hose contributes to the overall efficiency and reliability of the truck’s systems 2.

Key Features

The 3331516 Hump Hose boasts several key features that enhance its performance and durability. Its design incorporates reinforced layers to withstand high pressure and temperature fluctuations. The hose is constructed from high-quality materials, including synthetic rubber and textile reinforcements, which provide flexibility and strength. Additionally, the hose features smooth inner and outer surfaces to reduce friction and wear, ensuring long-lasting operation 3.

Benefits

The use of the 3331516 Hump Hose offers several benefits to commercial truck operators. It contributes to improved system efficiency by ensuring consistent fluid transfer and reducing the risk of leaks. The hose’s durable construction minimizes maintenance needs, allowing for extended periods between replacements. Furthermore, its reliable performance enhances the overall dependability of the truck’s systems, leading to increased uptime and reduced downtime 4.

Installation and Compatibility

Proper installation of the 3331516 Hump Hose is crucial to ensure optimal performance and system integrity. It is important to follow manufacturer guidelines and recommendations during installation to avoid potential issues. The hose is designed to be compatible with a wide range of commercial truck models, but it is essential to verify compatibility with the specific make and model of the truck to ensure a proper fit and function 5.

Maintenance and Troubleshooting

Regular maintenance of the 3331516 Hump Hose is necessary to ensure its continued reliable performance. This includes periodic inspections for signs of wear, cracking, or leaks. Common issues to watch for include fluid leaks, hose deformation, and connection failures. Troubleshooting steps may involve checking for proper installation, inspecting fittings and connections, and addressing any detected issues promptly to prevent further damage 6.

Performance in Various Conditions

The 3331516 Hump Hose is engineered to perform effectively under a variety of operating conditions. It is designed to withstand extreme temperatures, high pressure, and varying load conditions commonly encountered in commercial truck applications. Its robust construction and materials ensure reliable performance even in challenging environments, contributing to the overall durability and efficiency of the truck’s systems 7.

Comparison with Other Hoses

When compared to other types of hoses used in commercial trucks, the 3331516 Hump Hose offers several advantages. Its reinforced design and high-quality materials provide superior durability and resistance to wear and tear. In specific scenarios where high pressure or temperature fluctuations are present, the 3331516 Hump Hose may be preferred due to its enhanced performance characteristics 8.

Customer Reviews and Feedback

Customer reviews and feedback on the 3331516 Hump Hose provide valuable insights into its real-world performance. Many users praise its durability, reliability, and ease of installation. Common praises include its ability to withstand harsh operating conditions and its contribution to improved system efficiency. Some criticisms may relate to specific installation challenges or compatibility issues, highlighting the importance of following manufacturer guidelines 9.

Manufacturer Information

Cummins, the manufacturer of the 3331516 Hump Hose, is a reputable company with a long-standing history in the automotive and heavy-duty truck industry. Known for its commitment to quality and innovation, Cummins has established itself as a trusted provider of reliable components for commercial vehicles. The company’s dedication to excellence is reflected in the design and performance of the 3331516 Hump Hose, ensuring that it meets the demanding requirements of heavy-duty applications 10.

Role of Part 3331516 Hump Hose in Engine Systems

The 3331516 Hump Hose is an integral component in various engine systems, facilitating efficient operation and performance. Its applications span across multiple subsystems, each playing a distinct role in the overall functionality of the engine.

Accessories

In accessory systems, the Hump Hose is often utilized to route fluids or gases to and from auxiliary components. This ensures that accessories such as turbochargers, intercoolers, and other performance-enhancing devices receive the necessary media for optimal operation.

Air Intake

Within the air intake system, the Hump Hose connects the air filter to the throttle body or intake manifold. This connection is vital for maintaining a sealed pathway, ensuring that unfiltered air does not enter the engine, which could lead to decreased performance and increased wear.

Aftercooler

In aftercooler systems, the Hump Hose is employed to direct cooled air from the aftercooler to the intake manifold. This process enhances the density of the air entering the combustion chamber, resulting in improved engine efficiency and power output.

Charge Air Cooler Tubes Kit

When integrated into a charge air cooler tubes kit, the Hump Hose plays a role in connecting the charge air cooler to the intake tract. This setup helps in managing the temperature of the air charge, which is essential for maintaining consistent engine performance under varying conditions.

Connection

As a connection component, the Hump Hose is used to link various parts of the engine system, ensuring a secure and leak-free pathway for fluids and gases. This is particularly important in high-pressure systems where any leak could result in significant performance issues.

Radiator Plumbing

In radiator plumbing, the Hump Hose is utilized to connect the radiator to the engine block or other cooling system components. This ensures efficient circulation of coolant, which is essential for maintaining optimal engine operating temperatures.

Exchanger

Within heat exchanger systems, the Hump Hose facilitates the transfer of heat between fluids. This is crucial for systems that require precise temperature control, such as intercoolers and charge air coolers.

Heat Exchanger and Mounting

For heat exchanger and mounting applications, the Hump Hose provides a flexible connection that can accommodate the movement and vibration inherent in engine operation. This flexibility helps in reducing stress on the connections, prolonging the lifespan of the system.

Hose

As a general hose component, the Hump Hose is used in various applications where a durable, flexible connection is required. Its versatility makes it suitable for a wide range of engine systems, from cooling to intake and exhaust.

Radiator

In radiator systems, the Hump Hose connects the radiator to the engine and other cooling components. This ensures that coolant is efficiently circulated through the system, helping to dissipate heat and maintain engine temperature within safe limits.

Radiator and Plumbing

Finally, in comprehensive radiator and plumbing systems, the Hump Hose is a key component in ensuring that all connections are secure and leak-free. This is essential for maintaining the integrity of the cooling system and ensuring that the engine operates within its designed parameters.

Conclusion

The Cummins 3331516 Hump Hose is a critical component in the engine systems of several models, contributing to the overall functionality and reliability of the engines. Its applications span across multiple subsystems, each playing a distinct role in the efficient operation of the engine. Proper installation, regular maintenance, and understanding its role in various engine systems are essential for maximizing the performance and longevity of this component.

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 6314881, Engine: Z14 CM2670 Z109C.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.