This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3349150 Flexible Hose is a component designed for use in commercial truck systems. It serves as a conduit for various fluids within the truck’s operational framework, ensuring efficient and reliable performance. This part is integral to maintaining the functionality of several systems within the vehicle.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to transport fluids such as coolant, fuel, and hydraulic fluid. They are designed to accommodate movement and vibration, which are common in vehicle operations. Flexible hoses provide a durable yet adaptable connection between components, allowing for the transfer of fluids without the risk of breakage or leakage that rigid pipes might present 1.

Purpose of the 3349150 Flexible Hose

The Cummins 3349150 Flexible Hose plays a specific role in the operation of a truck by connecting various systems and transporting essential fluids. It is typically used in applications where flexibility and durability are required to withstand the dynamic environment of a commercial truck. This hose may be part of the fuel system, coolant system, or other fluid transport mechanisms within the truck.

Key Features

The Cummins 3349150 Flexible Hose is characterized by several key features that enhance its performance. These include a material composition designed for durability and resistance to the fluids it transports. The hose exhibits flexibility, allowing it to bend and move with the truck’s components without compromising integrity. Additionally, design elements such as reinforced layers and specialized fittings contribute to its robust performance in demanding conditions.

Benefits

Using the Cummins 3349150 Flexible Hose provides several advantages. It contributes to improved system reliability by reducing the risk of leaks and breakages that can occur with rigid hoses. The hose’s flexibility and durability ensure a longer service life, minimizing the need for frequent replacements. Moreover, its design helps in accommodating the natural movements and vibrations of the truck, leading to a more stable and efficient fluid transport system.

Installation Considerations

When installing the Cummins 3349150 Flexible Hose, it is important to follow guidelines and best practices to ensure proper integration within the truck’s system. This includes using the correct fitting techniques to secure the hose connections, ensuring that the hose is aligned correctly to prevent kinks or stress points, and verifying that all connections are tight and secure to prevent fluid leaks.

Troubleshooting Common Issues

Common problems associated with flexible hoses include leaks, kinks, or degradation over time. To address these issues, regular inspections should be conducted to identify any signs of wear or damage. If a leak is detected, the source should be located and the hose may need to be repaired or replaced. Kinks can often be resolved by rerouting the hose or adjusting its position to remove the constriction. Degradation may require replacement of the hose to maintain system integrity.

Maintenance Tips

Maintaining the Cummins 3349150 Flexible Hose involves regular inspection routines to check for signs of wear, such as cracks, bulges, or soft spots. It is also important to look for any evidence of fluid leaks around the hose connections. If any damage is found, or if the hose shows signs of significant wear, it may be necessary to consider replacement to ensure continued reliable operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the commercial truck industry. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins is known for its commitment to quality and innovation, providing reliable solutions that meet the demanding requirements of commercial trucking operations 2.

Compatibility with K38 and K50 Engines

The Cummins Flexible Hose part number 3349150 is designed to seamlessly integrate with the K38 and K50 engine families. This hose is engineered to provide a reliable and durable connection between various fluid systems within these engines, ensuring optimal performance and longevity.

K38 Engine Family

The K38 engine series is known for its robust design and efficiency. The part 3349150 is specifically tailored to fit the intricate layout of the K38 engines, providing a flexible yet strong connection that can withstand the rigors of continuous operation. This hose is critical in maintaining the fluid dynamics within the engine, ensuring that all components receive the necessary fluids for smooth operation.

K50 Engine Family

Similarly, the K50 engine family benefits from the use of the Cummins Flexible Hose part number 3349150. This engine series is designed for heavy-duty applications, and the hose is engineered to meet these demanding requirements. The flexibility of the hose allows it to adapt to the engine’s movements and vibrations, reducing the risk of leaks and ensuring a secure connection.

Common Features

Both the K38 and K50 engines share certain design philosophies that make the part 3349150 a perfect fit. These engines are built to handle high-stress environments, and the hose is made from high-quality materials that can endure these conditions. The precise engineering of the hose ensures that it fits snugly in the designated areas, providing a leak-proof seal that is essential for the engine’s performance.

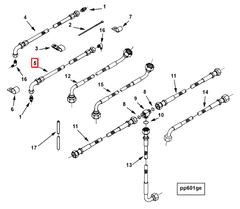

Role of Part 3349150 Flexible Hose in Engine Systems

The part 3349150 Flexible Hose is an essential component in various engine systems, facilitating the transfer of fluids and gases under dynamic conditions. Its application spans across multiple critical connections within the engine, ensuring efficient and reliable operation.

Connection LG STC

In the connection LG STC, the flexible hose plays a significant role in accommodating the movement and vibrations inherent in engine operation. This flexibility prevents stress and potential leaks in the connection, maintaining a consistent flow of fluids or gases. The hose’s durability under varying temperatures and pressures ensures long-term reliability in this application.

Left Bank Fuel Block Connection

For the left bank fuel block connection, the flexible hose is instrumental in delivering fuel from the fuel block to the injectors. Its flexibility allows it to withstand the engine’s vibrations without compromising the fuel supply. This ensures a steady and uninterrupted flow of fuel, which is vital for the engine’s performance and efficiency.

Left Bank Oil Control Connection

In the left bank oil control connection, the flexible hose is used to manage the flow of oil to various engine components. Its flexibility accommodates the engine’s movements, preventing oil leaks and ensuring that all parts receive the necessary lubrication. This is particularly important for maintaining the longevity and performance of engine components.

Parts and Performance

When considering parts and performance, the flexible hose contributes significantly to the overall efficiency and reliability of the engine. By providing a durable and flexible connection, it helps in reducing maintenance needs and enhancing the engine’s performance. This is especially true in high-performance engines where precision and reliability are paramount.

Performance Parts

In the context of performance parts, the flexible hose is often upgraded to meet the demands of enhanced engine performance. High-quality materials and advanced designs are used to ensure that the hose can handle increased pressures and temperatures. This upgrade is essential for maintaining the integrity of the engine’s fluid and gas pathways, directly impacting the engine’s overall performance.

Conclusion

The Cummins 3349150 Flexible Hose is a critical component in the operation of commercial trucks, particularly those equipped with K38 and K50 engines. Its design and features ensure reliable fluid transport, accommodating the dynamic conditions of engine operation. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.