This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

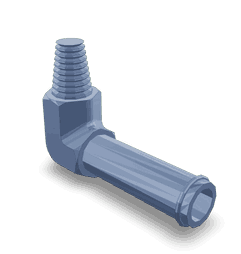

The 3353113 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial trucks. It serves a specific function within the truck’s fluid systems, facilitating the efficient transfer of fluids. Cummins, a well-established name in the industry, produces this coupling with a focus on durability and performance, ensuring it meets the demanding requirements of commercial vehicle operations.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, typically 90 degrees, allowing for a change in direction of fluid flow within a system. These couplings are integral to the fluid systems of trucks, where they enable the routing of fluids such as coolant, fuel, or hydraulic fluid through the complex network of hoses and pipes. The design of an elbow hose coupling incorporates features that ensure a secure connection, minimize the risk of leaks, and withstand the pressures and temperatures encountered in truck fluid systems 1.

Purpose of the 3353113 Elbow Hose Coupling

This Cummins part is designed to play a role in directing fluid flow within a truck’s system while maintaining the integrity of the system. It allows for a change in the direction of fluid flow, which is necessary to navigate the spatial constraints and layout of a truck’s engine compartment and fluid system routing. By providing a reliable connection point, it contributes to the overall efficiency and reliability of the truck’s fluid systems.

Key Features

The 3353113 Elbow Hose Coupling boasts several key features that enhance its durability and efficiency. It is constructed from materials that offer resistance to corrosion and wear, ensuring longevity in harsh operating environments. The design includes elements that facilitate easy installation and secure connection, reducing the likelihood of leaks. Additionally, it may feature unique attributes such as reinforced connection points or specialized coatings that further improve its performance and reliability 2.

Benefits

The advantages of using the 3353113 Elbow Hose Coupling include improved performance of the truck’s fluid systems, increased reliability due to its robust construction, and potential cost savings. The coupling’s design contributes to efficient fluid flow, which can enhance the overall operation of the truck. Its durability reduces the frequency of replacements and maintenance, leading to lower operational costs over time.

Installation Considerations

When installing the 3353113 Elbow Hose Coupling, it is important to follow guidelines and best practices to ensure a proper fit and secure connection. This includes using the necessary tools for installation, carefully aligning the coupling with the hoses, and tightening connections to the manufacturer’s specifications. Avoiding common pitfalls such as over-tightening or under-tightening can prevent damage to the coupling and ensure its effective operation.

Troubleshooting Common Issues

Common problems that may arise with the 3353113 Elbow Hose Coupling include leaks or connection failures. Troubleshooting these issues involves inspecting the coupling and connections for signs of wear or damage, ensuring that all connections are tight and secure, and checking for proper alignment. Addressing these issues promptly can prevent more serious problems and maintain the efficiency of the truck’s fluid systems.

Maintenance Tips

To ensure the long-term performance and reliability of the 3353113 Elbow Hose Coupling, regular maintenance is recommended. This includes inspecting the coupling for signs of wear or damage, cleaning it as necessary to remove any buildup that could affect its operation, and monitoring connections for leaks. Knowing when to consider replacement based on the condition of the coupling can help maintain the efficiency and safety of the truck’s fluid systems.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a history of producing reliable and high-performance components, Cummins has established itself as a leader in the field. Its focus on advancing technology and meeting the needs of commercial vehicle operators is evident in the design and manufacturing of components like the 3353113 Elbow Hose Coupling 3.

Compatibility of Elbow Hose Coupling Part 3353113 with Cummins Engines

This part is designed to fit seamlessly with a variety of Cummins engine models. It is integral in ensuring proper fluid flow and connection between different components within the engine system.

6B5.9 and 6C8.3 Engines

The 3353113 Elbow Hose Coupling is compatible with these engines, providing a reliable connection for coolant and other fluids. Its design ensures that it can withstand the operational pressures and temperatures typical of these engines.

ISB/ISD Engines

This part is engineered to fit the specific configurations of these engines, ensuring optimal performance and durability. The coupling’s precision fit helps maintain the integrity of the engine’s cooling and fluid systems.

ISBE Engines

For the ISBE engines, specifically the CM2150 SN and CM800 models, this part is a critical component. Its design allows for easy installation and secure connections, which is essential for the efficient operation of these engines.

ISBE4 and ISC Engines

The ISBE4 CM850 and ISC CM850 engines also utilize the 3353113 Elbow Hose Coupling. This part is tailored to fit the unique requirements of these engines, providing a robust connection that can endure the rigors of continuous operation.

ISL9 Engine

The ISL9 CM2150 SN engine is another model that benefits from the 3353113 Elbow Hose Coupling. This part is specifically engineered to fit the ISL9 engine’s configuration, ensuring that it can handle the high pressures and temperatures associated with this engine.

Role of Part 3353113 Elbow Hose Coupling in Engine Systems

This part is an essential component in various engine systems, facilitating the secure and efficient transfer of fluids and gases. Its application spans across multiple systems, enhancing the overall performance and reliability of the engine.

Fuel System Integration

In the fuel system, the 3353113 Elbow Hose Coupling is utilized to connect the Bosch Fuel Pump Kit to the fuel transfer lines. This coupling ensures a leak-free connection, maintaining the integrity of the fuel delivery system.

Coolant System Functionality

Within the engine coolant system, this part is employed to connect the water outlet to the engine coolant passages. This connection is vital for the circulation of coolant throughout the engine, preventing overheating and ensuring optimal operating temperatures.

Accessory and Connection Roles

This part also serves in various accessory systems, where it connects different components to the main engine systems. For instance, it is used in the Acc. (Accessory) system to link auxiliary devices such as pumps and sensors to the primary fluid lines.

Enhanced System Performance

By providing secure and flexible connections, the 3353113 Elbow Hose Coupling contributes to the enhanced performance of engine systems. It allows for easier maintenance and replacement of components, reducing downtime and improving overall engine efficiency. The coupling’s robust design ensures durability under varying operating conditions, making it a reliable component in both standard and high-performance engine applications.

Conclusion

The 3353113 Elbow Hose Coupling is a critical component in the fluid systems of commercial trucks, offering durability, efficiency, and reliability. Its design and construction are tailored to meet the demanding requirements of commercial vehicle operations, ensuring optimal performance and longevity. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall efficiency and safety of the truck’s fluid systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.