This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

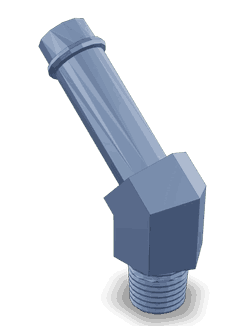

The 3354725 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established manufacturer in the automotive industry, produces a range of parts that contribute to the efficiency and reliability of commercial vehicles. This part is significant in maintaining the fluid systems within these trucks, ensuring smooth operation and longevity of the vehicle’s components 1.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used in fluid systems to connect hoses at an angle, typically 90 degrees. This design allows for flexibility in routing hoses around obstacles and within confined spaces. In the context of a truck’s systems, elbow hose couplings facilitate the transfer of fluids such as coolant, fuel, and hydraulic fluid. They operate by providing a secure connection point that can withstand the pressure and movement inherent in these systems 2.

Purpose of the 3354725 Elbow Hose Coupling

The 3354725 Elbow Hose Coupling is specifically designed to connect various fluid systems within a commercial truck. It plays a role in routing fluids efficiently between components, ensuring that systems such as the engine cooling, fuel delivery, and hydraulic systems function correctly. By handling the connection of hoses at an angle, it allows for optimal space utilization and reduces the risk of leaks or disconnections due to movement or vibration 3.

Key Features

This Cummins part is constructed from durable materials that are resistant to the pressures and temperatures encountered in commercial truck operations. Its design includes features such as a robust clamp mechanism to secure hoses firmly in place, ensuring a leak-free connection. Additionally, the coupling may incorporate corrosion-resistant coatings or materials to enhance its longevity in various operating environments.

Benefits

The advantages of the 3354725 Elbow Hose Coupling include its durability, which contributes to the reliability of the truck’s fluid systems. Its design facilitates ease of installation, reducing downtime during maintenance procedures. Furthermore, the coupling’s efficiency in fluid transfer helps maintain the performance of the truck’s systems, contributing to overall operational effectiveness.

Installation Process

Installing the 3354725 involves several steps to ensure a secure and leak-free connection. The process includes preparing the hose ends for connection, aligning the coupling with the hoses, and using the appropriate tools to clamp the hoses in place. Safety precautions, such as wearing protective gloves and ensuring the system is depressurized, should be observed throughout the installation process.

Maintenance Tips

To ensure the longevity and optimal performance of the 3354725, regular maintenance is recommended. This includes inspecting the coupling for signs of wear or damage, checking the clamp mechanism for proper tension, and cleaning the coupling to remove any debris or contaminants. Adhering to manufacturer-recommended inspection intervals will help identify potential issues before they lead to system failures.

Troubleshooting Common Issues

Common problems associated with elbow hose couplings may include leaks, disconnections, or clamp failure. Addressing these issues involves inspecting the coupling for damage, ensuring the clamp is properly tightened, and replacing any worn or damaged components. Regular maintenance and prompt attention to any signs of trouble can prevent more significant issues from arising.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industries, known for its high-quality engines and components. With a history of innovation and commitment to excellence, Cummins offers a wide range of products designed to enhance the performance and reliability of commercial vehicles. Their reputation in the industry is built on a foundation of durable, efficient, and technologically advanced solutions for the transportation sector.

Engine Compatibility with Part 3354725

The Elbow Hose Coupling part number 3354725, manufactured by Cummins, is designed to fit seamlessly within the engine systems of the 6C8.3 and C8.3 G engines. This part is integral for maintaining the integrity of the engine’s cooling and exhaust systems by ensuring a secure and leak-proof connection between hoses and the engine block.

In the 6C8.3 engine, the 3354725 is specifically engineered to connect various hoses that manage coolant flow and exhaust gases. Its precise fit ensures that the engine operates efficiently by preventing any potential leaks that could compromise the engine’s performance.

Similarly, in the C8.3 G engine, the 3354725 part is utilized to connect hoses that are critical for the engine’s cooling and exhaust systems. This coupling is designed to withstand the high temperatures and pressures typical of these engine environments, ensuring durability and reliability over time.

Both engines benefit from this part’s design, which includes features such as robust construction and precise dimensions to match the specific requirements of each engine model. This ensures that the part not only fits perfectly but also performs optimally under the demanding conditions of engine operation.

Role of Part 3354725 Elbow Hose Coupling in Engine Systems

The 3354725 Elbow Hose Coupling is a component in the integration and functionality of various engine systems. Its primary role is to facilitate the secure and efficient connection between hoses in systems where directional changes are necessary.

Block Vent Plumbing

In block vent plumbing systems, the 3354725 allows for a change in direction of the hose routing. This is particularly important in compact engine compartments where space is at a premium. The coupling ensures that the vent hoses can be routed around other components without kinking or compromising the integrity of the vent system. This maintains proper ventilation of the engine block, which is important for temperature regulation and pressure equalization.

Vent System

Within the vent system, the 3354725 plays a significant role in managing the flow of gases or fluids. By providing a reliable connection point, it ensures that the vent system can effectively release pressure build-up and prevent any potential damage to the engine components. The coupling’s design allows for smooth transitions in the vent hoses, reducing the risk of leaks and ensuring that the vent system operates efficiently.

Engine Coolant System

In the engine coolant system, the 3354725 is used to connect hoses that transport coolant to and from the engine block, radiator, and other critical components. The coupling’s ability to change the direction of the hoses is particularly beneficial in navigating the complex layout of modern engines. This ensures that coolant flows smoothly through the system, maintaining optimal engine temperature and preventing overheating. The secure connection provided by the coupling also helps in maintaining the integrity of the coolant system, reducing the risk of leaks and ensuring consistent coolant flow.

Conclusion

The 3354725 Elbow Hose Coupling is a vital component in the maintenance and operation of commercial truck fluid systems. Its robust design, ease of installation, and efficient fluid transfer capabilities contribute to the reliability and performance of these vehicles. Regular maintenance and prompt troubleshooting of common issues ensure the longevity and optimal performance of this Cummins part, underscoring its importance in the automotive industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.