This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

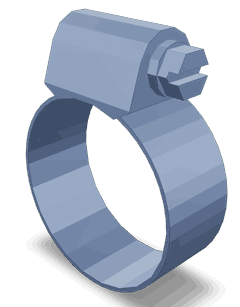

The Cummins Hose Clamp 3357147 is a component designed for use in commercial truck maintenance. Cummins, a well-established name in the commercial vehicle industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This part plays a significant role in ensuring the secure connection of hoses within various truck systems.

Basic Concepts of Hose Clamps

Hose clamps are devices used to secure hoses to fittings, ensuring a tight seal that prevents leaks and maintains system integrity. In the automotive industry, several types of hose clamps are utilized, including worm-drive, spring, and wire clamps. Each type offers specific advantages depending on the application, with worm-drive clamps being particularly favored for their ease of adjustment and strong grip 1.

Purpose of Hose Clamp 3357147 in Truck Operation

The Hose Clamp 3357147 is integral to the operation and maintenance of commercial trucks. It is applied in various systems such as fuel, coolant, and pneumatic systems, where it secures hoses to fittings. This ensures that fluids and gases are transported efficiently without leakage, contributing to the overall performance and safety of the truck 2.

Key Features of Hose Clamp 3357147

The Hose Clamp 3357147 is characterized by its robust design and material composition. Constructed from high-quality materials, it offers durability and resistance to the harsh conditions often encountered in heavy-duty applications. Its design allows for a secure grip on hoses, ensuring a reliable seal that can withstand vibrations and temperature fluctuations 3.

Benefits of Using Hose Clamp 3357147

Utilizing the Hose Clamp 3357147 provides several advantages. It enhances seal integrity, reducing the risk of leaks that can lead to system failures. The clamp is designed for ease of installation, allowing for quick and efficient setup. Additionally, its long-term reliability ensures that it can withstand the demanding environments typical of commercial truck operations 4.

Installation and Usage Guidelines

Proper installation of the Hose Clamp 3357147 involves several steps to ensure a secure and effective seal. Begin by selecting the appropriate clamp size for the hose diameter. Position the clamp around the hose and fitting, ensuring it is aligned correctly. Use a wrench to tighten the clamp gradually, avoiding over-tightening which can damage the hose. Verify the seal by checking for leaks after installation.

Troubleshooting Common Issues

Common issues with hose clamps include leaks and improper sealing. These problems can often be traced back to incorrect installation or wear and tear on the clamp. To diagnose and resolve these issues, inspect the clamp for signs of damage or misalignment. Replace the clamp if necessary, and ensure that the new clamp is installed correctly to prevent future problems.

Maintenance Tips

Regular inspection and maintenance of hose clamps are vital for ensuring ongoing performance and preventing failures. Check clamps for signs of wear, corrosion, or damage during routine maintenance checks. Replace any clamps that show signs of deterioration to maintain system integrity. Additionally, ensure that all clamps are properly tightened and aligned to prevent leaks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial vehicle industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to enhance the performance and reliability of commercial vehicles. Cummins’ commitment to quality is evident in its rigorous testing and quality control processes, ensuring that its products meet the high standards required for heavy-duty applications.

Cummins Hose Clamp 3357147 Compatibility

The Cummins Hose Clamp part number 3357147 is designed to fit a variety of Cummins engines, ensuring a secure and leak-proof connection for various hoses and lines. This part is essential for maintaining the integrity of the engine’s cooling, fuel, and exhaust systems.

Compatible Engines

- 4B3.9

- 6B5.9

- 6C8.3

- ISB CM550

- ISB CM850

- QSB5.9 44 CM550

- QSB6.7 CM850 (CM2850)

Grouping by Engine Series

The Cummins Hose Clamp 3357147 is compatible with the following engine series:

- QSB Series: QSB5.9 44 CM550, QSB6.7 CM850 (CM2850)

- ISB Series: ISB CM550, ISB CM850

- Other Models: 4B3.9, 6B5.9, 6C8.3

This hose clamp is engineered to meet the specific needs of these engines, ensuring a reliable fit and performance across different engine configurations.

Hose Clamp Component Usage in Engine Systems

The Hose Clamp, identified by part number 3357147, is an essential component in ensuring the secure and efficient operation of various engine systems. Its role is to maintain the integrity of hose connections, preventing leaks and ensuring optimal performance across several key components.

Compressor Air Inlet

In the compressor air inlet system, the Hose Clamp secures the hoses that deliver air to the compressor. This ensures a consistent airflow, which is vital for the compressor’s efficiency and the overall performance of the engine. A secure connection prevents air leaks, which could otherwise lead to reduced compressor efficiency and increased energy consumption.

Breather System

Within the breather system, the Hose Clamp plays a significant role in maintaining the seal of the breather hoses. These hoses allow for the release of pressure and contaminants from the crankcase. A well-sealed breather system ensures that the crankcase ventilation operates effectively, contributing to the engine’s longevity and performance.

Crankcase Ventilation

The Hose Clamp is also integral to the crankcase ventilation system. By securing the hoses that connect to the crankcase, it ensures that gases and moisture are properly vented. This helps in maintaining the crankcase pressure within optimal levels, which is essential for the engine’s smooth operation and durability.

PDC (Positive Displacement Compressor) Kit

In the context of a PDC kit, the Hose Clamp is used to secure various hoses that are part of the kit’s arrangement. This includes hoses that connect to the compressor and other components within the kit. Ensuring these connections are tight and leak-free is essential for the kit’s performance and the efficiency of the overall system.

General Arrangement

Across the general arrangement of engine systems, the Hose Clamp is a ubiquitous component. It is used to secure hoses in a variety of applications, from fuel lines to coolant systems. Its role in maintaining the integrity of these connections is fundamental to the safe and efficient operation of the engine.

Conclusion

The Cummins Hose Clamp 3357147 is a critical component in the maintenance and operation of commercial trucks. Its robust design, ease of installation, and long-term reliability make it an essential part for securing hose connections in various engine systems. Regular maintenance and proper installation are key to ensuring the ongoing performance and safety of these systems.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan, Avinash Kumar Agarwal, Springer, 2019.

↩ -

Fundamentals of Vehicle Dynamics, Thomas D. Gillespie, SAE International, 2021.

↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.