This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

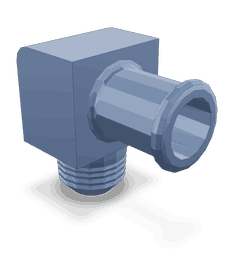

The 3395549 Elbow Hose Coupling, manufactured by Cummins, is a component designed for use in commercial truck systems. Cummins, a well-established name in the automotive industry, produces a range of parts that contribute to the efficiency and reliability of heavy-duty vehicles. This part is significant in maintaining the integrity of fluid systems within these trucks.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, facilitating the transfer of fluids in systems where direct alignment is not feasible. These couplings are integral to fluid systems, allowing for flexible routing of hoses around obstacles and within confined spaces. In a truck’s infrastructure, they enable the efficient conveyance of fluids such as coolant, fuel, or hydraulic lines, ensuring that these systems operate smoothly and effectively 1.

Purpose of the 3395549 Elbow Hose Coupling

The 3395549 Elbow Hose Coupling is specifically designed to play a role in the operation of commercial trucks by connecting hoses at an angle within various fluid systems. Its application extends to coolant systems, where it aids in the circulation of coolant to regulate engine temperature, fuel systems for delivering fuel to the engine, and hydraulic systems that power various truck functions. By providing a secure and angled connection, this coupling ensures that fluid flow is maintained even when hoses cannot be aligned directly 2.

Key Features

The 3395549 incorporates several design elements and material properties that enhance its performance and durability. These include corrosion resistance to withstand exposure to various fluids and environmental conditions, pressure ratings that ensure it can handle the specific pressures within the system it serves, and connection types that are compatible with standard hose sizes and fittings used in commercial trucks. These features contribute to the coupling’s reliability and longevity in demanding applications 3.

Benefits

The advantages provided by the 3395549 include improved system reliability through secure and durable connections, ease of installation due to its design, and maintenance efficiency as a result of its robust construction. These benefits contribute to the overall performance and uptime of commercial trucks, making the coupling a valuable component in their fluid systems.

Installation Considerations

For the proper installation of the 3395549, it is important to follow guidelines that include adhering to torque specifications to ensure connections are secure without overtightening, alignment procedures to maintain the integrity of the fluid path, and compatibility with other system components to ensure seamless integration. Proper installation is key to the coupling’s performance and the system’s reliability.

Troubleshooting Common Issues

Typical problems associated with elbow hose couplings, such as leaks or disconnections, can often be traced to installation errors or wear and tear. Recommended troubleshooting steps include checking for proper alignment and torque, inspecting for signs of wear or damage, and ensuring compatibility with system components. Addressing these issues promptly can prevent system failures and maintain the efficiency of the truck’s fluid systems.

Maintenance Practices

Recommended maintenance routines for the 3395549 include regular inspection intervals to check for signs of wear, corrosion, or damage, cleaning procedures to remove any buildup that could affect performance, and considering replacement when signs of significant wear or failure are present. Adhering to these maintenance practices can extend the life of the coupling and ensure the continued reliability of the truck’s fluid systems.

Compatibility of 3395549 with Cummins Engines

The 3395549 is designed to fit seamlessly with a variety of Cummins engines. This part is integral in ensuring the proper connection and functionality of the engine’s hose systems. Here is a detailed look at its compatibility with specific Cummins engine models:

G5.9 and G8.3 Engines

The 3395549 is engineered to integrate smoothly with the G5.9 and G8.3 engines. These engines are known for their reliability and efficiency, and the coupling ensures that the hose connections maintain their integrity under operational conditions.

G855 and GTA855 CM558 (CM2358) Engines

For the G855 and GTA855 CM558 (CM2358) engines, the 3395549 plays a role in the hose system. These engines are part of Cummins’ advanced lineup, designed for heavy-duty applications. The coupling’s design ensures that it fits perfectly, providing a secure and leak-proof connection.

G101 and N14 G Engines

The 3395549 is also compatible with the G101 and N14 G engines. These engines are widely used in various industries due to their robust performance and durability. The coupling’s fit ensures that the hose connections remain stable, even under high-stress conditions.

Grouping by Application

The compatibility of the 3395549 across these engines can be grouped based on their typical applications:

- Industrial and Heavy-Duty Applications: G5.9, G8.3, G855, GTA855 CM558 (CM2358), G101

- Medium-Duty Applications: N14 G

This grouping helps users identify the appropriate engines for which the part is suitable, ensuring optimal performance and reliability.

Role of 3395549 in Engine Systems

The 3395549 is an essential component in various engine systems, facilitating the secure and efficient connection of hoses in multiple applications.

In the breather system, the elbow hose coupling ensures a reliable connection between the breather hose and the crankcase. This connection allows for the release of pressure and contaminants from the crankcase, maintaining optimal engine performance and longevity.

Within the crankcase ventilation system, the coupling plays a part in connecting hoses that route gases from the crankcase to the intake manifold. This process helps in reducing emissions and improving engine efficiency.

In systems involving a module or fuel control unit, the elbow hose coupling is used to connect hoses that supply fuel or other fluids to and from the module. This ensures a consistent and uninterrupted flow, which is vital for the module’s operation and the overall fuel delivery system.

For plumbing applications in engine systems, the coupling is instrumental in connecting various hoses that transport fluids such as coolant, oil, or hydraulic fluid. This ensures that these fluids are delivered to their respective components without leaks or disruptions.

In the cabin heater system, the elbow hose coupling connects hoses that circulate hot coolant from the engine to the heater core. This connection is essential for providing warm air to the cabin, enhancing passenger comfort.

When integrated with a valve or pressure regulator, the coupling helps in maintaining the integrity of the hose connections. This is particularly important in systems where precise fluid control and pressure maintenance are required.

Overall, the 3395549 serves as a versatile and reliable component in various engine systems, ensuring that hoses are securely connected and fluids are efficiently transported.

Conclusion

The 3395549 Elbow Hose Coupling is a critical component in the fluid systems of commercial trucks, offering reliable and efficient connections for hoses in various applications. Its design and features contribute to the overall performance and reliability of the vehicles it serves. Proper installation, maintenance, and troubleshooting practices are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.