This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3408207 Flexible Hose is a component designed for use in commercial truck operations. It serves a specific function within the truck’s system, contributing to the efficient operation of various subsystems. Understanding its purpose and significance can help in maintaining the overall performance and reliability of commercial trucks.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to connect different components, allowing for movement and vibration without compromising the integrity of the connection. They are typically made from materials that offer flexibility, durability, and resistance to the fluids they transport. In automotive applications, flexible hoses play a role in connecting parts of the engine, cooling, and fuel systems, among others 1.

Purpose of the Cummins 3408207 Flexible Hose

This Cummins part is designed to connect specific components within a commercial truck’s system. It facilitates the transport of fluids, contributing to the operation of the truck’s subsystems. By providing a flexible connection, it accommodates the movement and vibration inherent in truck operations, ensuring a secure and reliable fluid transfer between components.

Key Features

The 3408207 incorporates several key features that enhance its performance and longevity. These include a material composition that offers flexibility and durability, allowing it to withstand the pressures and temperatures of the fluids it transports. Its design characteristics are tailored to ensure a secure fit with connected components, reducing the risk of leaks and enhancing overall system reliability.

Benefits

The use of this part offers several benefits. Its flexibility allows for accommodation of the movement and vibration typical in truck operations, reducing stress on connected components. The hose’s design helps minimize the risk of leaks, contributing to system integrity. Additionally, its durability ensures long-term performance, and its ease of installation compared to rigid hoses can simplify maintenance procedures 2.

Installation Considerations

When installing the 3408207, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the correct fitting techniques to secure the hose to connected components, ensuring alignment is correct to prevent stress on the hose, and verifying that all connections are tight to prevent leaks.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these problems, regular inspections can help identify wear or damage early. For leaks, checking connections and ensuring they are tight can often resolve the issue. Kinks may require adjusting the hose’s routing to ensure it lies smoothly without bends that could restrict flow. Degradation might indicate the need for replacement to maintain system performance and safety 3.

Maintenance Tips

Regular maintenance of the 3408207 is key to ensuring optimal performance and safety. This includes periodic inspections to check for signs of wear, damage, or leaks. Cleaning the hose as part of routine maintenance can help remove contaminants that might affect its performance. Knowing when to replace the hose, based on signs of significant wear or degradation, is also important for maintaining system integrity.

Role of 3408207 Flexible Hose in Plumbing and Turbocharger Systems

In the realm of automotive and industrial engineering, the 3408207 serves as a vital connector in both plumbing and turbocharger systems.

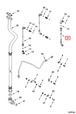

Plumbing Systems

In plumbing applications, the Flexible Hose is employed to link various components, ensuring a secure and leak-free connection. Its flexibility allows it to accommodate the natural expansion and contraction of pipes due to temperature fluctuations, thereby maintaining system integrity. This hose is often used to connect water supply lines to appliances, ensuring a consistent flow of water while withstanding the pressure variations typical in plumbing systems.

Turbocharger Systems

Within turbocharger systems, the 3408207 plays a significant role in connecting the turbocharger to the engine’s intake and exhaust manifolds. This connection is essential for the efficient transfer of exhaust gases, which drive the turbine within the turbocharger. The hose’s flexibility is particularly beneficial in this application, as it can absorb the vibrations and movements inherent in the engine’s operation, thus protecting the more rigid components from undue stress. Additionally, the hose helps in managing the high temperatures and pressures associated with exhaust gases, contributing to the overall performance and durability of the turbocharger system.

About Cummins

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines, related technologies, and complete power solutions for most applications, demonstrating a strong dedication to advancing the technology that powers the world.

Conclusion

The Cummins 3408207 Flexible Hose is a critical component in the efficient operation of commercial trucks, offering flexibility, durability, and ease of installation. Its role in both plumbing and turbocharger systems highlights its versatility and importance in maintaining system integrity and performance. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.