This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

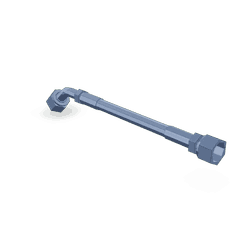

The Cummins 3408235 Flexible Hose is a component designed for use in commercial trucks. It serves a significant role in the operation of these vehicles by facilitating the transfer of fluids between various systems. This hose is engineered to withstand the demanding conditions encountered in commercial trucking, ensuring reliable performance and longevity.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized in automotive systems to connect different components, allowing for movement and vibration without compromising the integrity of the fluid transfer. They are typically made from materials that offer flexibility, durability, and resistance to the fluids they transport. In automotive applications, flexible hoses are used in fuel, coolant, brake, and hydraulic systems, among others 1.

Purpose of the Cummins 3408235 Flexible Hose

The Cummins 3408235 Flexible Hose is specifically designed to connect components within a truck’s system, facilitating the transport of fluids. It plays a role in accommodating the movement and vibration inherent in truck operations, ensuring a secure and reliable connection between parts that may not be fixed in position relative to each other.

Key Features

This Cummins part boasts several key features that enhance its performance. These include a material composition that offers flexibility and durability, allowing it to withstand the pressures and temperatures of the fluids it transports. Its design characteristics are tailored to provide a secure fit and easy installation, while also accommodating the dynamic environment of a commercial truck.

Benefits

The use of the Cummins 3408235 Flexible Hose offers several benefits. Its flexibility reduces the risk of leaks by accommodating movement and vibration, which rigid hoses may not handle as effectively. The hose’s durability ensures long-term reliability, and its design facilitates ease of installation compared to more rigid alternatives.

Installation Considerations

When installing this part, it is important to follow guidelines and best practices to ensure optimal performance. This includes proper routing to avoid sharp bends or kinks, securing the hose in place to prevent movement that could lead to wear or damage, and ensuring compatibility with other system components to maintain the integrity of the fluid transfer system.

Troubleshooting Common Issues

Common issues with flexible hoses may include leaks, kinks, or degradation over time. To address these problems, it is important to regularly inspect the hose for signs of wear or damage, such as cracks, bulges, or soft spots. If issues are identified, the hose should be replaced to prevent fluid leaks or system failure.

Maintenance Tips

Regular maintenance of the Cummins 3408235 Flexible Hose is key to prolonging its service life. This includes inspecting the hose at recommended intervals for signs of wear or damage, cleaning the hose and its connections to remove any buildup that could impede fluid flow, and taking preventive measures such as avoiding sharp bends during installation to reduce stress on the hose.

Role in Enhancing System Performance

The Cummins 3408235 Flexible Hose contributes to the overall performance and reliability of a truck’s systems by providing a flexible and durable connection that accommodates movement and vibration. This ensures that fluids are transported efficiently and reliably, even under the demanding conditions encountered in commercial trucking.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor locations and approximately 6,700 dealer locations.

Cummins Part 3408235 Flexible Hose Compatibility

This part is designed to fit seamlessly with several engine models. It is crucial for maintaining the integrity of fluid systems within the engines, ensuring smooth operation and preventing leaks.

QSC8.3 CM850 (CM2850) Engines

The Flexible Hose part 3408235 is specifically engineered to integrate with the QSC8.3 CM850 (CM2850) engines. This compatibility ensures that the hose can withstand the operational demands of these engines, providing a reliable connection for various fluid lines. The design of the hose accommodates the unique layout and requirements of these engines, ensuring that it fits perfectly without compromising performance.

Grouping of Engines

For the QSC8.3 CM850 (CM2850) engines, the Flexible Hose part 3408235 is a critical component that fits into the broader family of Cummins engines. This grouping highlights the versatility and robustness of the part, making it suitable for a range of applications within these engine models. The design considerations for this hose ensure that it meets the specific needs of these engines, providing a seamless fit and reliable performance.

Role of Part 3408235 Flexible Hose in Various Engine Systems

Fuel System Integration

In the fuel system, the 3408235 Flexible Hose serves as a vital conduit for the transfer of fuel from the fuel tank to the engine. It is engineered to withstand the pressures and temperatures associated with fuel delivery, ensuring a consistent and reliable flow. This hose is typically connected to the fuel pump on one end and the fuel injectors or carburetor on the other, facilitating the seamless movement of fuel. Its flexibility allows it to navigate the contours of the engine bay, avoiding sharp edges and moving components.

Filter System Connection

When integrated with the filter system, the 3408235 Flexible Hose plays a key role in maintaining the integrity of the filtration process. It connects the fuel filter to the fuel lines, ensuring that clean fuel is delivered to the engine. The hose’s material is selected to be compatible with the fuel type, preventing degradation or permeability issues that could compromise filtration efficiency. This connection is essential for protecting the engine from contaminants that could lead to wear or failure.

Plumbing Applications

In plumbing applications within the engine system, the 3408235 Flexible Hose is used to transport various fluids, including coolant and oil. For coolant systems, the hose ensures that the engine maintains optimal operating temperatures by efficiently circulating coolant between the engine block and the radiator. In oil systems, it facilitates the flow of lubricant to and from the engine components, reducing friction and wear. The hose’s flexibility and durability are paramount in withstanding the dynamic environment of the engine compartment.

Crankcase Breather System

The 3408235 Flexible Hose is also employed in the crankcase breather system, where it helps manage the pressure within the crankcase. By connecting the crankcase to the intake tract or a ventilation system, the hose allows for the safe release of gases and vapors produced during combustion. This prevents the buildup of pressure that could lead to oil leaks or engine damage. The hose’s design must accommodate the varying pressures and temperatures within the crankcase, ensuring reliable performance over the engine’s lifespan.

Conclusion

The Cummins 3408235 Flexible Hose is a critical component in the operation of commercial trucks, ensuring the efficient and reliable transfer of fluids across various systems. Its design, featuring flexibility, durability, and compatibility with a range of engine models, makes it an essential part for maintaining the performance and longevity of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this part, contributing to the overall reliability and efficiency of the vehicle’s systems.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.