This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

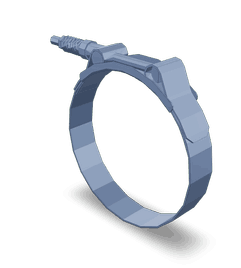

The Hose Clamp 3410463, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its high-quality parts and engines. This Cummins part is significant in ensuring the secure and efficient operation of various truck systems by maintaining the integrity of hose connections.

Basic Concepts of Hose Clamps

Hose clamps are mechanical devices used to secure hoses to fittings, ensuring a tight and leak-free connection. They come in various types, including worm-drive, spring, and screw-type clamps, each suited to different applications based on the specific requirements of the system. Hose clamps play a vital role in preventing fluid leaks, which can lead to system failures and safety hazards 1.

Purpose of Hose Clamp 3410463

This part is designed to secure hoses in commercial truck applications, ensuring that connections remain tight under varying conditions. It is used in various truck systems, including fuel, coolant, and hydraulic lines. By maintaining a secure fit, the clamp helps prevent leaks and ensures the efficient transfer of fluids, contributing to the overall reliability of the truck’s systems.

Key Features

This part boasts several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The design includes a worm-drive mechanism, which allows for precise adjustment and a strong grip on the hose. Additionally, the clamp features a band made from stainless steel, providing excellent strength and flexibility.

Benefits

Using this Cummins part offers several advantages. Its robust construction and precise adjustment mechanism contribute to improved reliability and reduced maintenance needs. The ease of installation, thanks to its worm-drive design, allows for quick and efficient setup. Furthermore, its durability ensures long-term performance, even in demanding commercial truck environments.

Installation Process

Proper installation of this part is crucial for its effective performance. Begin by ensuring the hose is clean and free from debris. Place the clamp around the hose and fitting, ensuring it is aligned correctly. Use the worm-drive mechanism to tighten the clamp gradually, achieving a secure fit without over-tightening, which could damage the hose. Verify the connection by checking for leaks and ensuring the clamp is snug.

Troubleshooting Common Issues

Common issues with hose clamps include leaks, loose connections, and corrosion. Leaks may indicate an improper fit or damage to the hose. Ensuring the clamp is correctly installed and the hose is in good condition can mitigate this issue. Loose connections can be addressed by re-tightening the clamp. Corrosion may be prevented by using clamps made from corrosion-resistant materials and regularly inspecting the components 2.

Maintenance Tips

Regular maintenance of this part is important for its longevity and effectiveness. Inspect the clamp and hose regularly for signs of wear, corrosion, or damage. Ensure the clamp remains tight and replace any worn or damaged components promptly. Following these maintenance practices will help ensure the clamp continues to perform reliably.

Compatibility and Applications

This part is designed for use in various commercial truck applications, including fuel, coolant, and hydraulic systems. It is compatible with a range of hose sizes and types, making it a versatile component for different truck models and systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability. The company offers a comprehensive range of products for on-highway, off-highway, and stationary applications, maintaining a strong reputation in the commercial truck industry.

Cummins Hose Clamp 3410463 Compatibility

This Cummins part is a critical component designed to secure hoses in various engine systems. This part is engineered to ensure a tight and reliable seal, preventing leaks and maintaining system integrity. It is compatible with several Cummins engine models, including:

- QSK60 CM500

This hose clamp is essential for maintaining the performance and safety of these engines by ensuring that hoses remain securely attached under various operating conditions. Its robust design and high-quality materials make it a reliable choice for use in demanding environments.

Role of Part 3410463 Hose Clamp in Engine Systems

This part is instrumental in maintaining the integrity and efficiency of various engine systems. In the context of an aftercooler system, this hose clamp ensures a secure connection between the aftercooler and the associated hoses. This is vital for the proper circulation of coolant, which is essential for reducing the temperature of compressed air before it enters the engine’s combustion chamber. A well-sealed connection prevents leaks and maintains the efficiency of the cooling process, thereby optimizing engine performance.

In a turbocharger arrangement, this part plays a significant role by securing the hoses that connect the turbocharger to the intercooler and other components. This ensures that the pressurized air from the turbocharger is efficiently channeled through the system without any loss of pressure or leaks. The secure fit provided by the hose clamp is essential for maintaining the turbocharger’s efficiency, which directly impacts the engine’s power output and fuel efficiency.

Overall, this part is a key component in ensuring that these engine systems operate smoothly and efficiently, contributing to the overall performance and reliability of the engine 3.

Conclusion

The Hose Clamp 3410463 by Cummins is a vital component in the maintenance and efficiency of commercial truck systems. Its robust design, ease of installation, and compatibility with various engine models make it an essential part for ensuring secure and leak-free hose connections. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Saiful Bari, Diesel Engine Combustion, Emissions and Condition Monitoring, InTech, 2013.

↩ -

David C Barton and John D Fieldhouse, Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, Elsevier, 2009.

↩ -

Pawel Drozdziel, The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects, Routledge, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.