3410941

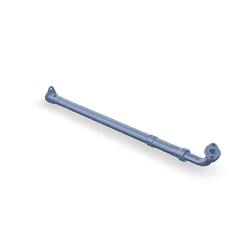

Flexible Hose

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3410941 Flexible Hose is a critical component in commercial trucks, essential for the efficient operation of various vehicle systems. This hose ensures the functionality and reliability of truck operations by facilitating the transport of fluids and gases between components that may move or vibrate during operation.

Basic Concepts of Flexible Hoses

Flexible hoses are designed to transport fluids or gases between different parts of a system, accommodating movement and vibration. In automotive applications, these hoses connect components that are not fixed in position relative to each other. They are typically made from materials such as rubber, thermoplastic, or metal braids, chosen for their flexibility, durability, and resistance to environmental conditions, including temperature variations and chemical exposure 1.

Purpose of the 3410941 Flexible Hose

The Cummins 3410941 Flexible Hose is designed to connect components within a truck’s operational systems, facilitating the transport of fluids or gases. It is engineered to withstand the dynamic environment of a commercial truck, ensuring a secure and reliable connection between moving or vibrating parts 3.

Key Features

The 3410941 Flexible Hose incorporates several design elements and materials that enhance its performance and durability. These may include reinforced construction to resist pressure and abrasion, materials selected for their flexibility and resistance to environmental factors, and unique characteristics such as anti-kink features or specialized end fittings that ensure a secure connection to the systems it serves 2.

Benefits

Utilizing the 3410941 Flexible Hose in truck applications offers several advantages. Its design allows for improved flexibility, enabling it to accommodate the movement and vibration inherent in truck operations. Additionally, the hose’s construction provides resistance to wear and tear, contributing to its longevity. It also performs well across a range of temperatures, ensuring reliable operation in various conditions 1.

Installation Considerations

When installing the 3410941 Flexible Hose, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes ensuring proper alignment with the components it connects, using appropriate securing methods to maintain a stable connection, and verifying compatibility with the existing systems to prevent issues such as leaks or reduced performance 3.

Troubleshooting Common Issues

Common problems associated with flexible hoses, including the 3410941, may include leaks, kinks, or degradation over time. Troubleshooting these issues involves inspecting the hose for signs of wear or damage, checking connections for proper alignment and security, and addressing any environmental factors that may contribute to hose degradation 2.

Maintenance Tips

To ensure the longevity and optimal performance of the 3410941 Flexible Hose, regular maintenance is recommended. This includes conducting periodic inspections for signs of wear or damage, cleaning the hose as necessary to remove contaminants that may affect its performance, and adhering to replacement schedules based on the hose’s condition and the manufacturer’s recommendations 1.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in producing truck components. With a history of developing reliable and efficient solutions for the transportation sector, Cummins continues to play a significant role in advancing the technology and performance of commercial vehicles 3.

Role of Part 3410941 Flexible Hose in Engine Systems

The 3410941 Flexible Hose is an essential component in various engine systems, facilitating the efficient transfer of fluids and gases under dynamic conditions. Its application spans across multiple systems, including plumbing and turbocharger setups.

Plumbing Systems

In plumbing applications, the 3410941 Flexible Hose allows for the conveyance of fluids such as coolant, fuel, and hydraulic fluids. Its flexibility accommodates the vibrations and movements inherent in engine operations, ensuring a secure and leak-free connection between rigid plumbing components. This adaptability is particularly beneficial in high-stress environments where traditional rigid pipes might fail due to constant motion and thermal expansion 1.

Turbocharger Systems

When integrated into turbocharger systems, the 3410941 Flexible Hose plays a significant role in managing the flow of turbocharger oil. Turbochargers operate at extremely high speeds, generating substantial heat and vibration. The hose’s flexibility mitigates the mechanical stress on the oil lines, preventing cracks and leaks that could lead to oil starvation and subsequent turbocharger failure. Additionally, its resistance to high temperatures and pressures ensures consistent oil delivery, maintaining the turbocharger’s lubrication and cooling efficiency 2.

Turbocharger Oil Systems

In turbocharger oil systems, the 3410941 Flexible Hose is employed to connect the turbocharger to the engine’s oil supply and return lines. This connection is vital for the proper lubrication of the turbocharger’s bearings and the cooling of its components. The hose’s design allows it to withstand the high-pressure oil flow and the thermal fluctuations typical in turbocharger applications, ensuring reliable performance and durability 3.

Conclusion

The 3410941 Flexible Hose by Cummins is a versatile and robust component designed to enhance the functionality and reliability of commercial truck engine systems. Its flexibility, durability, and resistance to environmental conditions make it an essential part for the efficient transfer of fluids and gases in dynamic environments. Regular maintenance and proper installation are key to ensuring its longevity and optimal performance.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ ↩ ↩ ↩ -

Gasoline Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2015.

↩ ↩ ↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.