This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

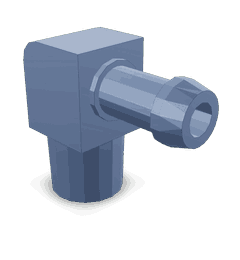

The Elbow Hose Coupling 3528121, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This part plays a role in ensuring the smooth operation of various truck systems.

Basic Concepts of Elbow Hose Couplings

An elbow hose coupling is a fitting used to connect hoses at an angle, typically 90 degrees, allowing for fluid transfer in systems where space constraints or design requirements necessitate a change in direction. These couplings are integral to fluid systems, facilitating the movement of liquids or gases between components without leakage. In the context of a truck, they are used in various systems including cooling, fuel, and hydraulic systems, ensuring that fluids are directed efficiently and securely 1.

Purpose of the 3528121 Elbow Hose Coupling

This Cummins part is specifically designed to serve multiple functions within a truck’s systems. In the cooling system, it aids in directing coolant flow to and from the engine, radiator, and other components. Within the fuel system, it ensures that fuel is delivered from the tank to the engine under various driving conditions. Additionally, in hydraulic systems, it plays a role in transferring hydraulic fluid to operate various truck mechanisms. Its application across these systems underscores its versatility and importance in maintaining truck performance 2.

Key Features

The 3528121 is constructed with materials that offer durability and resistance to the harsh conditions encountered in commercial truck operations. It typically features a robust metal body with corrosion-resistant properties, ensuring longevity. The coupling includes secure connection types, such as barb or clamp connections, to prevent leaks and ensure a tight fit. Unique attributes may include reinforced hose ends or specialized coatings that enhance performance and durability in demanding environments.

Benefits

Utilizing the 3528121 offers several advantages. It provides improved fluid flow due to its design, which minimizes restrictions. The secure connection types reduce the likelihood of leaks, contributing to system efficiency. Its durable construction enhances the overall reliability of the truck’s fluid systems. Additionally, the coupling is designed for ease of installation, allowing for quick and straightforward replacement or integration into existing systems.

Installation Process

Installing the 3528121 requires careful preparation and the use of appropriate tools. Begin by ensuring the hoses are clean and free of debris. Use the correct tools to connect the coupling to the hoses, ensuring a snug fit without over-tightening, which could damage the components. Follow the manufacturer’s guidelines for torque specifications to secure the connections properly. Testing the system for leaks after installation is a best practice to ensure a secure and efficient connection.

Maintenance Tips

To prolong the life of the 3528121, regular maintenance is recommended. Inspect the coupling and connected hoses at routine intervals for signs of wear, corrosion, or leaks. Cleaning the coupling and surrounding areas can prevent the buildup of contaminants that may affect performance. If any damage or significant wear is observed, consider replacement to maintain system integrity and efficiency.

Troubleshooting Common Issues

Common issues with elbow hose couplings include leaks or connection failures. These can often be traced to improper installation, wear and tear, or environmental factors. To troubleshoot, first, ensure all connections are secure and properly torqued. Inspect for signs of wear or damage to the coupling or hoses. Addressing these issues promptly can prevent more significant problems and ensure the continued efficient operation of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to enhance the performance, efficiency, and reliability of commercial vehicles. The 3528121 Elbow Hose Coupling is a testament to Cummins’ commitment to providing high-quality components for the heavy-duty truck market.

Compatibility of Elbow Hose Coupling Part 3528121 with Cummins Engines

This part is designed to fit a variety of Cummins engines. This comprehensive compatibility ensures that the Elbow Hose Coupling can be used across a wide range of Cummins engines, providing a reliable solution for maintaining fluid and gas transfer within the engine system.

Cummins B Series Engines

- 4B3.9

- 6B5.9

Cummins C Series Engines

- 6C8.3

Cummins B6.7 Series Engines

- B6.7S

Cummins ISB Series Engines

- ISB CM550

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B127

Cummins ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

Cummins ISC Series Engines

- ISC CM554

- ISC CM850

Cummins ISG Series Engines

- ISG11 CM2880 G108

- ISG12 CM2880 G107

Cummins ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

Cummins ISM Series Engines

- ISM11 CM876 SN

Cummins ISX Series Engines

- ISX CM570

- ISX CM870

Cummins ISZ Series Engines

- ISZ13 CM2150 Z105

Cummins L Series Engines

- L8.9

- L8.9 CM2670 L134C

Role of Part 3528121 Elbow Hose Coupling in Engine Systems

The 3528121 is an essential component in various engine systems, particularly those involving turbochargers and their associated assemblies. This coupling facilitates the secure and efficient connection between different hoses and components, ensuring optimal performance and reliability.

Integration with Turbocharger Systems

In turbocharger setups, the 3528121 is often used to connect the turbocharger actuator to the air fuel control plumbing. This connection is vital for regulating the airflow and fuel mixture, which directly impacts the engine’s performance and efficiency. The coupling ensures a leak-free connection, maintaining the integrity of the air fuel ratio.

Application in Compressor and Turbine Housings

When dealing with compressor housings and turbine housings, the 3528121 plays a role in linking various hoses that manage the airflow through these components. Proper connection is necessary to prevent any loss of pressure or efficiency, which could otherwise lead to reduced performance of the turbocharger.

Use in Aftermarket and Performance Parts

For aftermarket turbochargers and performance parts, the 3528121 is frequently employed to enhance the connectivity between different elements of the turbocharger kit. Whether it’s a pre-set turbine housing kit or a turbocharger actuator kit, this coupling ensures that all components work in unison, providing the desired boost and performance enhancements.

Connection in Turbocharger Actuator and Wastegate Systems

In systems involving turbocharger actuators and wastegate actuator kits, the 3528121 is used to connect the actuator to the wastegate. This connection is important for managing the exhaust gas flow, which in turn controls the turbocharger’s speed and the engine’s overall performance.

Role in Turbocharger Campaign Kits

Turbocharger campaign kits often include the 3528121 to ensure all upgraded components are properly connected. This is particularly important in ensuring that the upgraded turbocharger, whether it’s an ISL-Uprate or any other model, functions correctly within the engine system.

Protective Cover and Core Assembly Applications

In scenarios where a protective cover or core assembly is part of the turbocharger system, the 3528121 is used to connect hoses that may run through or around these protective elements. This ensures that the hoses are securely in place and can withstand the operational conditions without failure.

General Use in Turbocharger Kits

Across various turbocharger kits, including those designed for specific engine models or performance levels, the 3528121 is a standard component. It provides the necessary flexibility and secure connection required for the complex hose routing often found in turbocharged engine systems.

Conclusion

The 3528121 Elbow Hose Coupling by Cummins is a versatile and essential component in the operation of commercial trucks. Its role in ensuring secure and efficient fluid transfer across various systems highlights its importance in maintaining the performance and reliability of heavy-duty vehicles. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.