3535215

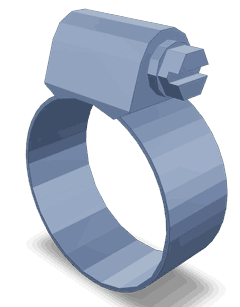

Hose Clamp

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3535215 Hose Clamp is a vital component designed to secure hoses in various systems within commercial trucks. Its role is significant in maintaining the integrity and efficiency of these systems, ensuring that fluids and gases are transported without leaks or disruptions.

Basic Concepts of Hose Clamps

Hose clamps are devices used to create a secure connection between a hose and a fitting. They function by applying even pressure around the hose, ensuring a tight seal. Commonly constructed from materials such as metal, plastic, or rubber, hose clamps are chosen based on the specific requirements of the application, including the type of hose, the environment, and the fluids or gases being transported 1.

Purpose of the Cummins 3535215 Hose Clamp

The Cummins 3535215 Hose Clamp is utilized in several critical systems within commercial trucks, including fuel, coolant, and air brake systems. It plays a role in these systems by ensuring that hoses remain securely attached to their fittings, preventing leaks and maintaining system efficiency. This clamp is particularly important in environments where vibrations and temperature fluctuations are common, as it helps to maintain a consistent and reliable connection 2.

Key Features

The Cummins 3535215 Hose Clamp is characterized by its robust design and material composition. Typically made from durable materials, it is engineered to withstand the rigors of commercial truck operations. Unique attributes of this clamp include its ease of installation, adjustable band for a custom fit, and resistance to corrosion and extreme temperatures, which enhance its performance and durability 3.

Benefits of Using the Cummins 3535215 Hose Clamp

Utilizing the Cummins 3535215 Hose Clamp offers several advantages. It provides improved seal integrity, reducing the risk of leaks in critical systems. Its design allows for easy installation, minimizing downtime during maintenance procedures. Additionally, the clamp’s resistance to environmental factors ensures longevity and reliability in various operating conditions 4.

Installation Process

To install the Cummins 3535215 Hose Clamp, first, ensure the hose and fitting are clean and free of debris. Slide the clamp onto the hose, positioning it near the fitting. Once in place, use the appropriate tool to tighten the clamp until it achieves the desired tension, ensuring a secure seal without over-tightening, which could damage the hose.

Troubleshooting Common Issues

Common issues with hose clamps include leaks due to improper sealing or clamp failure. To address these, first, inspect the clamp and hose for signs of wear or damage. Ensure the clamp is correctly positioned and tightened. If leaks persist, consider replacing the clamp or hose as necessary to restore system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3535215 Hose Clamp involves periodic inspection for signs of wear, corrosion, or damage. It is advisable to check the clamp’s tension and adjust as needed to maintain a secure seal. Additionally, cleaning the clamp and surrounding areas can prevent buildup that may affect performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation 5.

Cummins Hose Clamp 3535215 Compatibility

The Cummins Hose Clamp 3535215 is designed to fit a variety of Cummins engines, ensuring a secure and reliable connection for hoses and other components. This part is engineered to meet the rigorous standards set by Cummins, providing durability and ease of installation across multiple engine models.

Compatible Engines

- 15N CM2380 M104B

- 4B3.9

- 6B5.9

- 6C8.3

- B3.3

- B4.5

- B5.6 CM2670 B152B

- B5.9 CM2670 B166C

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7S

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

- F3.8 F102

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- ISB CM550

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB3.9 CM2220 B107

- ISB5.9 CM2880 B110

This hose clamp is engineered to provide a tight and secure fit, preventing leaks and ensuring the integrity of the engine’s cooling and fuel systems. It is compatible with the listed engines, making it a versatile choice for maintenance and repair.

Role of Part 3535215 Hose Clamp in Engine Systems

The part 3535215 Hose Clamp is a critical component in maintaining the integrity and efficiency of various engine systems. It ensures secure connections between hoses and components, preventing leaks and maintaining optimal pressure levels.

Integration with Actuator Kits

In actuator kits, the Hose Clamp secures hoses that connect to the actuator, ensuring a tight seal. This is particularly important in systems where precise control of actuator movement is required, such as in turbochargers or wastegates. A secure connection prevents air or fluid leaks, which could otherwise lead to inefficient actuator performance.

Application in Turbocharger Systems

For turbochargers, the Hose Clamp is used to connect hoses in the turbocharger actuator kit and turbocharger gasket kit. It ensures that the hoses remain firmly attached to the turbocharger housing and other components, maintaining the necessary pressure and flow rates for efficient turbo operation.

Use in Wastegate Systems

In wastegate t/housing sub-assemblies and wastegate turbine housing kits, the Hose Clamp plays a vital role in securing hoses that regulate the flow of exhaust gases. This helps in maintaining the desired backpressure and ensuring that the turbocharger operates within safe parameters.

Importance in Gauge and Oil Level Systems

When integrated with gauge and oil level systems, the Hose Clamp ensures that hoses remain connected to sensors and gauges, providing accurate readings. This is essential for monitoring engine health and performance, allowing for timely maintenance and adjustments.

Role in Hose and Turbocharger Kits

In comprehensive hose kits and turbocharger kits, the Hose Clamp is used extensively to secure various hoses that connect different components. This includes connections to the turbine housing, pre-chamber set, and other critical parts, ensuring a cohesive and leak-free system.

Application in Aftermarket and Repair Kits

For aftermarket turbochargers and turbocharger repair kits, the Hose Clamp is indispensable. It ensures that all hoses are securely attached, maintaining the performance and reliability of upgraded or repaired turbocharger systems.

Use in Core Assembly and Performance Kits

In core assemblies and performance kits, the Hose Clamp helps in securing hoses that are part of enhanced engine systems. This includes connections to pre-set actuator kits and variable geometry turbocharger actuator kits, ensuring that all components work in unison for optimal engine performance.

Conclusion

The Cummins 3535215 Hose Clamp is a critical component in maintaining the integrity and efficiency of various engine systems in commercial trucks. Its robust design, ease of installation, and resistance to environmental factors make it a reliable choice for securing hoses in critical applications. Regular maintenance and proper installation are essential to ensure the longevity and performance of this part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Barton, David C, and John D Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩ -

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 5504546.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.