This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3627907 Flexible Hose is a component designed for use in commercial truck systems. It serves as a conduit for various fluids within the truck’s operational framework, ensuring efficient and reliable performance. This hose is integral to maintaining the functionality of connected systems by providing a flexible yet durable pathway for fluid transfer 3.

Basic Concepts of Flexible Hoses

Flexible hoses are utilized across various automotive systems to transport fluids such as coolant, fuel, and hydraulic fluids. They are designed to accommodate movement and vibration, which are common in vehicle operations. Unlike rigid pipes, flexible hoses can bend and twist without compromising the flow of fluids, making them suitable for applications where space constraints and dynamic movement are factors 1.

Purpose of the 3627907 Flexible Hose

The Cummins 3627907 Flexible Hose is specifically engineered to connect different components within a truck’s system, facilitating the transport of fluids between them. It plays a role in ensuring that fluids reach their intended destinations without leakage or restriction. This hose is typically used in systems where flexibility is required to accommodate the movement of engine components or to navigate around obstacles within the truck’s chassis 3.

Key Features

The Cummins 3627907 Flexible Hose boasts several key features that enhance its performance. It is constructed from materials that offer high flexibility and durability, allowing it to withstand the rigors of commercial truck operations. The hose’s design includes reinforced layers to prevent kinking and ensure a consistent flow of fluids. Additionally, it is engineered to resist common degradative factors such as heat, pressure, and chemical exposure, which are prevalent in truck environments 2.

Benefits

Utilizing the Cummins 3627907 Flexible Hose provides several advantages. Its flexible nature reduces the risk of leaks that can occur with rigid hoses, especially in applications where movement is a factor. The hose’s durable construction contributes to the overall reliability of the truck’s system, minimizing the need for frequent replacements. Moreover, its design helps in reducing maintenance costs and downtime associated with hose failures 3.

Installation Considerations

When installing the Cummins 3627907 Flexible Hose, it is important to follow guidelines to ensure proper integration within the truck’s system. This includes selecting the correct fittings to match the hose’s specifications, securing the hose in place to prevent movement that could lead to wear or disconnection, and ensuring that the hose is aligned correctly to avoid kinks or obstructions in the fluid flow 1.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. To address these problems, regular inspections should be conducted to identify signs of wear or damage. If a leak is detected, the source should be located and repaired or replaced as necessary. Kinks can often be resolved by rerouting the hose or replacing sections that have become compromised. Degradation may require replacement of the hose to ensure continued system integrity 2.

Maintenance Tips

To prolong the service life of the Cummins 3627907 Flexible Hose, regular maintenance is recommended. This includes periodic inspections for signs of wear, such as cracks, bulges, or soft spots, which could indicate impending failure. Cleaning the hose and its connections can prevent buildup that might impede fluid flow. Additionally, ensuring that the hose is properly supported and not subjected to unnecessary stress can help maintain its condition over time 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range is designed to meet the demanding requirements of commercial vehicle operators, providing solutions that enhance performance, efficiency, and durability 3.

Role of Part 3627907 Flexible Hose in Engine Systems

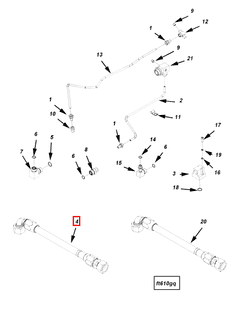

The Cummins part 3627907, a Flexible Hose, is designed to integrate seamlessly with various engine models, ensuring optimal performance and durability. This part is engineered to fit within the engine systems of the K38 and K50 engines, providing a critical connection between different components.

For the K38 engine, the Flexible Hose 3627907 is specifically tailored to accommodate the unique layout and requirements of this engine model. Its flexibility allows it to adapt to the precise angles and distances necessary for efficient fluid transfer, minimizing stress and wear on the hose.

Similarly, in the K50 engine, the part 3627907 is engineered to meet the stringent demands of this engine’s design. The hose’s flexibility ensures it can handle the dynamic movements and vibrations inherent in engine operation, maintaining a secure and reliable connection throughout.

Both engines benefit from the use of this flexible hose, as it provides a seamless integration that enhances overall engine performance and longevity. The design of the hose ensures it can withstand the operational conditions of these engines, contributing to their efficiency and reliability 3.

Conclusion

The Cummins 3627907 Flexible Hose is a vital component in the efficient operation of commercial truck systems. Its design and features make it well-suited for the dynamic and demanding environments of truck engines, providing reliable fluid transfer and contributing to the overall performance and durability of the vehicle.

-

John Dixon, Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition, Cengage Learning, 2014.

↩ ↩ -

Michael Hilgers, Alternative Powertrains and Extensions to the Conventional Powertrain, Springer Nature, 2023.

↩ ↩ -

Martynn Randall, Haynes Manual on Diesel Engines, Haynes Publishing, 2015.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.