This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3628889 Flexible Hose is a component designed for use in commercial trucks. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Flexible Hoses

Flexible hoses are used in various automotive applications to connect different parts of a system, allowing for movement and flexibility where rigid pipes might not be suitable. They are designed to transport fluids such as coolant, fuel, or air, and are crucial for systems that require components to move or flex during operation. Flexible hoses are typically made from materials that can withstand the pressure and temperature of the fluids they carry, as well as the physical stresses of the environment in which they operate 1.

Purpose of the Cummins 3628889 Flexible Hose

This Cummins part is designed to connect specific components within a truck’s system, facilitating the transport of fluids. It plays a role in ensuring that fluids can move between parts that may not be fixed in position, accommodating the natural movements and vibrations of the vehicle. This hose is integral to maintaining the integrity of the fluid pathways within the truck, ensuring that systems operate smoothly and efficiently 2.

Key Features

3628889 is constructed with a focus on durability and performance. It is made from high-quality materials that offer resistance to wear, tear, and the effects of various fluids. The hose’s flexibility allows it to bend and move without kinking, which is important for accommodating the dynamic environment of a commercial truck. Additionally, it is designed to withstand a range of temperatures and pressures, ensuring reliable performance under varying conditions 3.

Benefits

Using this part provides several advantages. Its flexibility allows for greater movement and accommodation of the truck’s components, reducing the risk of damage from rigid connections. The hose’s durability ensures long-lasting performance, even under demanding conditions. Furthermore, its design contributes to the overall efficiency of the truck’s systems by ensuring smooth and uninterrupted fluid flow.

Installation Considerations

When installing this Cummins part, it is important to follow guidelines to ensure proper fitting and secure connection. This includes checking for compatibility with the truck’s system, using the correct fittings, and ensuring that the hose is not twisted or kinked. Proper installation is key to maintaining the hose’s performance and longevity.

Troubleshooting Common Issues

Common issues with flexible hoses include leaks, kinks, and degradation over time. Regular inspections can help identify these problems early. If a leak is detected, the hose should be checked for proper installation and integrity. Kinks can often be resolved by repositioning the hose, while degradation may require replacement of the hose to ensure system reliability.

Maintenance Tips

Regular maintenance of this part is important for ensuring its longevity and reliability. This includes periodic inspections for signs of wear, leaks, or damage. Replacement guidelines should be followed to ensure that the hose is replaced before it fails, maintaining the efficiency and safety of the truck’s systems.

Safety Precautions

When handling, installing, or maintaining this Cummins part, it is important to observe safety measures to prevent accidents. This includes wearing appropriate personal protective equipment, ensuring the truck is turned off and cooled down before beginning work, and following all manufacturer guidelines for installation and maintenance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and innovative solutions. The company’s extensive product range and commitment to excellence make it a trusted name in the industry.

Cummins Flexible Hose Part 3628889 Compatibility

This part is designed to fit seamlessly into various engine configurations, ensuring optimal performance and durability. It is engineered to meet the stringent requirements of the engines it supports, providing reliable connections and minimizing the risk of leaks or failures.

K50 Engine Group

This part is specifically engineered to fit within the K50 engine group. This engine group includes a range of models that benefit from the precise engineering and high-quality materials used in this flexible hose. The hose’s design allows for flexibility and resilience, accommodating the dynamic movements and vibrations inherent in engine operations. This ensures that the hose maintains a secure connection, even under varying operational conditions, thereby enhancing the overall reliability and efficiency of the engine system.

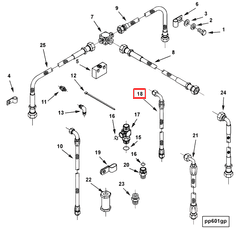

Role of Part 3628889 Flexible Hose in Engine Systems

This part is an integral component in various engine systems, facilitating the efficient transfer of fluids and gases under varying conditions. Its application spans across multiple critical areas within the engine, ensuring optimal performance and reliability.

Aftercooler Core

In turbocharged engine setups, the flexible hose connects to the aftercooler core, allowing for the transfer of cooled air from the intercooler to the intake manifold. This connection is vital for maintaining the integrity of the cooled air path, reducing the risk of leaks and ensuring that the air entering the combustion chamber is at the desired temperature.

Camshaft and Gear

The flexible hose may also be utilized in the lubrication system, specifically in routing oil to the camshaft and gear assembly. This ensures consistent lubrication, reducing wear and tear on these moving components and contributing to the longevity of the engine.

Connection to Water Outlet

In cooling systems, the flexible hose plays a significant role in connecting the water outlet to the radiator or other cooling components. This connection allows for the efficient circulation of coolant, maintaining engine temperature within safe operating limits and preventing overheating.

Injectors

For fuel systems, the flexible hose is employed to connect injectors to the fuel rail or supply line. This ensures a secure and leak-free connection, facilitating the precise delivery of fuel to the combustion chamber for optimal engine performance.

Left Bank Fuel Block Connection

In engines with multiple fuel blocks, the flexible hose is used to connect the left bank fuel block to the fuel supply system. This connection is essential for balanced fuel distribution across the engine, ensuring uniform combustion and performance.

Left Bank Oil Control Connection

Similarly, for oil control systems, the flexible hose connects the left bank oil control components, allowing for the regulated flow of oil to various engine parts. This connection is key to maintaining proper lubrication and preventing oil starvation in critical areas.

Oil Transfer Connection

The flexible hose is also crucial in oil transfer connections, facilitating the movement of oil between different engine compartments or external oil systems. This ensures that all engine parts receive adequate lubrication, enhancing engine durability and performance.

Performance Parts

In high-performance engine builds, the flexible hose is often used in conjunction with performance parts to enhance fluid dynamics and reduce restrictions. This can lead to improved engine efficiency and power output.

Plumbing and Injector Connections

For comprehensive engine plumbing, the flexible hose is a versatile component that can be used in various connections, including those to injectors and other fluid transfer points. Its flexibility allows for easier installation and maintenance, reducing the risk of damage to connected components.

Step White Smoke Kit

In specialized applications, such as the Step White Smoke Kit, the flexible hose is used to manage the introduction of water or other fluids into the exhaust system. This can be part of performance tuning or emissions control strategies, demonstrating the hose’s adaptability in diverse engine modifications.

Vent Hose

Lastly, the flexible hose serves as a vent hose in various engine systems, allowing for the release of pressure or gases from enclosed spaces. This helps in maintaining system integrity and preventing damage from excessive pressure buildup.

Conclusion

Overall, 3628889 is a versatile and essential component in engine systems, contributing to the efficient operation and longevity of the engine through its reliable fluid and gas transfer capabilities.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.