This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3633076 Plain Hose is a component designed for use in commercial truck systems. It serves as a conduit for the transfer of fluids within the truck’s operational systems, ensuring efficient and reliable performance. This hose is integral to maintaining the functionality of various truck systems by facilitating the smooth movement of fluids 1.

Basic Concepts of Plain Hoses

Plain hoses are flexible tubes used in fluid transfer systems across various industries. They are designed to convey liquids, gases, or even pneumatic signals between different components of a system. In automotive and heavy-duty truck applications, plain hoses operate under a range of conditions, from high pressure to varying temperatures, making them a versatile choice for fluid transport. Their flexibility allows for movement and vibration absorption, which is crucial in the dynamic environment of a commercial truck 2.

Purpose of the Cummins 3633076 Plain Hose

The Cummins 3633076 Plain Hose plays a specific role in the operation of a truck by transporting fluids within the engine cooling, fuel, or hydraulic systems. It ensures that fluids reach their intended destinations without leakage or contamination. This hose is engineered to withstand the pressures and temperatures associated with these systems, contributing to the overall efficiency and reliability of the truck’s operation 3.

Key Features

The Cummins 3633076 Plain Hose is characterized by several key features that enhance its performance and longevity. It is made from durable materials that resist wear, tear, and chemical degradation. The hose’s flexibility allows it to accommodate the movement and vibrations typical in truck operations, while its design ensures a secure fit within the system. These features contribute to the hose’s ability to maintain system integrity and efficiency over time 4.

Benefits

The use of the Cummins 3633076 Plain Hose offers several benefits. It contributes to improved system efficiency by ensuring a reliable fluid transfer path. The hose’s design reduces the risk of leaks, which can lead to system failures or inefficiencies. Additionally, its durability ensures a longer service life compared to other hose types, reducing the need for frequent replacements and maintenance 5.

Installation Considerations

When installing the Cummins 3633076 Plain Hose, it is important to follow guidelines and best practices to ensure proper fitting and securement. This includes selecting the correct fittings for the hose ends, ensuring a tight seal to prevent leaks, and verifying compatibility with the existing system. Proper installation is key to maximizing the hose’s performance and longevity 6.

Maintenance and Care

Maintaining the Cummins 3633076 Plain Hose involves regular inspection routines to check for signs of wear or damage. This includes looking for cracks, bulges, or leaks, which can indicate the need for repair or replacement. Following best practices for maintenance can help prolong the hose’s service life and ensure continued system reliability 7.

Troubleshooting Common Issues

Common problems associated with plain hoses, such as leaks, cracks, or degradation, can often be traced back to installation issues, environmental factors, or normal wear and tear. Troubleshooting these issues effectively involves identifying the root cause, whether it be a faulty fitting, exposure to harsh chemicals, or physical damage. Addressing these issues promptly can prevent more significant system failures 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves commercial, industrial, and transportation markets worldwide. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 3633076 Plain Hose, designed to meet the demanding requirements of commercial truck systems 9.

Compatibility of Plain Hose Part 3633076 with Cummins Engines

The Plain Hose part 3633076, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This hose is a critical component in the engine’s cooling system, ensuring efficient fluid transfer and maintaining optimal engine performance.

K38 and K50 Engines

The Plain Hose part 3633076 is compatible with the K38 and K50 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications. The hose ensures that coolant flows smoothly through the engine, preventing overheating and maintaining the engine’s efficiency.

KTA38GC CM558, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS Engines

The Plain Hose part 3633076 is also suitable for the KTA38GC CM558, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines are part of Cummins’ QSK series, which is renowned for its power and durability. The hose’s design ensures that it can handle the high-pressure environments within these engines, providing a reliable connection for coolant flow.

QSK50 CM2150 MCRS and QSK50 CM2350 K108 Engines

Lastly, the Plain Hose part 3633076 fits the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines are part of the QSK50 series, which is designed for demanding applications requiring high power output and efficiency. The hose’s compatibility with these engines ensures that coolant is effectively circulated, contributing to the engine’s longevity and performance.

Role of Part 3633076 Plain Hose in Engine Systems

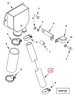

The part 3633076 Plain Hose is integral to the efficient operation of various engine components. It facilitates the movement of gases and fluids, ensuring that the engine operates within optimal parameters. Here’s how it interfaces with several key components:

Crankcase Breather System

In the crankcase breather arrangement, the Plain Hose connects the crankcase to the breather vent, allowing pressurized gases to escape. This prevents the buildup of pressure within the crankcase, which could lead to oil leaks and reduced engine efficiency. The hose works in conjunction with the crankcase breather kit to maintain a balanced pressure environment.

Oil Fill and Breather Configuration

The Plain Hose is also utilized in the oil fill and breather setup. It links the oil fill cap to the breather system, enabling the release of air as oil is added. This ensures that the oil fill process is smooth and that the crankcase does not become over-pressurized. The hose contributes to the overall integrity of the fill and breather mechanism by providing a reliable conduit for air and gases.

Dipstick and Fill & Breather Assembly

In systems where the dipstick serves a dual purpose for fill and breather, the Plain Hose plays a supportive role. It connects the dipstick tube to the breather system, allowing for the proper ventilation of the crankcase during oil level checks and additions. This setup ensures that the dipstick functions effectively without compromising the breather system’s efficiency.

Crankcase Explosion Valve Integration

When integrated with a crankcase explosion valve, the Plain Hose helps in directing the flow of gases away from the crankcase in the event of a backfire. This protects the engine’s internal components from damage and ensures that the explosion valve operates as intended.

Comprehensive Breather Vent Hose Network

The Plain Hose is a vital component in the broader breather vent hose network. It connects various points within the engine’s breather system, ensuring that all components work in harmony. This network is essential for maintaining the engine’s performance and longevity by managing pressure and facilitating the efficient circulation of gases and fluids.

Conclusion

The Cummins 3633076 Plain Hose is a critical component in the efficient operation of commercial truck systems. Its design and features ensure reliable fluid transfer, contributing to the overall efficiency and reliability of the truck’s operation. Proper installation, maintenance, and troubleshooting are essential to maximize the hose’s performance and longevity.

-

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Caines, Arthur J, Haycock, Roger F, and Hillier, John E. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Cummins Inc. Engine: General Information. Bulletin Number 4960282, Owners Manual.

↩ -

Cummins Inc. Engine: General Information. Bulletin Number 4960282, Owners Manual.

↩ -

Cummins Inc. Engine: General Information. Bulletin Number 4960282, Owners Manual.

↩ -

Cummins Inc. Engine: General Information. Bulletin Number 4960282, Owners Manual.

↩ -

Cummins Inc. Engine: General Information. Bulletin Number 4960282, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.